Biological adhesive microsphere with nuclear shell structure and preparation method of microsphere

A technology of bioadhesion and core-shell structure, applied in the field of medicine, can solve the problem of low eradication rate of Helicobacter pylori, achieve the effect of reducing drug loss and good mucosal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

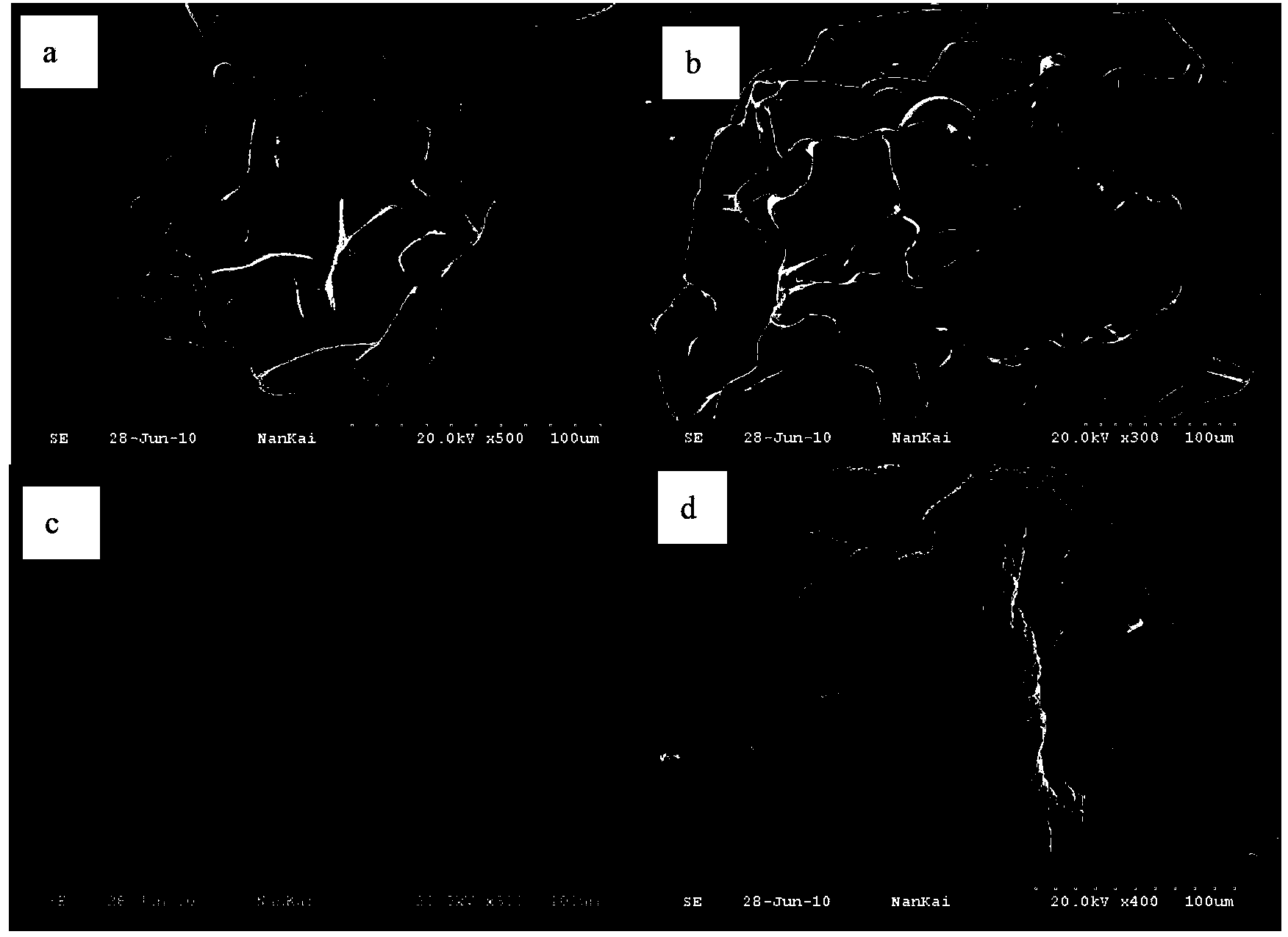

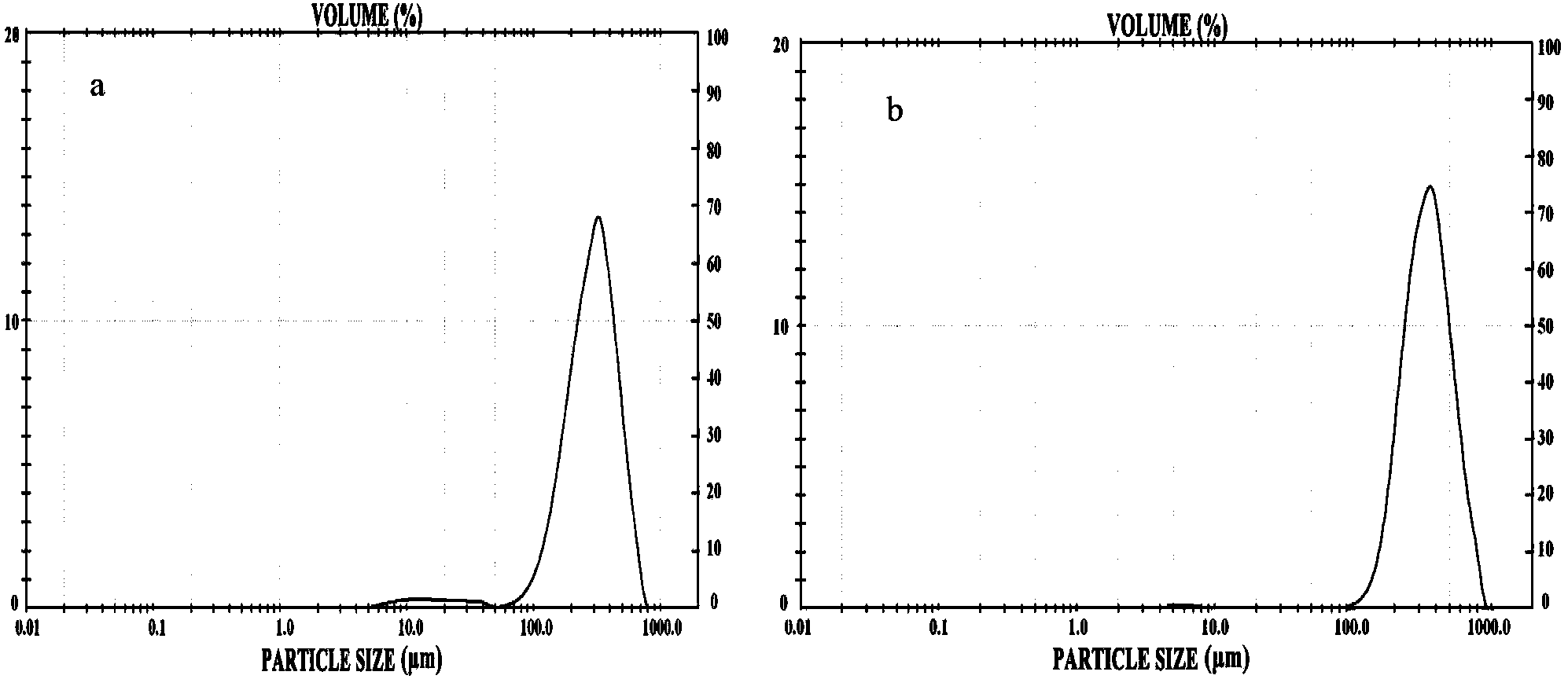

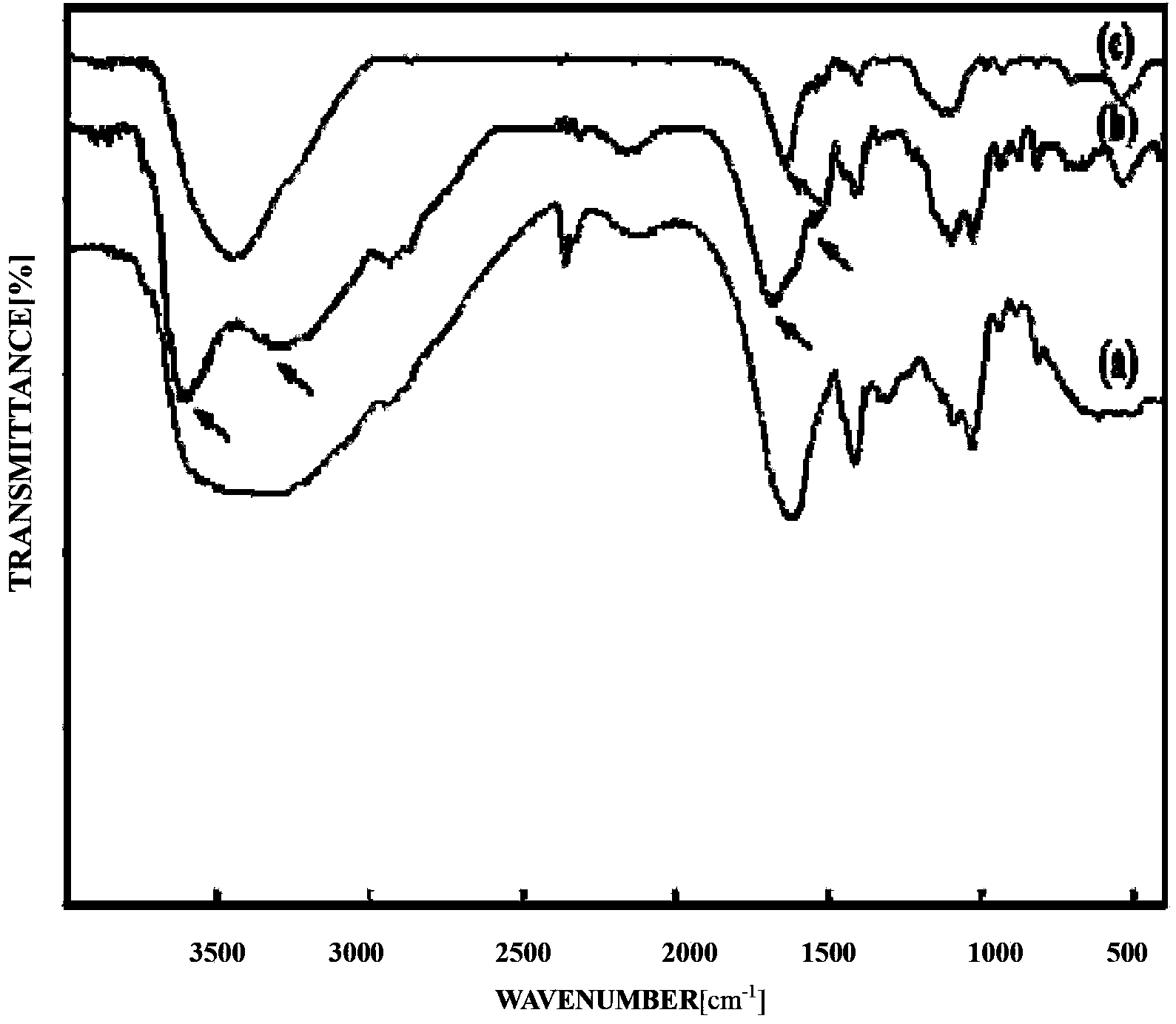

Method used

Image

Examples

Embodiment 1

[0079] 1. Preparation of alkaloid ethanol solution

[0080] 1) Crush the raw materials Coptis chinensis and Evodia rutaecarpa, add them to an ethanol solution with a concentration of 60-75% by mass, heat and reflux for extraction 3-5 times, each time for 1.5-2 hours, wherein the weight ratio of Coptis chinensis and Evodia rutaecarpa is 6:1 , the ratio of the total weight of Coptidis Rhizoma and Evodia Fructus to the total volume of ethanol solution in each extraction process is 1:8-12 (g / ml or kg / L), that is, adding ethanol solution 8 -12ml or add 8-12L of ethanol solution to every 1kg of Coptis rhizome and Evodia rutaecarpa mixed raw materials;

