Absorbable magnesium alloy staple having antibiosis and anti-inflammation functions, and making method thereof

An antibacterial, anti-inflammatory, and magnesium alloy technology, which is applied in medical science, surgery, surgical instruments, etc., can solve the problems of peeling, tissue hyperplasia, poor bonding force between gelatin and magnesium alloy, etc., and achieve the effect of increasing the load capacity and slowing down the degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

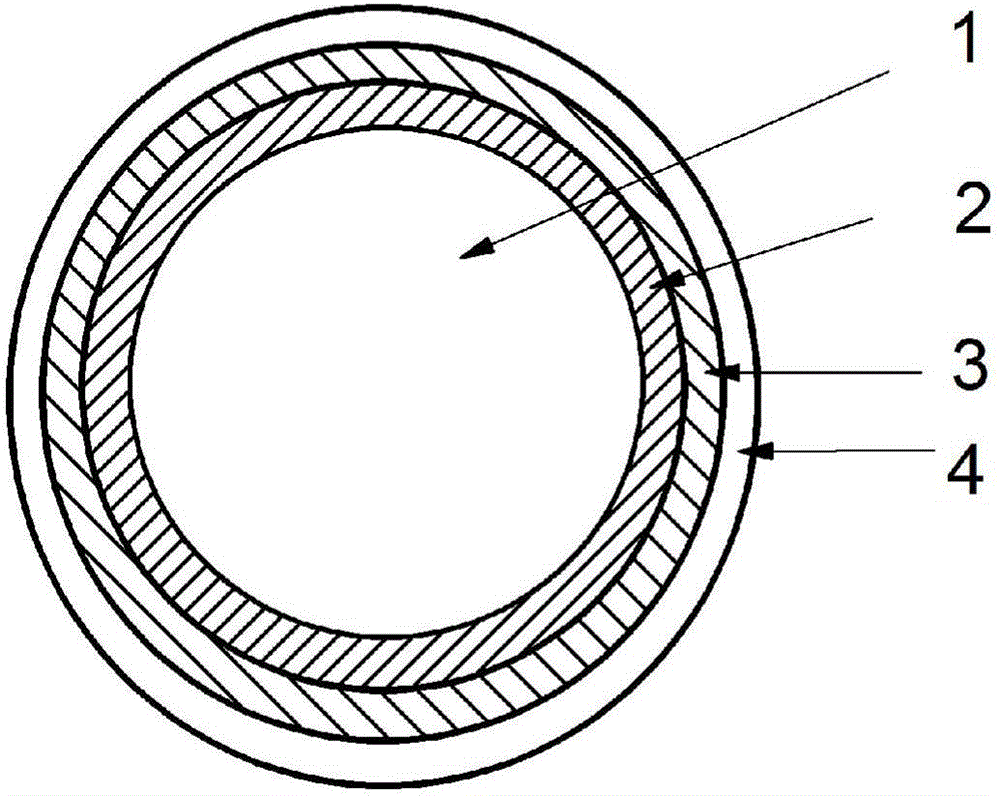

[0030] The absorbable magnesium alloy staple with antibacterial and anti-inflammatory functions of the present invention consists of a core of pure magnesium wire with a porous ceramic layer on the surface, an intermediate layer loaded with ibuprofen anti-inflammatory drugs and copper ions with gelatin as a carrier, and is degradable. The composition of the outer surface layer of polylactic acid, its specific preparation process is as follows:

[0031] 1) Drawing pure magnesium into a wire with a diameter of 0.3mm;

[0032] 2) Perform micro-arc oxidation treatment on the magnesium wire. The main components of the electrolyte are 10g / L sodium silicate, 2g / LNaOH and 8g / L hydroxyapatite nanoparticles, the magnesium wire is immersed in it, and a voltage of 420V is applied for 15 minutes of micro-arc oxidation treatment to make it A layer of porous ceramic layer rich in magnesium oxide, magnesium silicate and hydroxyapatite is formed in situ on the surface. The average micropore s...

Embodiment 2

[0040] Absorbable magnesium alloy staples with antibacterial and anti-inflammatory functions are composed of an AZ31B magnesium alloy wire core with a porous ceramic layer on the surface, a middle layer loaded with nabumetone and copper ions on the gelatin carrier, and an outer surface of degradable polylactic acid. Layer composition, the specific preparation process is as follows:

[0041] 1) AZ31B magnesium alloy is drawn into a wire with a diameter of 0.5mm;

[0042] 2) Phosphating the surface of the magnesium alloy wire, the solution is NH 4 h 2 PO 4 120g / L, (NH 4 ) 2 SO 3 ·H 2 O30g / L, ammoniacal liquor (30%) 6mL / L, generate the porous ceramic layer based on the phosphate of magnesium, the average pore size of ceramic layer is 10 μ m, and average layer thickness is 30 μ m;

[0043] 3) Weigh 5mg of nabumetone and dissolve it in 100ml of dichloromethane solution;

[0044] 4) Dissolve 3g of gelatin in 1L of 80°C distilled water to obtain a gelatin solution, add an app...

Embodiment 3

[0050] The absorbable magnesium alloy staple with antibacterial and anti-inflammatory functions consists of a WE43 magnesium alloy wire core with a porous ceramic layer on the surface, a middle layer loaded with acemetacin and copper ions on the gelatin carrier, and a degradable PLGA surface. Surface composition, its specific preparation process is as follows:

[0051] 1) Drawing WE43 magnesium alloy into a wire with a diameter of 0.5mm;

[0052] 2) Perform micro-arc oxidation treatment on the magnesium wire. The main components of the electrolyte are 10g / L sodium silicate and 2g / LNaOH. The magnesium wire is immersed in it, and a voltage of 380V is applied for 10 minutes of micro-arc oxidation treatment, so that a layer rich in magnesium oxide is formed on the surface in situ. , Magnesium silicate porous ceramic layer, the average micropore size of the ceramic layer is 8 μm, and the average layer thickness is 20 μm;

[0053] 3) Weigh 10 mg of acemetacin and dissolve it in 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com