Method of extracting and fermenting and separating 1,3-propylene glycol in fermentation liquor by coupling

A technology of propylene glycol and fermented liquid, which is applied in the field of bioengineering, can solve the problems of difficult recovery of raw materials, salt, and bacteria, hindering the evaporation of fractions, and small separation ability, so as to improve the utilization rate of raw materials, reduce the discharge of waste water, and have low-cost sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] 2. Preparation of 1,3-propanediol fermentation broth:

[0043] (1) Klebsiella was inoculated into the seed medium, and cultured on a shaking table at 37° C. and 200 rpm for 24 hours;

[0044] (2) Insert the bacterium culture liquid of step (1) into the fermentation medium according to the inoculum size (v / v) of 10%, the pH value of the fermentation liquid is 7.0, the initial glycerol concentration of the fermentation liquid is 40g / L, and the , 200rpm under the shaking table for 24h, to get 1,3-propanediol fermentation broth, at this time the OD of the fermentation broth 600nm reached 8.47, the concentration of 1,3-propanediol reached 68.3g / L, the concentration of remaining glycerin was 15.3g / L, and the mass conversion rate of glycerol to 1,3-propanediol was 43.7%.

[0045] Pretreatment of 1,3-propanediol fermentation broth: the 1,3-propanediol fermentation broth obtained in the above 2 contains bacteria, which can be pretreated by flocculation, filtration, microfiltrat...

Embodiment 1

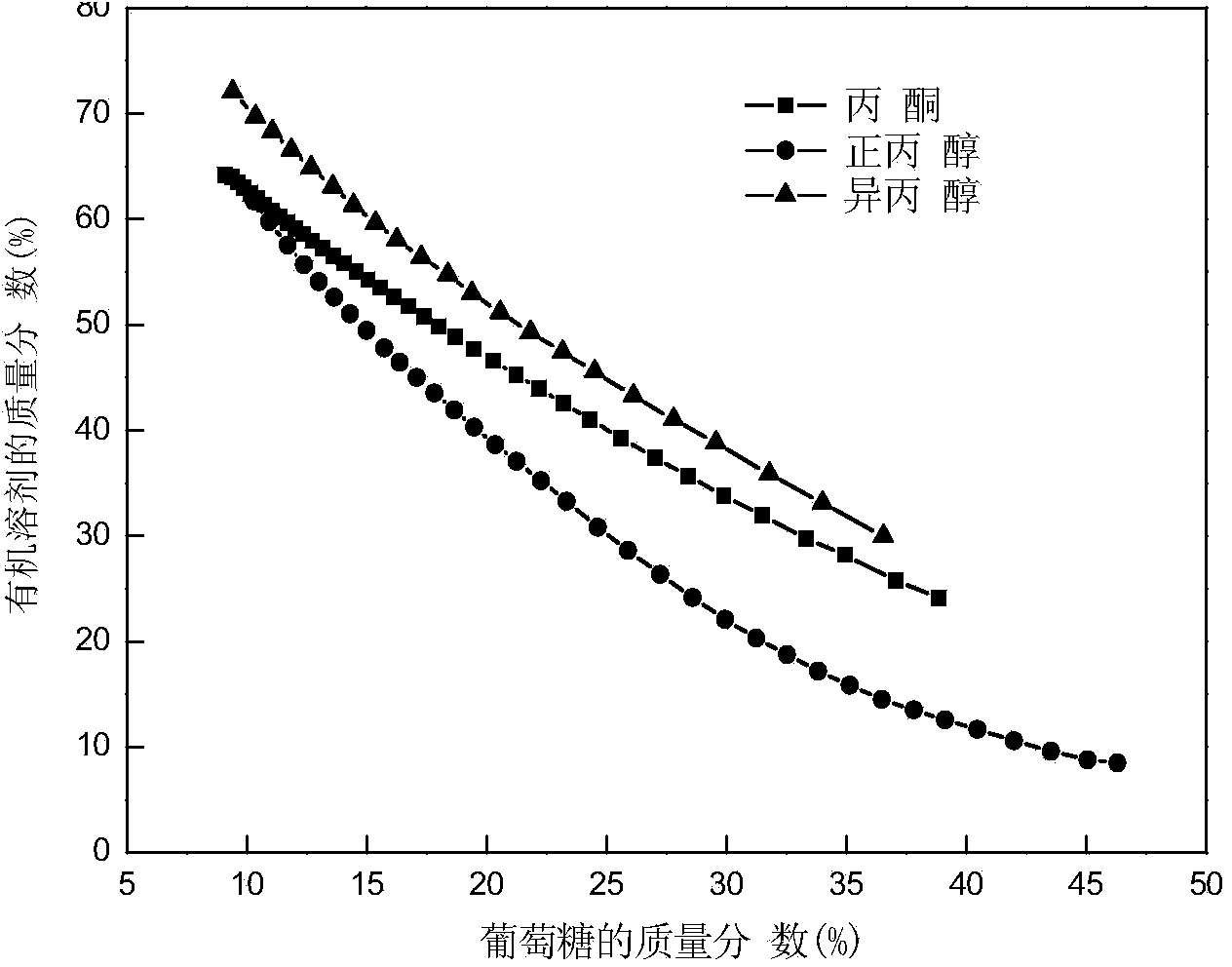

[0065] Embodiment 1 The phase formation law of glucose and three kinds of organic solvents

