Ethylene-propylene-diene monomer (EPDM) and preparation method

A technology of EPDM rubber and compounds, which is applied in the field of polymer material preparation, can solve the problems of reduced catalyst activity and low catalytic efficiency, and achieve the effects of appropriate double bond content, high catalytic efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of EPDM rubber, comprising:

[0022] Under the action of vanadium-based catalysts, alkylaluminum compounds and organic chlorides, polyfunctional compounds, propylene and ethylene are polymerized to obtain EPDM rubber; the multifunctional compounds include trimethylolpropane Acrylates, diethylene glycol diacrylate, divinylbenzene or N,N'-methylenebisacrylamide.

[0023] The present invention uses the multifunctional compound as the third monomer to carry out polymerization reaction with ethylene and propylene, and the addition of the third monomer will not reduce the catalytic activity of the vanadium-based catalyst. Compared with the prior art, the present invention provides The preparation method of EPDM rubber has higher catalytic efficiency. In addition, the low price of the multifunctional compound makes the preparation method of the EPDM rubber provided by the present invention relatively low in cost; moreover, t...

Embodiment 1

[0043] Replace the reactor with nitrogen for 3 times and keep the seal of the reactor; under the condition of stirring, add 0.1mmol of VOCl in the reactor successively 3 , 2.0mmol of Al 2 (C 2 h 5 ) 3 Cl 3 , 2.0mmol of Al 3 (C 2 h 5 ) 3 Cl 3 With the mixed solution of the trimethylolpropane triacrylate (TMPTA) of 1.1g, the ethyl trichloroacetate (ETCA) of 0.6mmol and the hexane of 300mL after mixing, in the mixture that passes through is 1: 2 mixed gas of ethylene and propylene, carry out the polymerization reaction at 0.4MPa, 20°C for 30min; add 5% hydrochloric acid ethanol solution to the obtained reaction product, wash with ethanol, vacuum the washed reaction product After drying, 20.5 g of EPDM rubber was obtained.

