Preparation method of three-dimensional porous hexagonal boron nitride

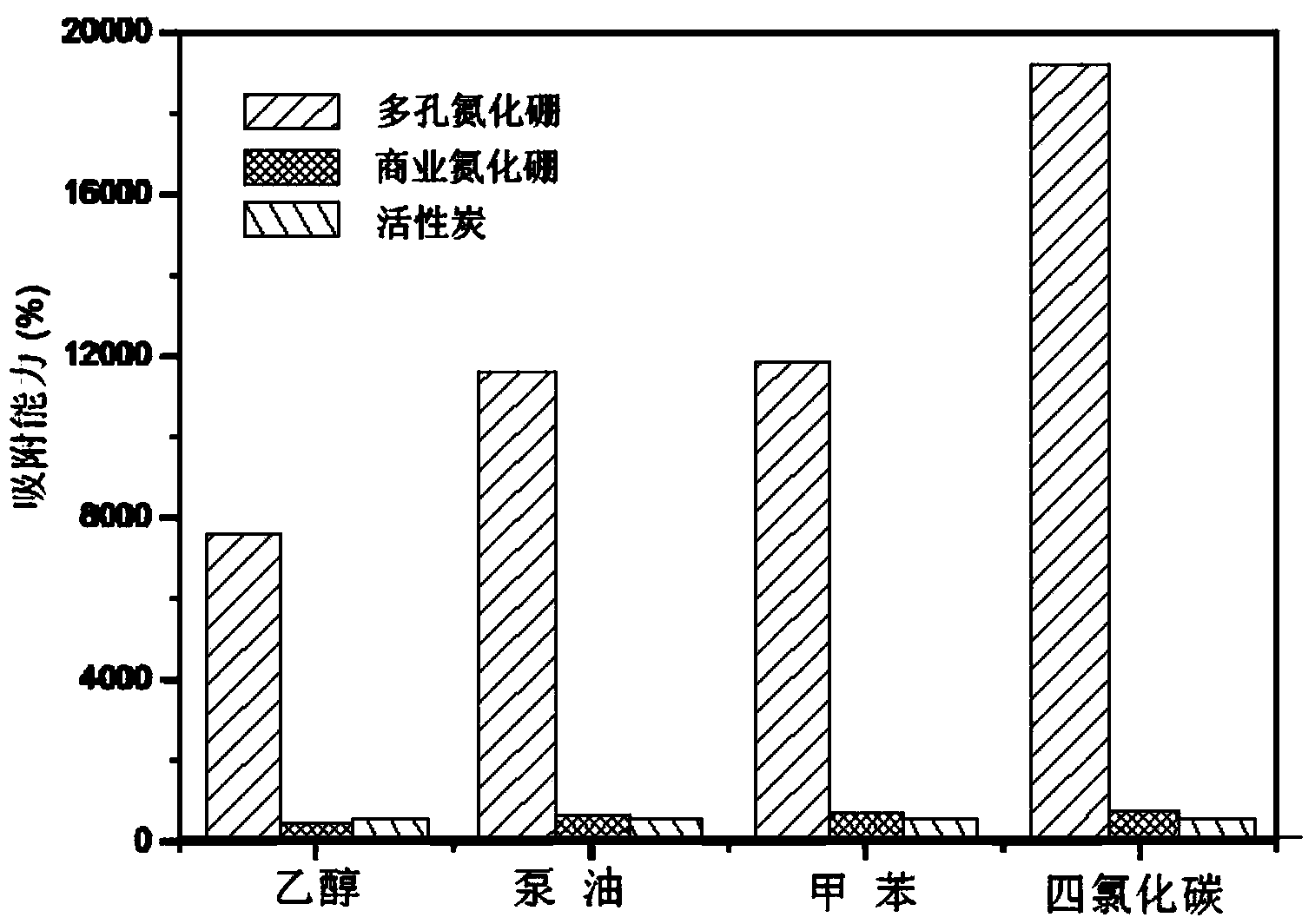

A hexagonal boron nitride, three-dimensional porous technology, used in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high apparent density of materials, complicated preparation methods, single pore structure, etc., and achieve low apparent density. , The effect of cheap equipment and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of hexagonal boron nitride comprises the following steps:

[0046] (1) Evenly mix 1 part of borane ammonia, the precursor of boron nitride, with 0.4 part of active agent thiourea, and put it into a corundum crucible;

[0047] (2) Place the corundum crucible in the middle of the heating zone of the high-temperature horizontal tube furnace, and evacuate the high-temperature tube furnace to 10pa;

[0048] (3) Pass inert gas N at a gas flow rate of 40 sccm 2 , 80min from room temperature to 1200°C and react for 2h; 60min to cool to 700°C and then naturally cool to room temperature to obtain a three-dimensional porous hexagonal boron nitride material.

