Cu@mSiO2 core-shell nano catalyst for preparing hydrogen from ammonia borane and hydrazine borane by hydrolysis and preparation method of catalyst

A technology for hydrogen production by hydrolysis and hydrazine borane, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Catalytic performance and other issues to achieve the effect of avoiding the pre-modification process, mild reaction conditions, and avoiding performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

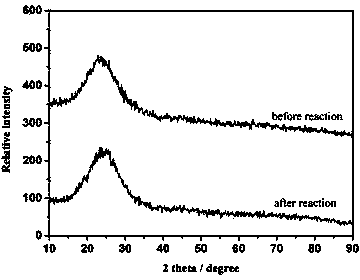

Image

Examples

Embodiment 1

[0035] 1) Dissolve 20.16 g of surfactant polyethylene glycol mono-4-nonphenyl ether in 480 ml of non-polar solvent cyclohexane, and stir at room temperature for 2 hours.

[0036] 2) Add 2.16 ml copper chloride solution (concentration: 121.5 mM) dropwise to step 1) and stir for 15 hours.

[0037] 3) Add 2.16 ml concentrated ammonia water to step 2), and continue stirring for 2 hours.

[0038] 4) Add 3.6 ml tetraethyl orthosilicate to the reaction solution obtained in step 3), and continue to stir for 48 hours.

[0039] 5) Add the reaction solution obtained in step 4) to methanol solution for phase separation, then centrifuge, wash, and dry to obtain CumSiO with a core-shell structure loading of about 2.4 wt.%. 2 Core-shell structured nanocatalysts.

Embodiment 2

[0041] In Example 1, step 1) of polyethylene glycol mono-4-nonphenyl ether was changed to polyoxyethylene (20) hexadecyl ether, and other steps were the same as in Example 1 to obtain a core-shell structure with a loading capacity of about 2.4 wt.% CumSiO 2 Core-shell structured nanocatalysts.

Embodiment 3

[0043] In Example 1, step 1) polyethylene glycol mono-4-nonphenyl ether was changed to nonylphenol polyoxyethylene ether, and the other steps were the same as in Example 1 to obtain a core-shell structure with a loading capacity of about 2.4 wt.%. CumSiO 2 Core-shell structured nanocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com