Organic ultraviolet light detector taking HATCN and Cu (I) complex prepared by HATCN as anode buffer layer

A technology of anode buffer layer and organic ultraviolet light, which is applied in the direction of electric solid device, semiconductor device, semiconductor/solid device manufacturing, etc., to achieve the effect of facilitating hole transport, preventing device aging, and high electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

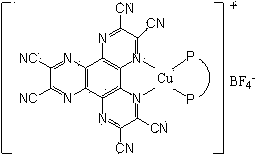

[0052] ②. Preparation of Cu(I) complex Ⅰ (preparation of Cu(I) complex CuDH):

[0053] With 538.6mg (1.0mmol) two (2-diphenylphosphino) phenyl ether, 314.0mg (1.0mmol) [Cu (CH 3 EN) 4 ] BF 4 Dissolve in 10ml of dichloromethane, stir at room temperature for about 30 minutes, then add 384.3mg (1.0mmol) HATCN, and continue stirring for one hour. The final solution was rotary evaporated, and the obtained solid powder was CuDH.

[0054] ③. Preparation of Cu(I) complex II (preparation of Cu(I) complex CuBH):

[0055] With 446.5mg (1.0mmol) 1,2-bis (diphenylphosphino) benzene, 314.0mg (1.0mmol) [Cu (CH 3 EN) 4 ] BF 4 Dissolve in 10ml of dichloromethane, stir at room temperature for about 30 minutes, then add 384.3mg (1.0mmol) HATCN, and continue stirring for one hour. The final solution was rotary evaporated, and the obtained solid powder was CuBH.

Embodiment 1

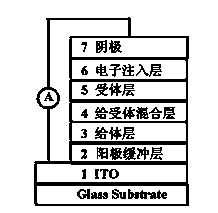

[0057] select figure 1 The device structure shown, in the present embodiment, first on the ITO anode 1, the anode buffer layer HATCN with a thickness of 7nm is vacuum-deposited, then on the anode buffer layer 2, an electron donor layer 3 of 30nm is deposited, and then on the electron donor A mixed layer 4 of electron donor and electron acceptor with a weight ratio of 1:1 and a thickness of 40 nm is deposited on layer 3, and then a 40 nm electron acceptor layer 5 is deposited on the mixed layer 4, followed by a 1 nm electron injection layer 6 , and finally deposited a 200nm metallic Al cathode. All the above films are deposited by vacuum coating process, the thickness of the film is monitored by a film thickness monitor, and the external circuit is detected by KEITHLEY2601.

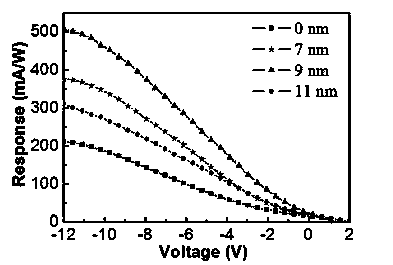

[0058] Effect: at a light intensity of 1.05mW / cm 2 , Under the irradiation of ultraviolet light with a center wavelength of 365nm and an external reverse bias of -12V, the photocurrent response value of ...

Embodiment 2

[0060] On the basis of Example 1, the thickness of the anode buffer layer 2 was changed to 9 nm, and other manufacturing conditions remained unchanged.

[0061] Effect: at light intensity 1.05mW / cm 2 , Under the irradiation of light with a central wavelength of 365nm and an external reverse bias of -12V, the photocurrent response value of the device is 508mA / W (see figure 2 ), the current density is 0.53mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com