A new process for preparing sodium thiocyanate

A technology of sodium thiocyanate and a new process, applied in the direction of thiocyanate, can solve the problems of inability to eliminate environmental pollution, water source pollution, low purity of sodium thiocyanate, etc., achieve a wide range of industrial applications, reduce production costs, raw materials low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

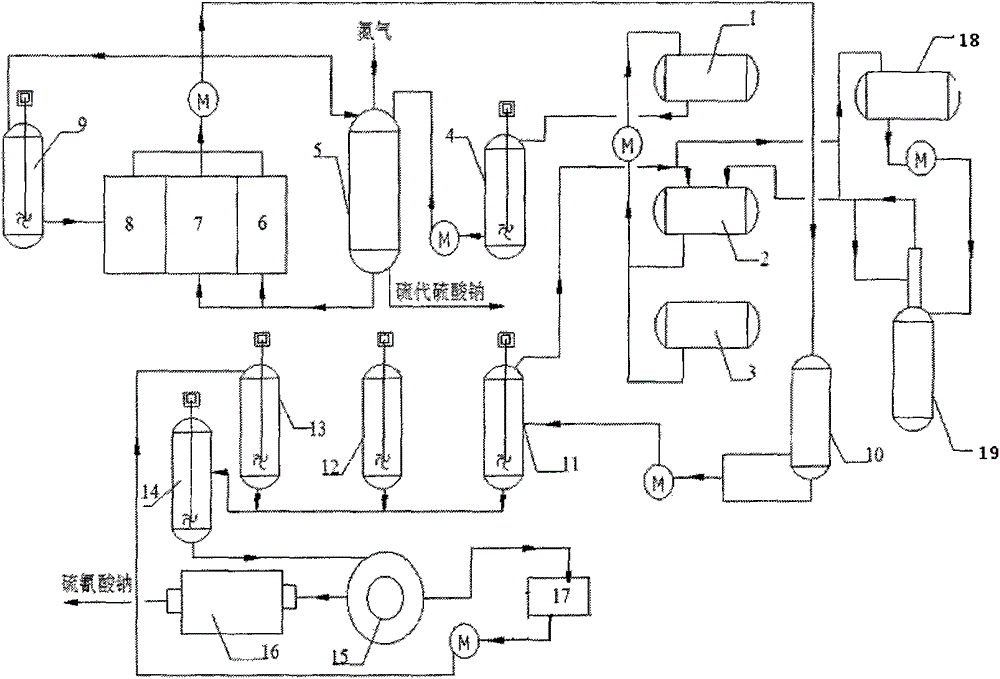

[0033] A kind of novel technique for preparing sodium thiocyanate, comprises the steps:

[0034] 1) Dissolved in methanol

[0035] Use coking gas PDS desulfurization mixed salt as raw material; first, evaporate the coking desulfurization waste liquid to dryness to obtain mixed salt containing sodium thiocyanate, sodium sulfate and sodium thiosulfate, crush the mixed salt into blocks, and dilute the raw material methanol The methanol in tank 3 and the qualified methanol tank 2 recovered by rectification is poured into methanol mixing tank 1 to ensure that the methanol content in the mixing tank is ≥98%, and then 2 tons of methanol from methanol mixing tank 1 are added to the dissolution tank 4, Then add 1.44 tons of pulverized mixed salt, heat to 50° C. with steam, stir for 2 hours at a speed of 70 r / min, and obtain a solution.

[0036] 2) Nitrogen pressure filtration

[0037] The solution in the dissolution kettle 4 is sent into the pressure filter tank 5, and nitrogen gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com