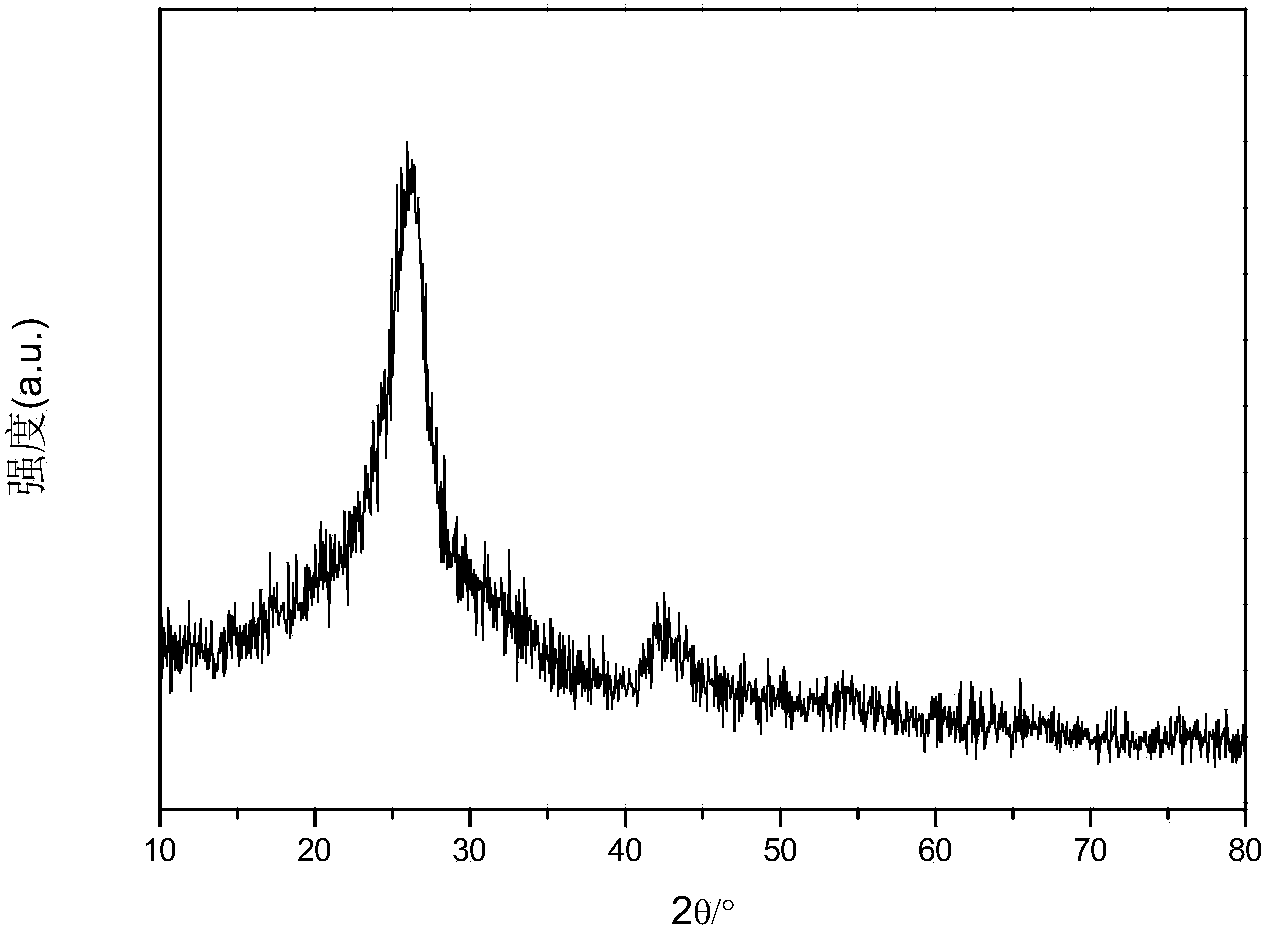

[0049] The hexagonal boron nitride obtained according to the above method presents a white light and fluffy three-dimensional porous sheet structure, and its apparent density is as low as 2.7 mg / cm 3 , The adsorption capacity of carbon tetrachloride is as high as 19100wt%, and the BET specific surface...

Embodiment 2

[0051] Hexagonal boron nitride was prepared by the same method as in Example 1 except that no active agent was added.

[0052] From this experiment, the apparent density can be obtained as 27.8mg / cm 3 Three-dimensional porous hexagonal boron nitride with a yield of 53%. In the absence of cross-linking of active agents, the thickness of the boron nitride sheet increases, the area of the sheet decreases, and the yield decreases.

Embodiment 3

[0054] Hexagonal boron nitride was prepared by the same method as in Example 1, except that the mass ratio of active agent thiourea to borane ammonia was changed to 0.2:1.

[0055] From this experiment, an apparent density of 7.1 mg / cm can be obtained 3 , Hexagonal boron nitride with a three-dimensional porous sheet structure with a yield of up to 62%. The content of thiourea is relatively small, and the cross-linking effect is not significant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com