Method for preparing intracellular lactase powder by spray drying process of breaking cell walls of lactic acid bacteria

A technology of spray drying and lactase powder, which is applied in the field of enzyme preparation, can solve the problems of high cost, complicated operation, loss of enzyme activity, etc., and achieve the effects of low production cost, simple operation and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using the chemical method to break the wall to treat the fermentation broth, the steps and instructions are as follows:

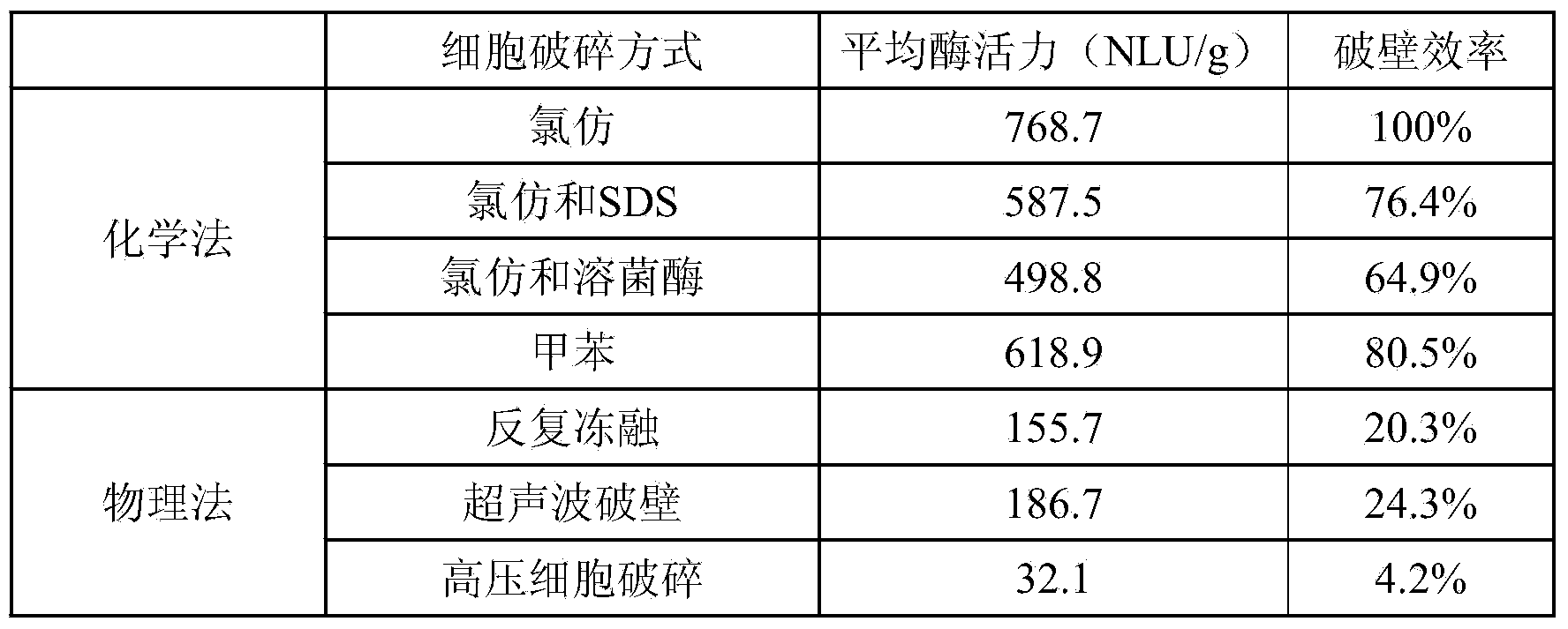

[0038] Different cell disruption methods were used to treat the Lactobacillus reuteri fermentation broth, and the lactase activity was determined. The results are shown in Table 1. The efficiency of chemical method to disrupt cells is significantly higher than that of physical method, among which only adding chloroform has the best cell disruption effect, and the enzyme activity is the highest, which can reach 768.7NLU / g. The enzyme activity measured after the cells were disrupted by physical methods was low, indicating that the cells were not fully disrupted and the lactase could not be fully released. Taking the crude enzyme activity after wall breaking with chloroform as 100%, the wall breaking efficiencies of other methods were calculated, and the results are shown in Table 1. The high-pressure cell disruption method had the worst efficiency at 4....

Embodiment 2

[0044] A method for preparing intracellular lactase powder by crushing the cell walls of lactic acid bacteria by a spray drying method, the steps are as follows:

[0045] Add protective agents directly to the fermentation broth, such as dextrin and skimmed milk powder, which can be added separately or mixed. Set the spray dryer operating parameters such as inlet air temperature and material flow rate. The power of different spray drying equipment (laboratory) is different, and the recovery efficiency of enzyme activity is different. For example, SP-1500 experimental spray dryer (Shanghai Shunyi Technology Co., Ltd.), set the air inlet at about 125°C, the material flow rate at about 400mL / h, add skimmed milk powder and dextrin to the fermentation broth at the same time, the ratio is 7: 1. A total of 15% was added, and the recovery rate of enzyme activity was more than 80%.

[0046] In this method, the cells of lactic acid bacteria are swelled and broken by instantaneously inc...

Embodiment 3

[0050] A method for preparing intracellular lactase powder by crushing the cell walls of lactic acid bacteria by a spray drying method, the steps are as follows:

[0051] Add protective agent dextrin directly to the fermentation broth, add 15% dextrin, g / 100mL, set the operating parameters of the spray dryer, the inlet air temperature and material flow rate are 125°C, the material flow rate is 400mL / h, and spray dry to obtain lactase powder .

[0052] Other parts that need to be explained are as follows:

[0053] Fermentation is carried out with the strain MF2-2 as the starting strain, and lactic acid bacteria cells containing lactase are obtained. Further, by breaking the bacterium cell wall through chemical and physical methods in the present invention, a high-activity lactase crude enzyme liquid is obtained, but the crude enzyme liquid is unstable and easily inactivated. The present invention utilizes the spray drying method to directly prepare the lactase preparation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com