Solid base carrier dilute metal element catalyst and preparation method

A metal element and solid base technology, which is applied in the field of solid base catalyst preparation, can solve the problems of complex antioxidant preparation process, equipment corrosion, environmental pollution, etc., achieve remarkable effects, improve stability, and expand specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

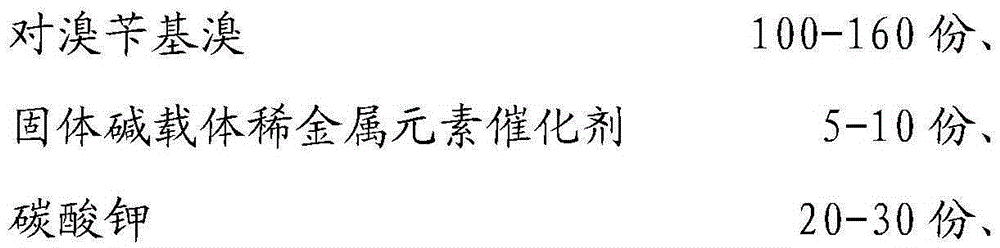

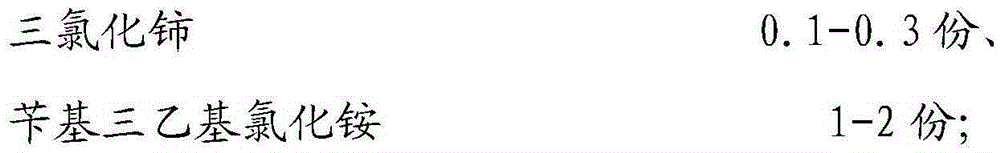

[0027] One, solid alkali carrier dilute metal element catalyst, prepared by the following steps;

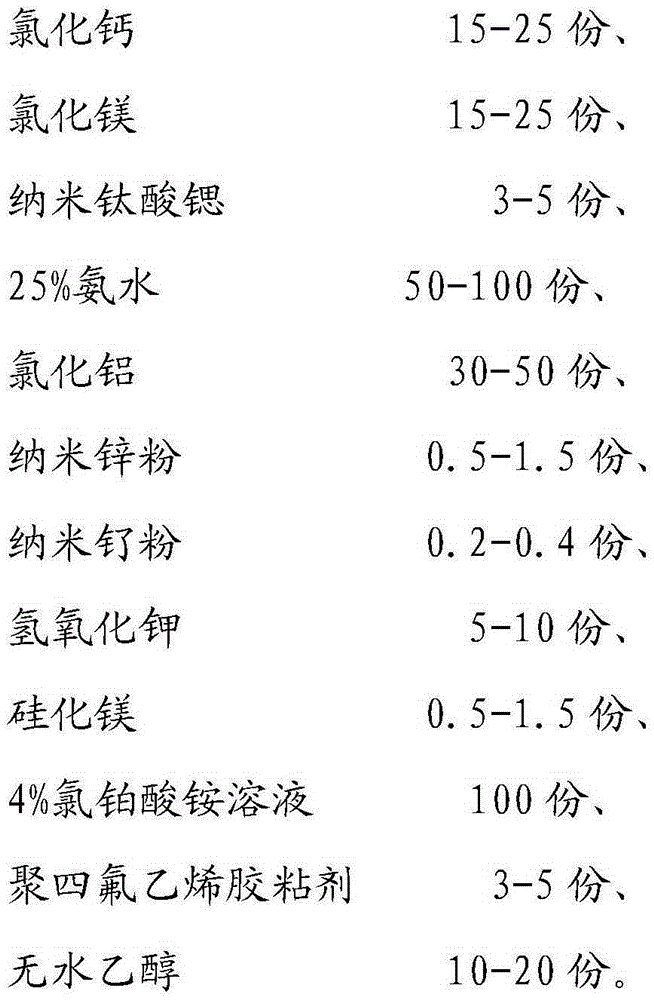

[0028] (a). Chemical composition: 750 parts of deionized water, 15 parts of calcium chloride, 25 parts of magnesium chloride, 3 parts of nano-strontium titanate, 100 parts of 25% ammonia water, 30 parts of aluminum chloride, 1.5 parts of nano-zinc powder, and nano-ruthenium 0.2 parts of powder, 10 parts of potassium hydroxide, 0.5 parts of magnesium silicide; 100 parts of 4% ammonium chloroplatinate solution; 5 parts of polytetrafluoroethylene adhesive, 20 parts of absolute ethanol;

[0029] (b). Dissolve calcium chloride, magnesium chloride, and aluminum chloride into 250 parts of deionized water, add 500 parts of deionized water into the reaction kettle, add nano-strontium titanate, nano-zinc powder, and nano-ruthenium powder, and start High-speed dispersing machine 1500 rpm / Dilute the ammonia water to 250 parts with deionized water, control the temperature of all the soluti...

Embodiment 2

[0037] One, solid alkali carrier dilute metal element catalyst, prepared by the following steps;

[0038] (a). Chemical composition: 750 parts of deionized water, 25 parts of calcium chloride, 15 parts of magnesium chloride, 5 parts of nano-strontium titanate, 50 parts of 25% ammonia water, 50 parts of aluminum chloride, 0.5 parts of nano-zinc powder, and nano-ruthenium 0.4 parts of powder, 5 parts of potassium hydroxide, 1.5 parts of magnesium silicide; 100 parts of 4% ammonium chloroplatinate solution; 3 parts of polytetrafluoroethylene adhesive, 10 parts of absolute ethanol;

[0039] (b). Dissolve calcium chloride, magnesium chloride, and aluminum chloride into 250 parts of deionized water, add 500 parts of deionized water into the reaction kettle, add nano-strontium titanate, nano-zinc powder, and nano-ruthenium powder, and start High-speed dispersing machine 2000 rpm / Dilute the ammonia water to 250 parts with deionized water, control the temperature of all the solutions...

Embodiment 3

[0047] One, solid alkali carrier dilute metal element catalyst, prepare by the following steps:

[0048] (a). Chemical composition: 750 parts of deionized water, 20 parts of calcium chloride, 20 parts of magnesium chloride, 4 parts of nano strontium titanate, 75 parts of 25% ammonia water, 45 parts of aluminum chloride, 1 part of nano zinc powder, nano 0.3 parts of ruthenium powder, 7.5 parts of potassium hydroxide, 1 part of magnesium silicide; 100 parts of 4% ammonium chloroplatinate solution; 4 parts of polytetrafluoroethylene adhesive, 15 parts of absolute ethanol;

[0049] (b). Dissolve calcium chloride, magnesium chloride, and aluminum chloride into 250 parts of deionized water, add 500 parts of deionized water into the reaction kettle, add nano-strontium titanate, nano-zinc powder, and nano-ruthenium powder, and start High speed dispersing machine 1750 rpm / Dilute the ammonia water to 250 parts with deionized water, control the temperature of all the solutions at 5°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com