Waterborne polyurethane emulsion and preparation method thereof

A water-based polyurethane and emulsion technology, which is applied in the field of polymer materials to achieve good flame retardant performance, strong chemical stability, and good water and solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

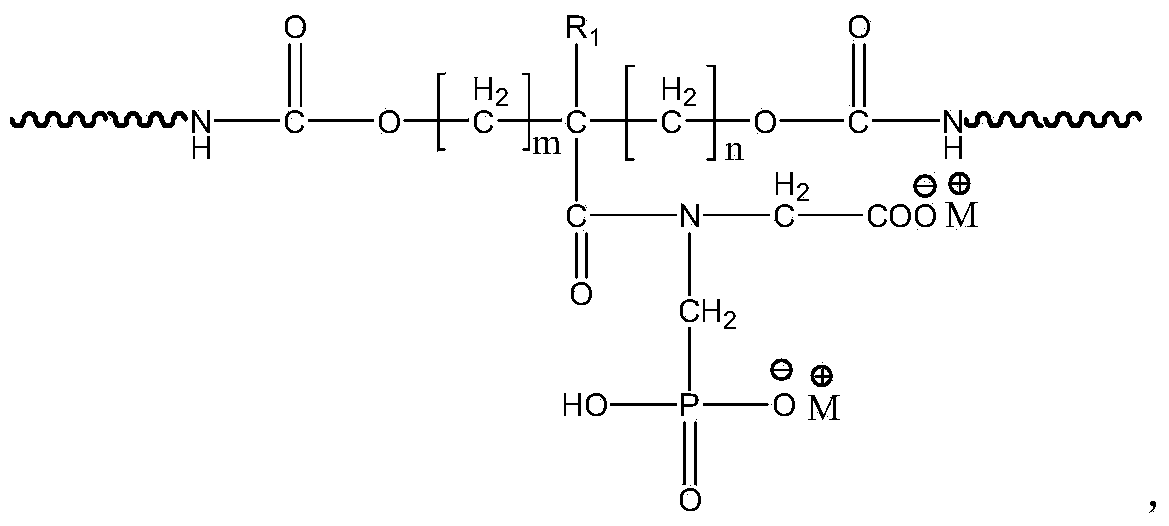

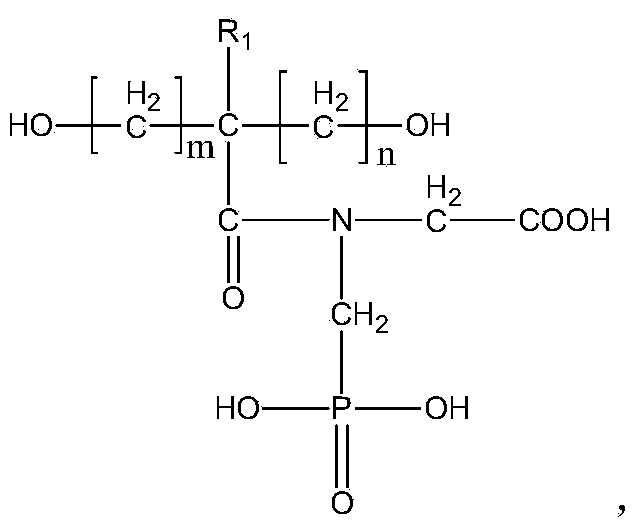

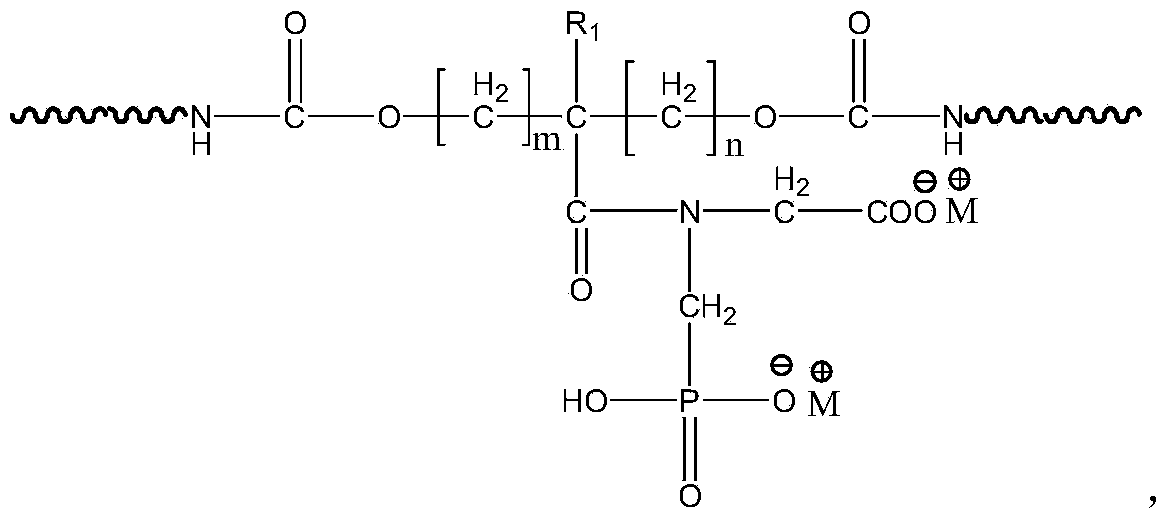

Image

Examples

preparation example Construction

[0047] The present invention also provides a kind of preparation method of aqueous polyurethane emulsion, comprises the following steps:

[0048] (1) Dehydrating the oligomer polyol and the small molecule chain extender until the moisture content of the oligomer polyol and the small molecule chain extender is 0.05%;

[0049] (2) Mix the oligomer polyol and the small molecule chain extender after dehydration in step (1) with the diisocyanate, add a solvent, carry out at 60-85°C, measure the reaction system during the reaction NCO content;

[0050] (3) After the NCO content is stable, add the hydrophilic chain extender and catalyst, and react under the condition that the viscosity of the reaction system does not exceed 5000MPas, and measure the NCO content of the reaction system during the reaction;

[0051] (4) When the NCO content is stable, cool to 45-50° C., add the salt-forming reagent, and carry out neutralization reaction to obtain a water-based polyurethane prepolymer;

...

Embodiment 1

[0062] Step 1: 50 g of polytetrahydrofuran ether diol with a molecular weight of 2000, 50 g of polybutylene adipate diol with a molecular weight of 2000, 2 g of neopentyl glycol, and 2 g of trimethylol propane were vacuumized at 100 ° C Dehydration for 1h, the vacuum degree