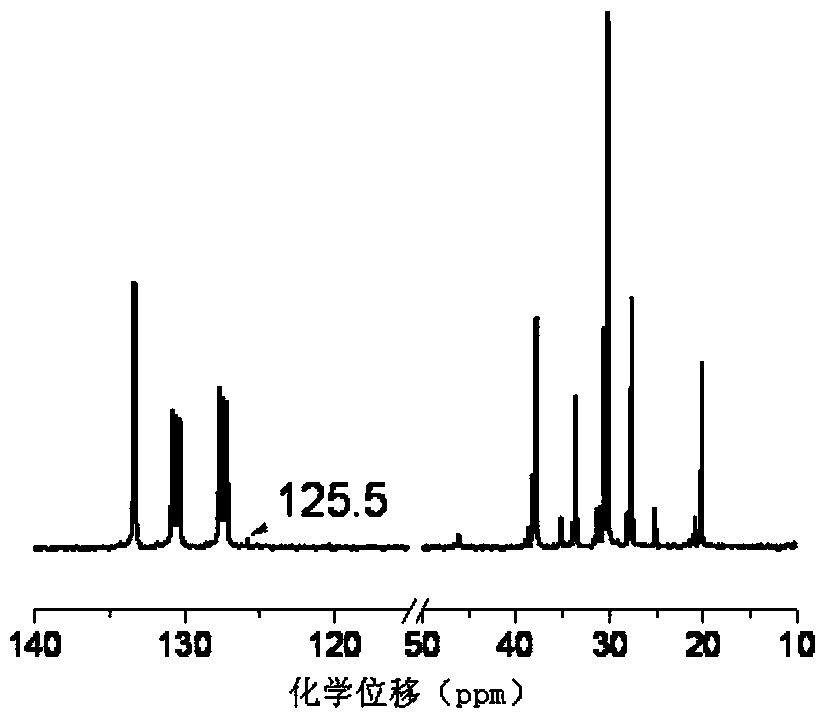

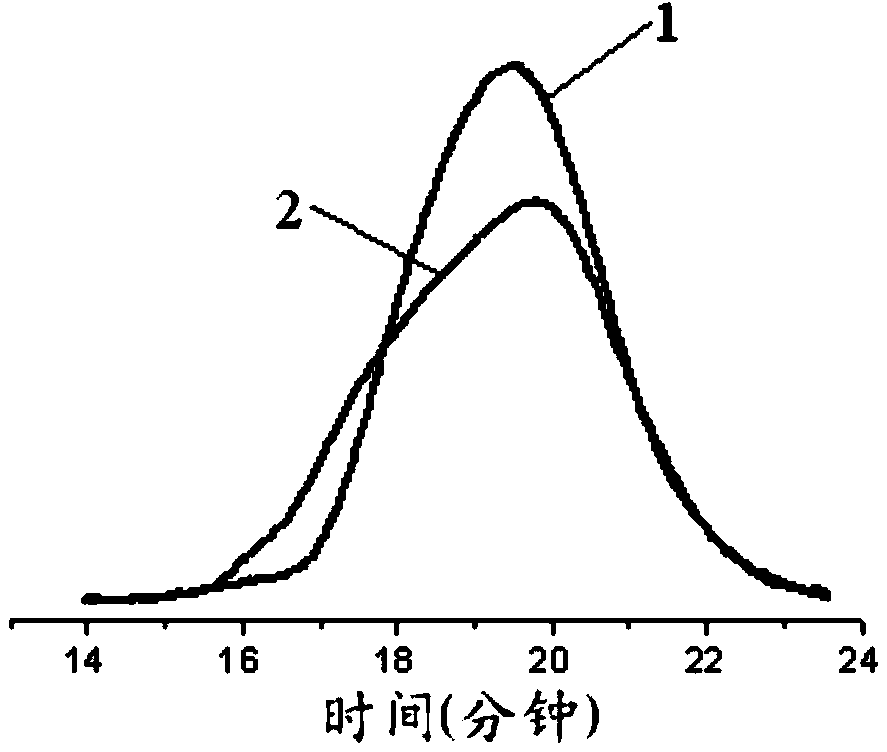

[0044] The EPDM rubber that the embodiment of the present invention 1 obtains is carried out nuclear magnetic resonance test, test result is as follows figure 1 as shown, figure 1 For the nuclear magnetic resonance spectrogram of the EPDM rubber th...

Embodiment 2

[0047] Replace the reactor with nitrogen for 2 times and keep the seal of the reactor; under the condition of stirring, add 0.1mmol of VOCl to the reactor successively 3 , 6.0mmol of Al(C 2 h 5 ) 2 Cl 2 , 0.6mmol of ethyl trichloroacetate, 1.06g of TMPTA and 300mL of hexane are mixed, and a mixed gas of ethylene and propylene with a mass ratio of 1:3 is introduced into the obtained mixture at 0.4MPa and 30°C. 30min polymerization reaction; add 5% ethanol hydrochloric acid solution to the obtained reaction product, wash with ethanol, and vacuum dry the washed reaction product to obtain 15.6 g of EPDM rubber.

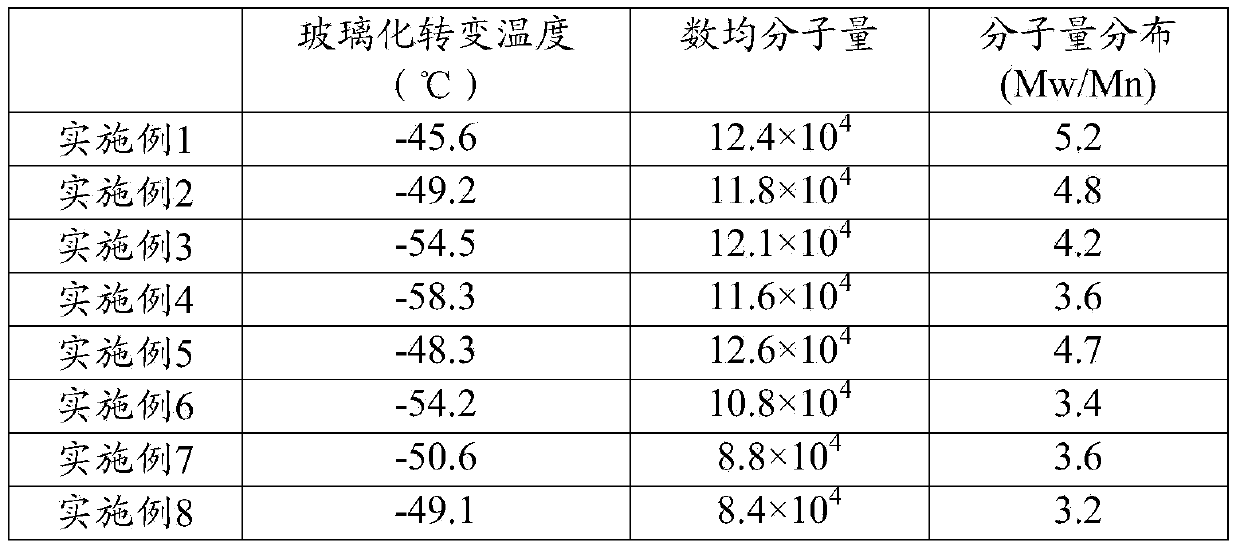

[0048] Test the double bond content of the EPDM rubber obtained in Example 2 of the present invention according to the method described in Example 1, and the test result is that the double bond mass content of the EPDM rubber obtained in Example 2 of the present invention is 6.2%; According to the method described in Example 1, the glass transition temperature, number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com