Transition metal sulfide and graphene composite material counter electrode and preparation and application thereof

A technology of transition metals and composite materials, applied in transition metal sulfide and graphene composite counter electrode and its preparation and application, can solve the problems of limiting surface redox conversion reaction efficiency and unsatisfactory electrical conductivity, and achieve good electrical conductivity and catalytic ability, low cost and simple synthesis technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

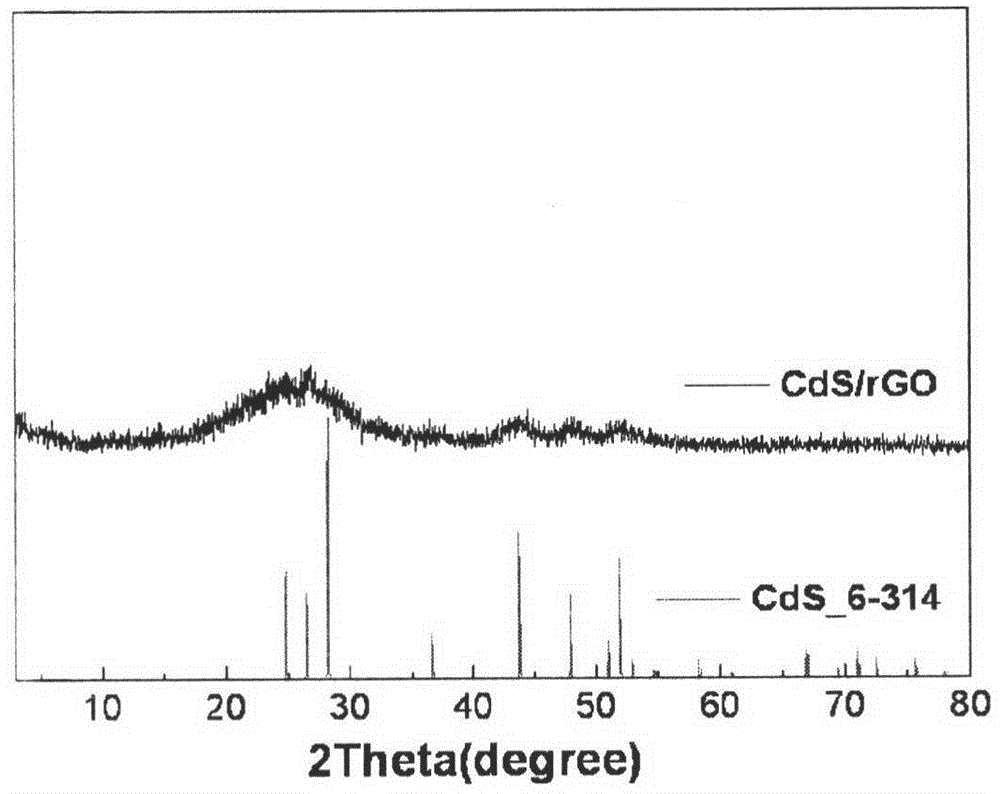

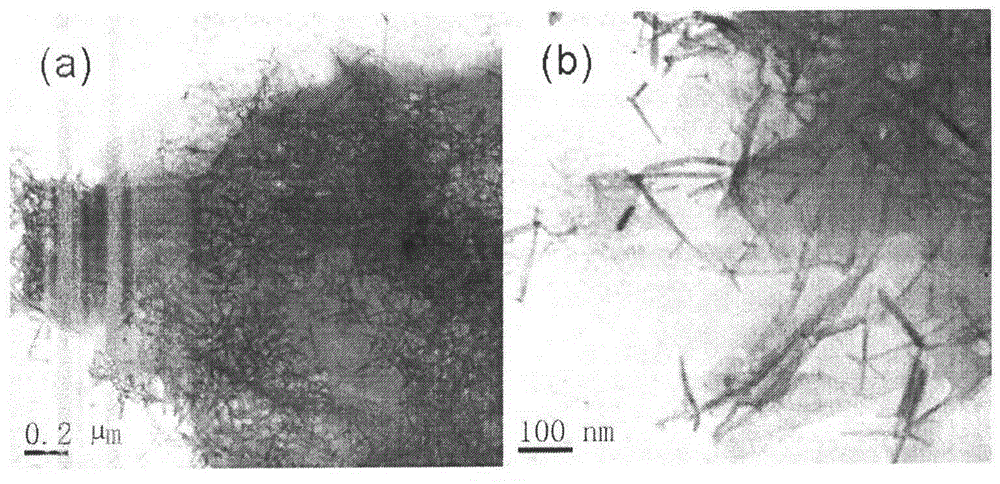

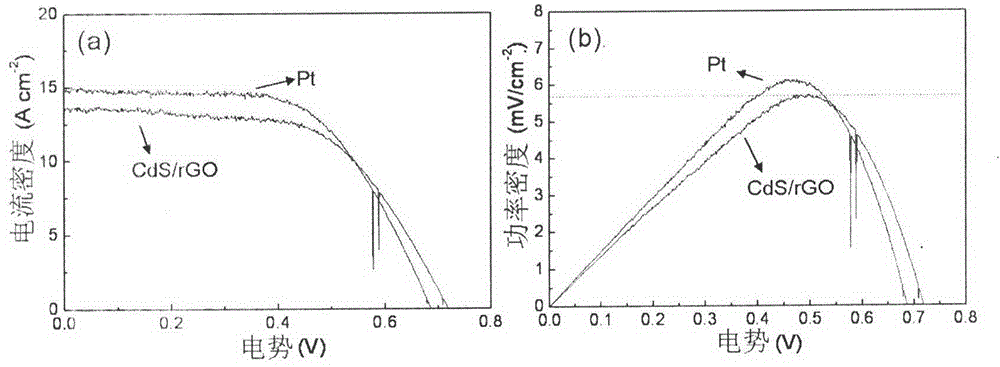

[0024] Embodiment 1: the preparation of cadmium sulfide graphene composite material counter electrode

[0025]1) Synthesis of cadmium sulfide graphene composite: cadmium chloride 5mmol, graphene oxide (GO, prepared by Hummer method) 72mg, added to 40mL ethylenediamine solvent, mixed and ultrasonically (150W, 40Hz) for 40min, the reactant Disperse and mix evenly, then add 5mmol Na which has been dissolved in 10mL ethylenediamine solvent to the reactant 2 S, fully stir evenly to obtain reactant suspension. The reactant mixture was transferred to a polytetrafluoroethylene-lined autoclave, heated to 120° C. under airtight conditions, and naturally cooled to room temperature after 12 hours of reaction. The collected product was washed with water and absolute ethanol respectively and dried at 60° C. for 10 h before use.

[0026] 2) Take 0.05g of cadmium sulfide graphene composite material powder, add 2.5ml of ethanol solution containing 0.0125g of binder polyethylene glycol (PEG20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com