is -0.08~-0.1mPa, so that the moisture content is less than 0.05%; because the oligomer polyol or small molecule chain extender may absorb moisture in the air during storage, the water will interact with the polyisocyanate reaction, resulting in a gel, so it is very necessary to dehydrate them before use.

[0063] Step 2: Put the diol mixture obtained in Step 1 into the reaction kettle, add 40g of isophorone diisocyanate at 80°C, and measure the NCO content in the system by the di-n-butylamine method every half hour. After 2 hours of reaction, the content of NCO reached a stable level and did not change;

[0064] Step 3: Lower the temperature of the reaction system to 75°C, add 18g of hydrophilic chain ext...

Embodiment 2

[0073] Step 1: Vacuumize and dehydrate 120 g of polytetrahydrofuran ether diol with a molecular weight of 2000 at 100°C for 1 hour, and the degree of vacuum is -0.08~-0.1mPa, so that the moisture content is less than 0.05%;

[0074] Step 2: Put the diol obtained in step: 1 into the reaction kettle, add 40g of isophorone diisocyanate and 7.5g of hexamethylene diisocyanate at 85°C, and use diisocyanate every half hour The NCO content in the system is measured by the butylamine method. After 2 hours of reaction, the NCO content reaches a stable level and does not change;

[0075] Step 3: Lower the temperature of the system by 75°C, add 21.96g of hydrophilic chain extender and 0.1ml of organic bismuth catalyst, measure the NCO content in the system with the di-n-butylamine method every half hour, and react for 1 hour, the system If the viscosity is too high, add 40g butanone to continue the reaction. After 3 hours of reaction, the content of NCO becomes stable and does not change;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com