A kind of solar photoelectric conversion coating and preparation method thereof

A photoelectric conversion and solar energy technology, applied in epoxy resin coatings, radiation-absorbing coatings, coatings, etc., can solve the problems of complex process, insufficient practicability, high production cost, etc., and achieve a wide range of applications, easy transportation and storage, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Grinding 30 parts by weight of gallium arsenide and 30 parts by weight of graphene to make the particle size reach 10 μm.

[0039] 2) Treat 30 parts by weight of gallium arsenide described in step 1) with 1 part by weight of silane coupling agent to make the surface hydrophilic, so that its HLB value is 15.

[0040] 3) 30 parts by weight of gallium arsenide, 30 parts by weight of graphene, 25 parts by weight of glycerol epoxy resin, 10 parts by weight of polyoxyethylene alkyl ether and 5 parts by weight of polyamide described in step 2) Add it into a high-pressure homogenizer for dispersion treatment to obtain a paint emulsion with uniform dispersion of components.

[0041] 4) Immediately spray-dry the coating emulsion after dispersion treatment described in step 3) with a spray dryer, and obtain solar photoelectric conversion coating powder after drying.

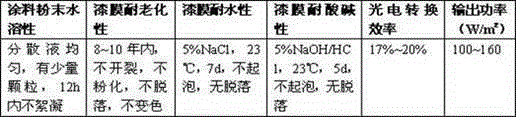

[0042]The powder coating prepared by the present invention is dissolved in a water solvent, stirred evenly wit...

Embodiment 2

[0044] 1) Grinding 40 parts by weight of fullerene and 40 parts by weight of graphene to make the particle size reach 10 μm.

[0045] 2) The surface of 40 parts by weight of fullerene described in step 1) is treated with 1.5 parts by weight of silane coupling agent to make its HLB value 17.

[0046] 3) 40 parts by weight of fullerene, 40 parts by weight of graphene, 30 parts by weight of hydantoin epoxy resin, 10 parts by weight of polyoxyethylene alkyl ester and 6 parts by weight of polyoxyethylene alkyl ester described in step 2) The carbamate is added into a high-pressure homogenizer for dispersion treatment to obtain a paint emulsion with uniform dispersion of components.

[0047] 4) Immediately spray-dry the coating emulsion after dispersion treatment described in step 3) with a spray dryer, and obtain solar photoelectric conversion coating powder after drying.

[0048] The powder coating prepared by the present invention is dissolved in a water solvent, stirred evenly w...

Embodiment 3

[0050] 1) Grinding 45 parts by weight of antimony-containing silicon crystals and 45 parts by weight of graphene to make the particle size reach 10 μm.

[0051] 2) The surface of 45 parts by weight of the antimony-containing silicon crystal described in step 1) is treated with 2 parts by weight of silane coupling agent to make the HLB value 16.

[0052] 3) 45 parts by weight of antimony-containing silicon crystals described in step 2), 45 parts by weight of graphene and 27 parts by weight of E-51 epoxy resin, 8 parts by weight of polyoxyethylene aryl ether and 5 parts by weight The ethyl acrylate is added into a high-pressure homogenizer for dispersion treatment to obtain a paint emulsion in which each component is uniformly dispersed.

[0053] 4) Immediately spray-dry the coating emulsion after dispersion treatment described in step 3) with a spray dryer, and obtain solar photoelectric conversion coating powder after drying.

[0054] The powder paint prepared by the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com