[0081] 2) Combine the reflux extracts, concentrate into an extract with a relative density of 1.10-1.30, then place the extract in a freeze dryer (Savant Modulyo D freeze dryer, Thermo company, U.S.) to freeze-dry to constant weight, The total alkaloid extract was obtained.

[0082] In the present invention, besides 6:1, the weight...

Embodiment 2

[0144] 1. In the process of preparing the microsphere core, except that it is different as described below, all the other are the same as in Example 1, specifically as follows:

[0145] 1) The volume ratio of emulsifier Span80 and Tween80 in the mixed emulsion preparation step is 3:1; the ratio of the total volume of emulsifier Span80 and Tween80 to the volume of liquid paraffin is 1:90; the stirring temperature is 50°C;

[0146] 2) The weight ratio of gelatin and sodium alginate in the first carrier solution preparation step is 6:4, and the ratio of the total weight of gelatin and sodium alginate to the volume of the aqueous solution is 10:100 (g / ml), that is, every 100ml The total weight of gelatin and sodium alginate added in the water is 10g;

[0147] 3) In the emulsification treatment step:

[0148] The temperature of the first emulsification treatment is 35°C, the stirring speed is 500rpm, the drop rate of the gelatin-sodium alginate aqueous solution into the mixed emul...

Embodiment 3

[0161] 1. In the process of preparing the microsphere core, except that it is different as described below, all the other are the same as in Example 1, specifically as follows:

[0162] 1) The volume ratio of emulsifier Span80 and Tween80 in the mixed emulsion preparation step is 5:1; the ratio of the total volume of emulsifier Span80 and Tween80 to the volume of liquid paraffin is 1:110; the stirring temperature is 40°C;

[0163] 2) The weight ratio of gelatin and sodium alginate in the first carrier solution preparation step is 8:2, and the ratio of the total weight of gelatin and sodium alginate to the volume of the aqueous solution is 5:100 (g / ml), that is, every 100ml The total weight of the gelatin and sodium alginate added in the water is 5g;

[0164] 3) In the emulsification treatment step

[0165] The temperature of the first emulsification treatment is 55°C, the stirring speed is 300rpm, and the gelatin-sodium alginate aqueous solution is dripped

[0166] The rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com