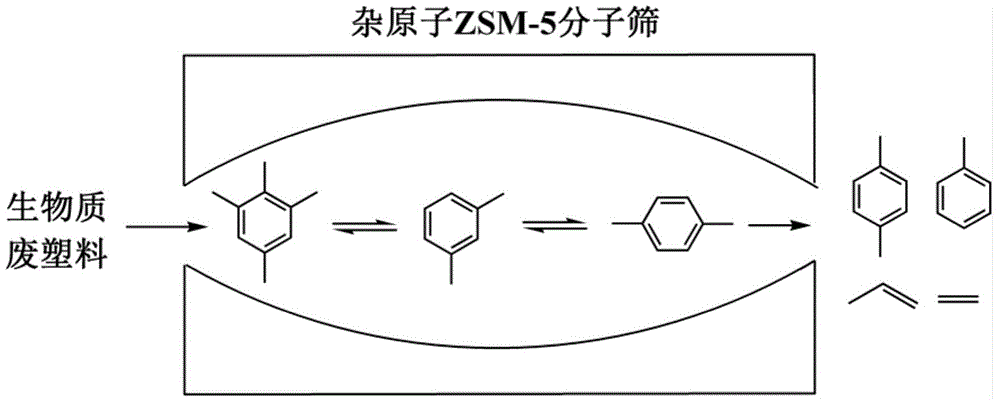

Method for synthesizing heteroatomic ZSM-5 molecular sieve and application thereof

A technology of ZSM-5 and synthesis method, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and preparation of liquid hydrocarbon mixtures, etc., which can solve the problems of difficult precise control of pore size regulation, no improvement of xylene selectivity, and reduction of xylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

