Method for grafting modified aramid fiber on surface of graphene oxide

A graphene surface and aramid fiber technology, which is applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve the problems of reducing the performance of composite materials, poor wettability of aramid fibers, and poor interfacial adhesion of composite materials, etc. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is carried out in the following manner:

[0025] 1. Preparation of aminated graphene oxide

[0026] Graphene oxide was prepared by the improved Hummer method, and the prepared graphene oxide was added to the aqueous solution, and ultrasonically treated for 30~60min to prepare a 1g / L graphene oxide suspension, adding 10ml of ethylenediamine, at 40°C, mechanically Stir and react for 24 hours, wash and dry to prepare aminated graphene oxide.

[0027] 2. Dopamine modified aramid fiber

[0028] Extract the aramid fiber with acetone for 24 hours, remove the sizing agent on its surface, wash, dry and set aside. Prepare a Tris-HCl buffer solution with pH=8.5, add dopamine hydrochloride, prepare a dopamine solution with a concentration of 2g / L, add aramid fibers into the dopamine solution, soak for 24 hours, wash with deionized water, and dry to obtain dopamine modified permanent aramid fiber.

[0029] 3. Grafting modified aramid fibers on the surface of grap...

Embodiment 2

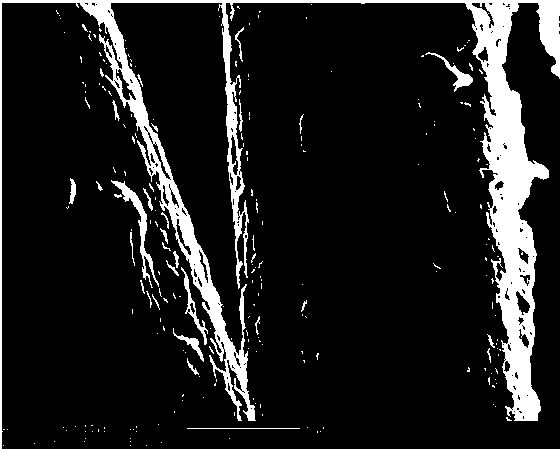

[0032] The difference between this example and Example 1 is that the reaction temperature in step one is 60°C. The scanning electron microscope pictures of the aramid fibers grafted and modified on the surface of graphene oxide obtained in this embodiment are as follows: image 3 and 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com