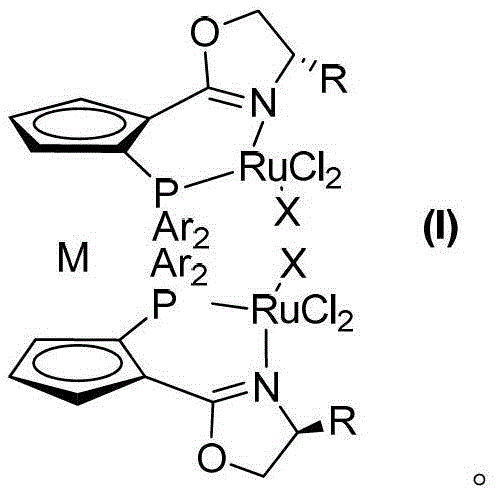

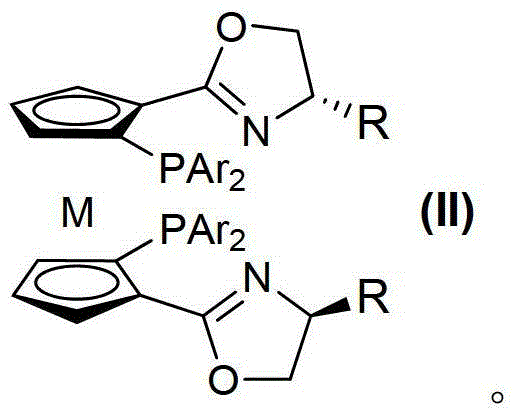

Planar chiral double-reactive center ruthenium catalyst and synthesis and application thereof

A ruthenium catalyst and dual-reaction technology, which are applied to the ruthenium catalyst and its synthesis and application, the chiral double-reaction center ruthenium catalyst and its synthesis, and the application fields of asymmetric hydrogenation of β-aminoketone compounds, which can solve the problem of catalysts. Ligand synthesis is complex, it cannot be stably stored, and the cost of metal rhodium is high. It achieves good industrial application prospects, convenient storage and use, and good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Synthesis of Hilarochiral Double Reaction Center Ruthenium Catalysts

[0060] Tris(triphenylphosphine)ruthenium dichloride (3.8 mg, 4 μmol) and chiral ligand (M=Ru, R=i-Pr, Ar=4-MeC 6 h 4 -, 2 μmol) was dissolved in methanol (3 mL), heated and stirred at 0°C for 1 hour. Cool to room temperature, remove the solvent under reduced pressure, and separate by column chromatography (using a silica gel column, eluent: ethyl acetate / petroleum ether = 1 / 5) to obtain 3.21 mg of a dark green solid with a yield of 92%.

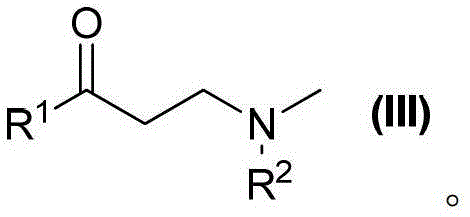

[0061] Preparation of 3-benzylmethylamino-1-phenylpropanol from 3-benzylmethylamino-1-propiophenone

[0062]

[0063] Under nitrogen atmosphere, 3-benzylmethylamino-1-propiophenone (0.4mmol), methanol (2.6mL), potassium hydroxide in methanol (0.4mL, 0.08M) and catalyst 1.73mg (TON=400) were added. The reaction system was placed in an autoclave at 25 °C and H 2 (20atm) and stirred for 6 hours. The solvent was removed under reduced pressure, separated by colum...

Embodiment 2

[0065] Synthesis of Hilarochiral Double Reaction Center Ruthenium Catalysts

[0066] Tris(triphenylphosphine)ruthenium dichloride (3.8 mg, 4 μmmol) and chiral ligands (M=Ru, R=s-Bu, Ar=C 6 h 5 -, 2.8 μmmol) was dissolved in ethanol (3 mL), heated and stirred at 30°C for 2 hours. Cool to room temperature, remove the solvent under reduced pressure, and separate by column chromatography (using a silica gel column, eluent: ethyl acetate / petroleum ether = 1 / 5) to obtain 3.31 mg of a dark green solid with a yield of 94.8%.

[0067] Preparation of 3-benzylmethylamino-1-phenylpropanol from 3-benzylmethylamino-1-propiophenone

[0068]

[0069] Under nitrogen atmosphere, 3-benzylmethylamino-1-propiophenone (0.4mmol), ethanol (2.6mL), potassium hydroxide in ethanol (0.4mL, 0.09M) and catalyst 1.715mg (TON=400) were added. The reaction system was placed in an autoclave at 25 °C and H 2 (20atm) and stirred for 12 hours. The solvent was removed under reduced pressure, separated by col...

Embodiment 3

[0071] Synthesis of Hilarochiral Double Reaction Center Ruthenium Catalysts

[0072] Tris(triphenylphosphine)ruthenium dichloride (3.8 mg, 4 μmmol) and chiral ligand (M=Ru, R=Me, Ar=3,5-(CF 3 ) 2 C 6 h 3 -, 2.2 μmmol) was dissolved in toluene (3 mL), heated and stirred at 100°C for 2 hours. Cool to room temperature, remove the solvent under reduced pressure, and separate by column chromatography (using a silica gel column, eluent: ethyl acetate / petroleum ether=1 / 5) to obtain 3.56 mg of a dark green solid with a yield of 96.1%.

[0073] Preparation of 3-benzylmethylamino-1-phenylpropanol from 3-benzylmethylamino-1-propiophenone

[0074]

[0075] Under nitrogen atmosphere, 3-benzylmethylamino-1-propiophenone (0.4mmol), toluene (2.6mL), potassium hydroxide aqueous solution (0.4mL, 0.1M) and catalyst 1.715mg (TON=400) were added. The reaction system was placed in an autoclave at 10 °C and H 2 (20atm) and stirred for 12 hours. The solvent was removed under reduced pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com