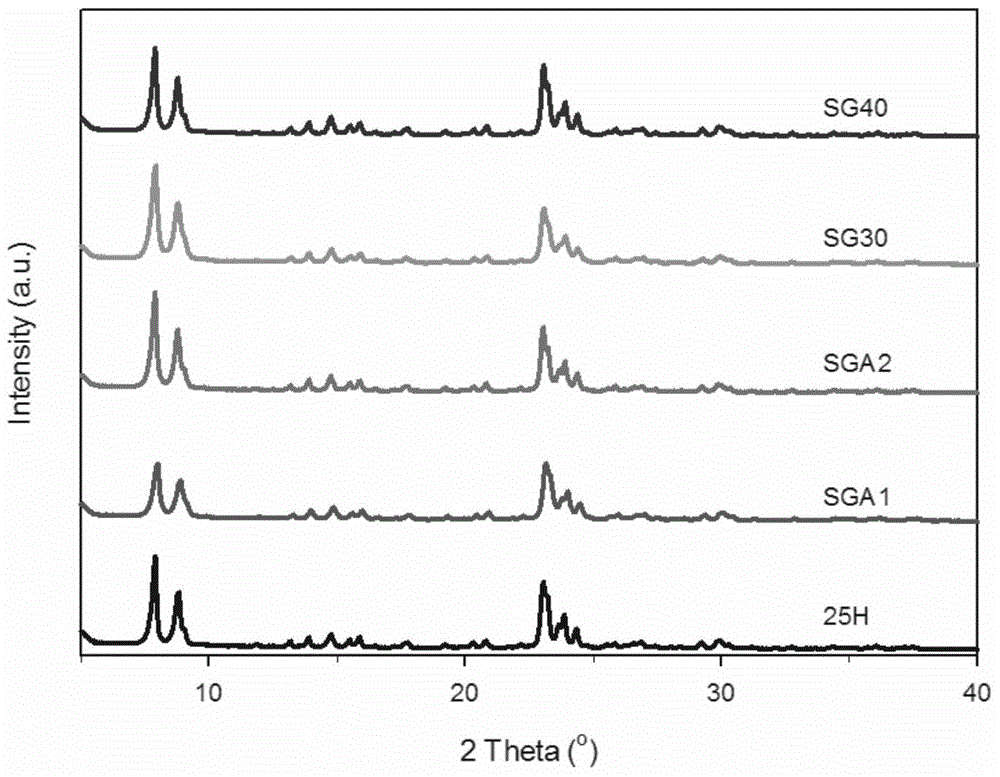

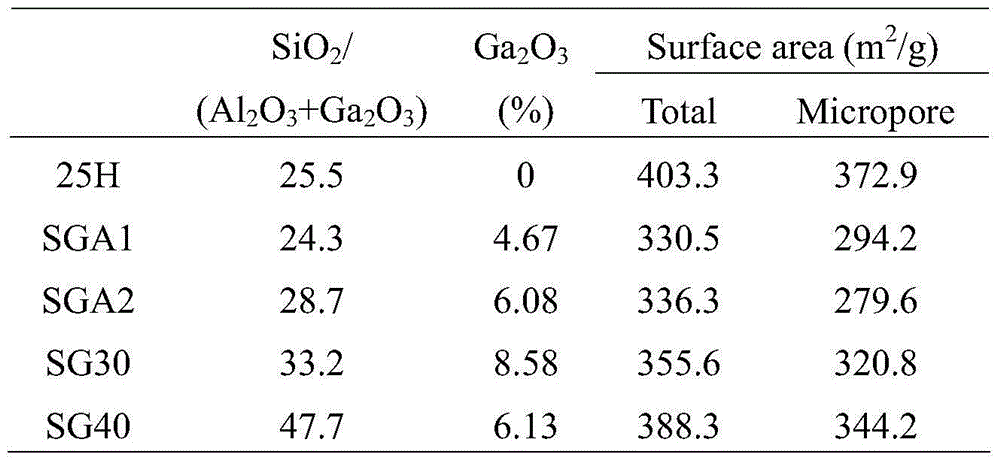

[0049] Embodiment 1 molecular sieve preparation

[0050] (1) Silica sol is the silicon source, aluminum sulfate is the aluminum source, gallium sulfate is the gallium source, sodium hydroxide is the mineralizer, and the organic template is tetrapropylammonium hydroxide (TPAOH). The raw materials are converted into moles of oxides The ratio is:

[0051] SiO 2 :Al 2 o 3 : Ga 2 o 3 :NaOH:TPAOH:H 2 O=25:0.7:0.7:1:5:2000

[0052] (2) Add the gallium source and the aluminum source into the template solution (concentration 2mol / L) and stir for 30 minutes; then add sodium hydroxide and stir for 30 minutes; move the above solution to the aqueous solution of the silicon source (commercially available silica sol, 25% silicon dioxide), stirring was continued for 120 minutes to form a uniform sol-gel system. The rest of the water and gallium sulfate in the raw material ratio are made into an aqueous solution and added.

[0053] (3) The above sol-gel was moved to a reaction kettle ...

Embodiment 2

[0056] Embodiment 2: molecular sieve preparation

[0057] (1) Orthoethyl silicate is the silicon source, aluminum sulfate is the aluminum source, gallium sulfate is the gallium source, sodium hydroxide is the mineralizer, and the organic template is tetrapropylammonium hydroxide (TPAOH). The molar ratio of the substance is:

[0058] SiO 2 :Al 2 o 3 : Ga 2 o 3 :NaOH:TPAOH:H 2 O=25:0.4:0.9:1:5:2000

[0059] (2) Add the gallium source and the aluminum source into the template solution (solution concentration 1mol / L), and stir for 30 minutes; then add sodium hydroxide, and stir for 30 minutes; move the above solution to the aqueous solution of the silicon source (commercially available positive silicon Acetate ethyl ester solution, 28.4% silicon oxide), and continue stirring for 120 minutes to form a uniform sol-gel system. The rest of the water and gallium sulfate in the raw material ratio are made into an aqueous solution and added.

[0060] (3) The above sol-gel was mo...

Embodiment 3

[0062] Embodiment 3 molecular sieve preparation

[0063] (1) Orthosilicic acid is the silicon source, gallium nitrate is the gallium source, sodium hydroxide is the mineralizer, and the organic template is tetrapropylammonium hydroxide (TPAOH). The molar ratio of raw materials converted to oxides is:

[0064] SiO 2 : Ga 2 o 3 :NaOH:TPAOH:H 2 O=25:1.3:1:5:2000

[0065] (2) Add the gallium source into the template solution (concentration 2mol / L), stir for 30 minutes; then add sodium hydroxide, and stir for 30 minutes; move the above solution to the aqueous solution of the silicon source (commercially available ethyl orthosilicate solution , 28.4% silicon dioxide), stirring was continued for 120 minutes to form a uniform sol-gel system. The rest of the water and gallium nitrate in the raw material ratio are made into an aqueous solution and added.

[0066] (3) Move the above-mentioned sol-gel to a reaction kettle lined with polytetrafluoroethylene, and then put it into a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com