[0066]Use the turbidity method to draw the phase diagram of the two-phase system, prepare a nearly saturated aqueous glucose solution, add an organic solvent to it and mix evenly, record the mass fraction of the organic solvent and sugar when it happens to be turbid, and add a certain amount of distilled water to the system. Repeat the above steps after clarification, and draw the phase diagram of the aqueous two-phase system with the mass fraction of glucose as the horizontal axis and the mass fraction of the organic solvent as the vertical axis after the operation is completed.

[0067] The phase diagrams of the systems composed of different concentrations of glucose and acetone, n-propanol, and isopropanol are shown in figure 1 show. figure 1 The results show that the system composed of glucose and n-propanol has a relatively wide phase-forming range, and the phase-forming ability ...

Embodiment 2

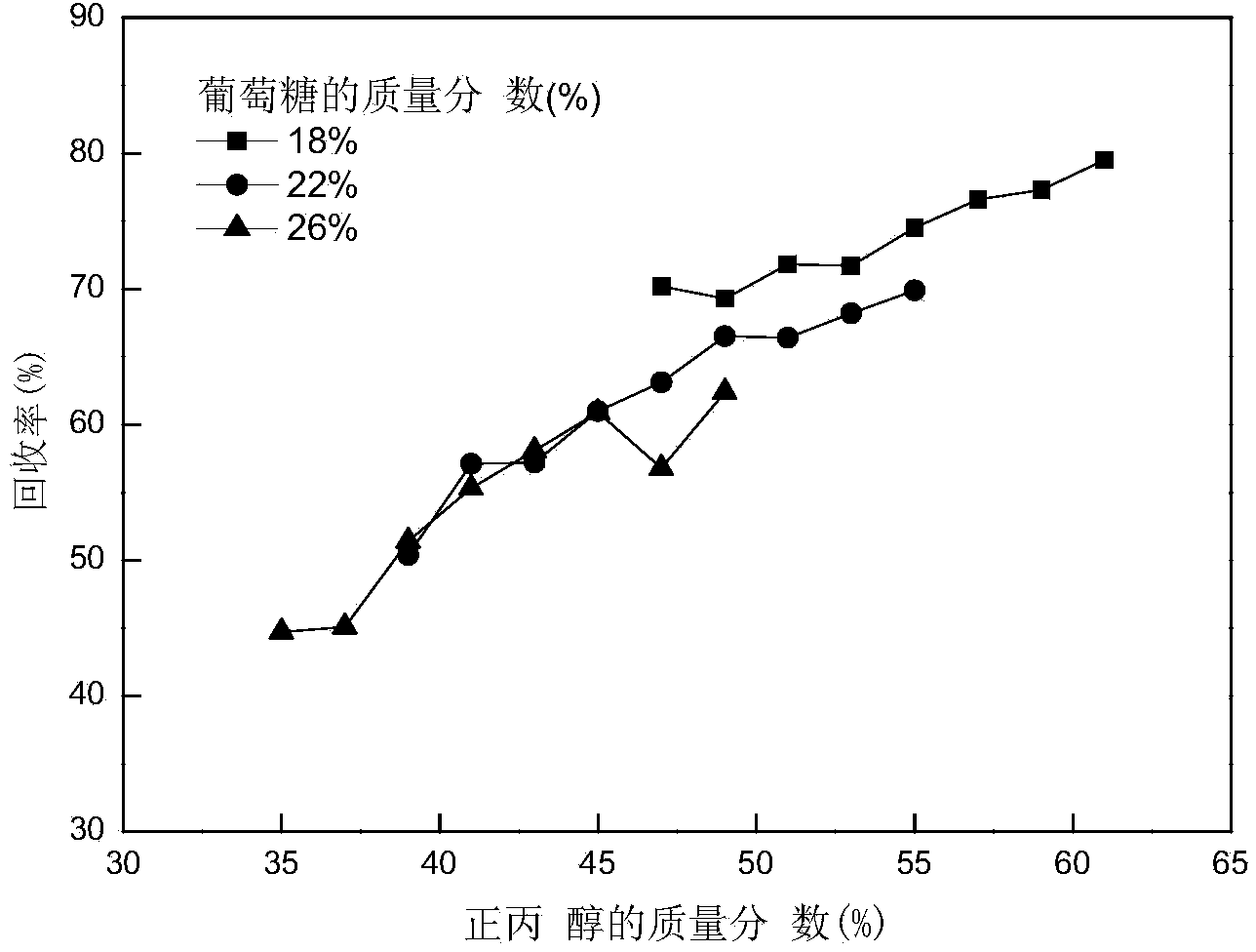

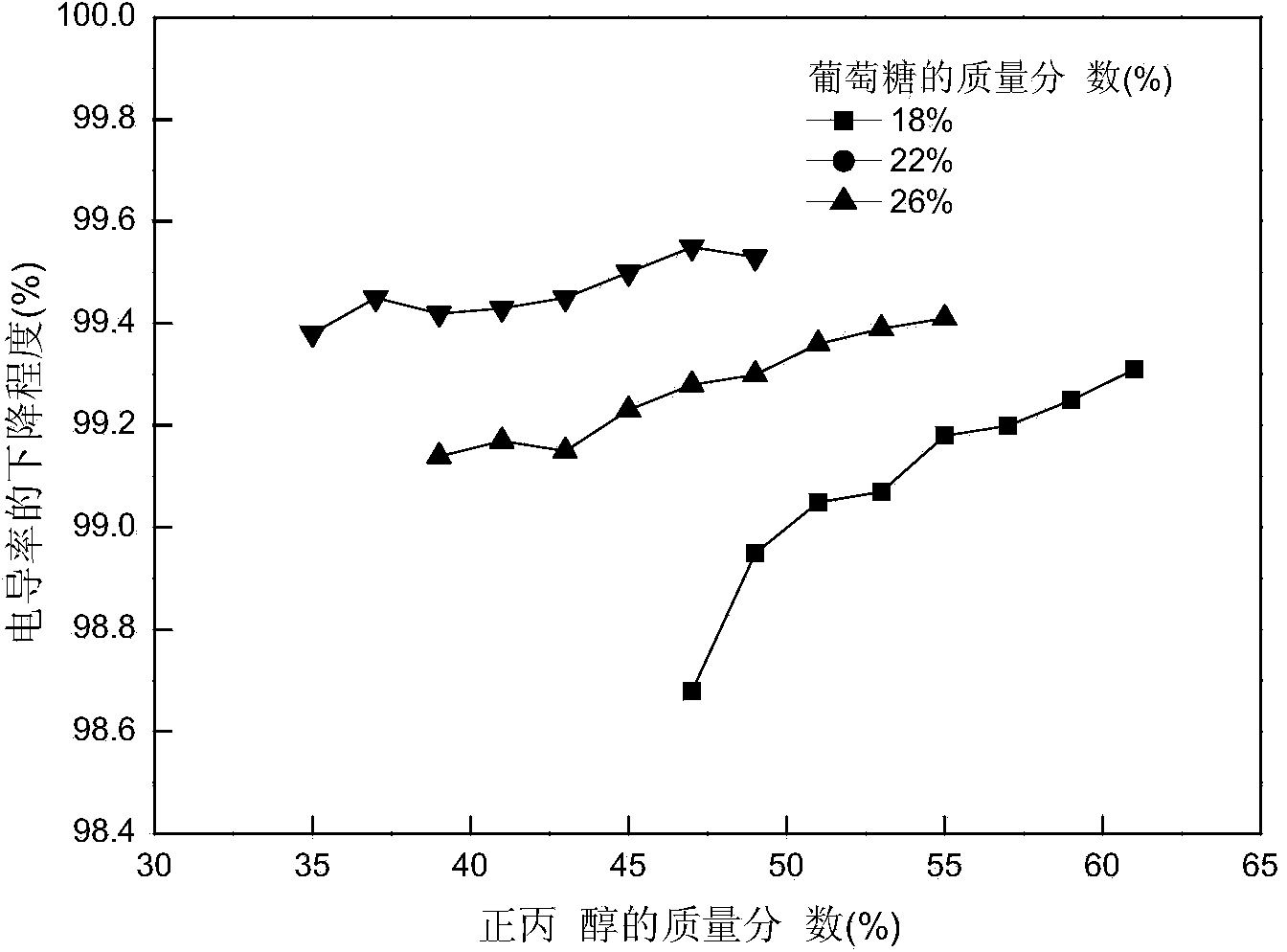

[0068] Embodiment 2 The influence of different sugar / organic solvent systems on 1,3-diol separation effect

[0069] The simulated solution of 1,3-propanediol fermentation broth was prepared with pure 1,3-propanediol and distilled water. Wherein, the concentration of 1,3-propanediol in the 1,3-propanediol simulated liquid is 60g / L. Glucose was added to the 1,3-propanediol simulated liquid until it was completely dissolved to obtain a sugar-containing mixed liquid, and an organic solvent was added to the sugar-containing mixed liquid to form an extraction system. In the extraction system, the sugar, organic solvent, and 1,3-propanediol simulated liquid The mass percentages were 22%, 55%, and 23% (ω / ω), and the system was mixed uniformly, left to stand at room temperature to obtain a two-phase aqueous system, and samples were taken to determine the content of 1,3-propanediol in the upper phase and the lower phase. Concentration, calculate the distribution coefficient (K) and rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap