Preparation methods of porous structured material selectively adsorbing and separating CO2 gas

An adsorption separation and selectivity technology, applied in separation methods, separation by adsorption, dispersed particles, etc., to achieve the effects of large output, high yield and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put zinc oxide (5mmol, 0.407g), 2-methylimidazole (20mmol, 1.642g), nickel acetate (5mmol, 2.448g) into the ball mill jar, then put stainless steel balls and add ethanol 1mL ball mill for 30 minutes , to obtain a green solid. The green solid was washed three times with 60 mL of methanol, and then dried at 60° C. for 12 hours to obtain a purple solid, which was named as ball-milled Zn / Ni-ZIF-8.

[0040] Ball-milled Zn / Ni-ZIF-8 was calcined in a tube furnace at 1000°C for 1 hour under a nitrogen atmosphere to obtain a black solid composite, which was recorded as ball-milled Zn / Ni-ZIF-8-1000, with a yield of 36%, namely Selective adsorption and separation of CO according to the present invention 2 Pore structure material of gas.

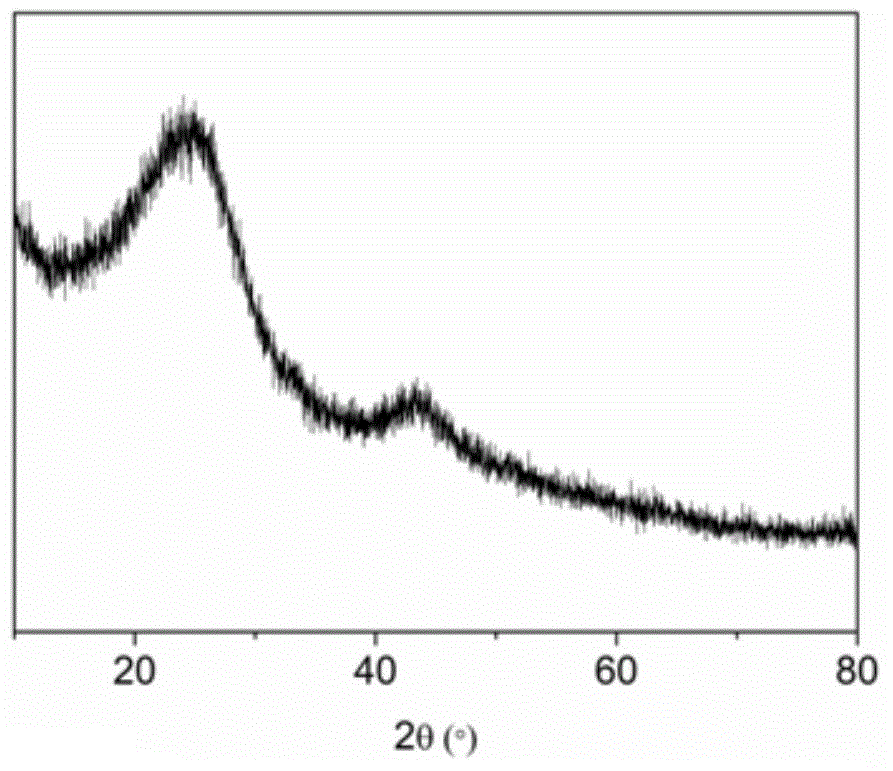

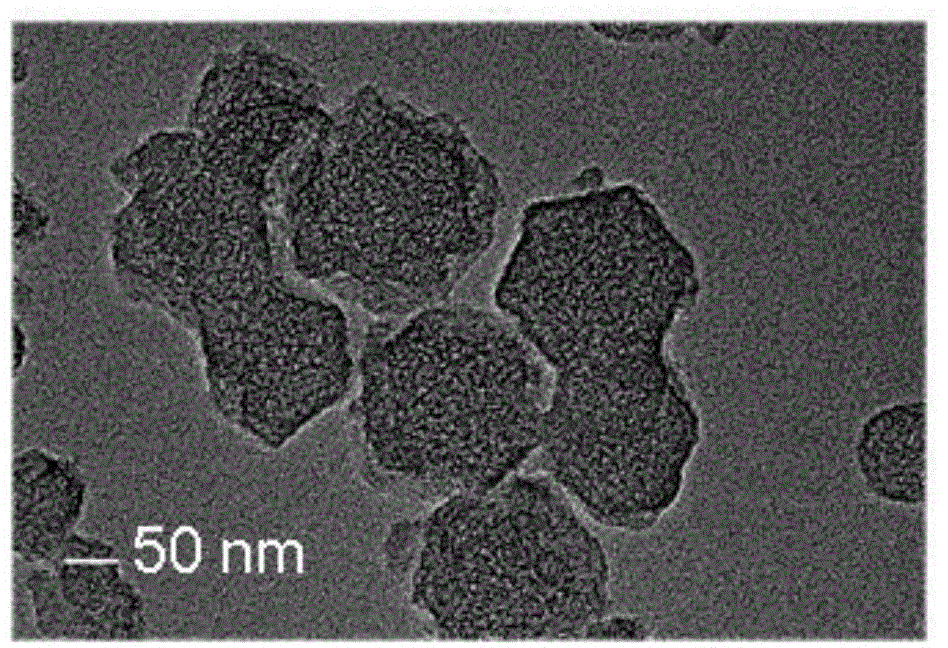

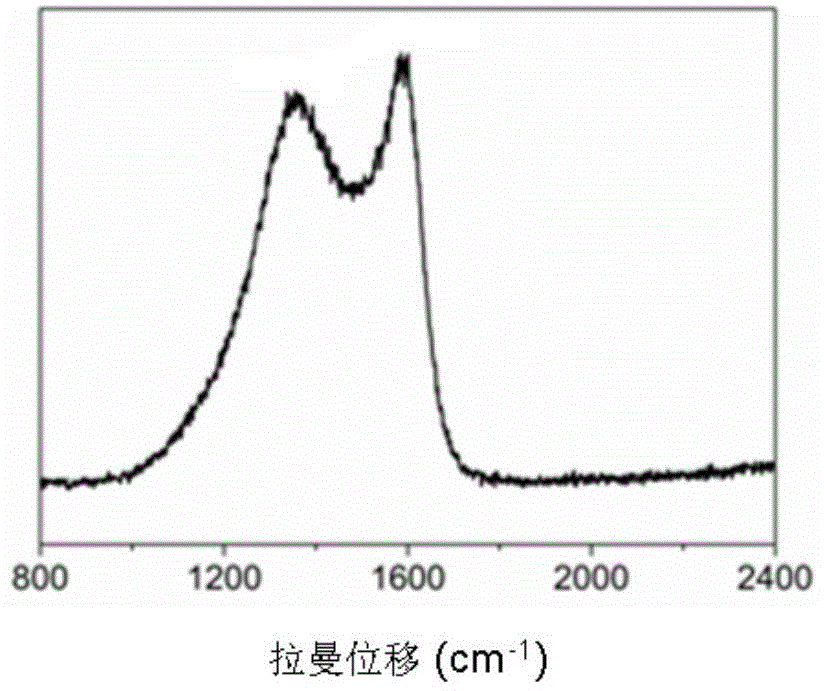

[0041] We carried out X-ray powder diffraction (PXRD) characterization, transmission electron microscopy (TEM) characterization, Raman characterization and X-ray photoelectron spectroscopy (XPS) analysis on the material. The gas adsorption c...

Embodiment 2

[0045] Put zinc oxide (4mmol, 0.3265g), 2-methylimidazole (20mmol, 1.642g), nickel acetate (4mmol, 1.9584g) into the ball mill jar, then put stainless steel balls and add ethanol 1mL ball mill for 20 minutes , to obtain a green solid. The green solid was washed three times with 60 mL of methanol, and then dried at 60° C. for 12 hours to obtain a purple solid, which was named as ball-milled Zn / Ni-ZIF-8.

[0046] Ball-milled Zn / Ni-ZIF-8 was calcined in a tube furnace at 900°C for 0.5 hours under a nitrogen atmosphere to obtain a black solid composite, which was called ball-milled Zn / Ni-ZIF-8-1000, with a yield of 35%, namely Selective adsorption and separation of CO according to the present invention 2 Pore structure material of gas.

[0047] We carried out X-ray powder diffraction (PXRD) characterization, transmission electron microscopy (TEM) characterization, Raman characterization and X-ray photoelectron spectroscopy (XPS) analysis on the material. The gas adsorption ca...

Embodiment 3

[0050] Put zinc oxide (3.33mmol, 0.271), 2-methylimidazole (20mmol, 1.642g), nickel acetate (6.66mmol, 3.2607g) into the ball mill jar, then put stainless steel balls and add 1mL ethanol ball mill for 50 minutes, a green solid was obtained. The green solid was washed three times with 60 mL of methanol, and then dried at 60° C. for 12 hours to obtain a purple solid, which was named as ball-milled Zn / Ni-ZIF-8.

[0051] The ball-milled Zn / Ni-ZIF-8 was calcined at 700°C for 3 hours in a nitrogen atmosphere in a tube furnace to obtain a black solid composite, which was recorded as ball-milled Zn / Ni-ZIF-8-1000, with a yield of 35.5%, namely Selective adsorption and separation of CO according to the present invention 2 Pore structure material of gas.

[0052] We carried out X-ray powder diffraction (PXRD) characterization, transmission electron microscopy (TEM) characterization, Raman characterization and X-ray photoelectron spectroscopy (XPS) analysis on the material. The gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com