Long-service life vacuum heat insulation ceramic-like decorative plate

A vacuum insulation and long-life technology, applied in layered products, buildings, synthetic resin layered products, etc., can solve the problems of high on-site management requirements, low thermal barrier ability, low combustion performance level, etc., to avoid human risks The effect of the construction cost, dimensional tolerance range and stability, and the diversity of construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

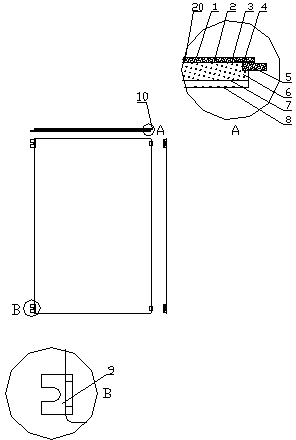

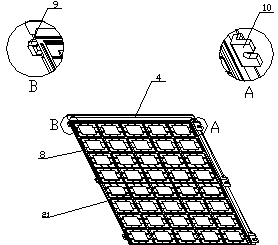

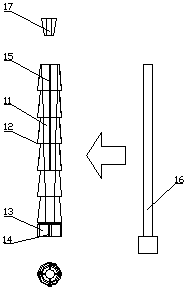

[0023]One of the preferred embodiments of the present invention is to take a cuboid vacuum heat-insulating ceramic decorative panel with a size of 600mm×400mm×15mm as an example, to manufacture a precision injection mold for inserts, and to pre-seal the three sides of the vacuum full-barrier membrane cavity / The bag side A (4) and the vacuum total barrier film cavity / bag side B (7) are placed between the parting surfaces of the mold, and non-flammable acrylonitrile (A), styrene (S) and acrylate ( A) The mixed material composed of ternary graft copolymer (ASA) thermosetting material a(2) and inorganic non-metallic material is injected into the vacuum full-barrier membrane cavity / bag A side (4) and the vacuum full-barrier membrane cavity / bag B between the surfaces (7) to obtain a thermosetting material a (2), one side forms a ceramic-like decorative surface (1), and the other side forms a ventilating installation surface (8). For the ventilation system, a layer of transparent fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com