Method for synthesizing ternary-copolymerized super-absorbent resin

A technology of superabsorbent resin and synthesis method, which is applied in the field of superabsorbent resin, can solve the problems of increasing process cost, secondary pollution, and reducing product purity, and achieve the effects of reducing process cost, increasing reaction rate, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

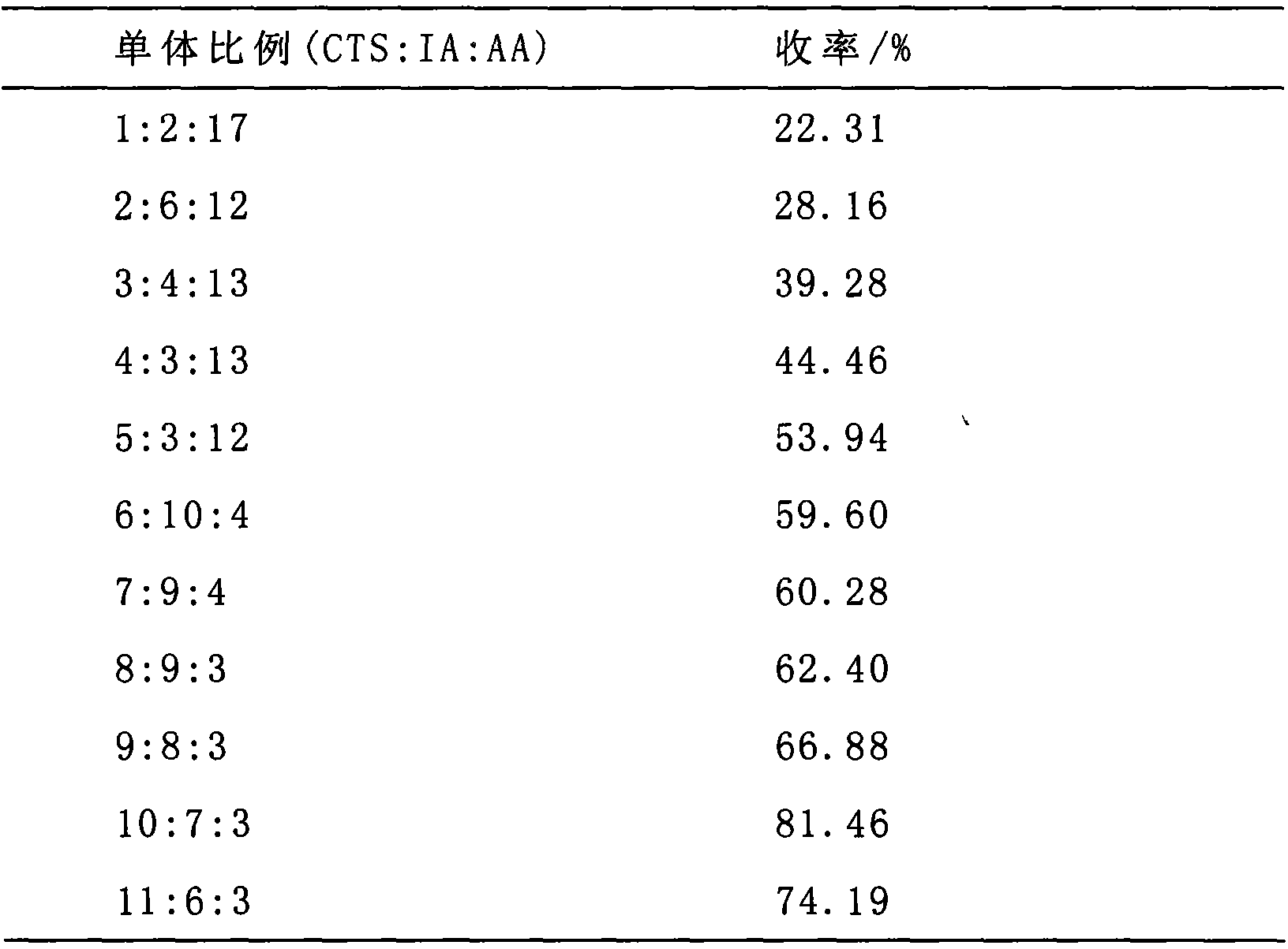

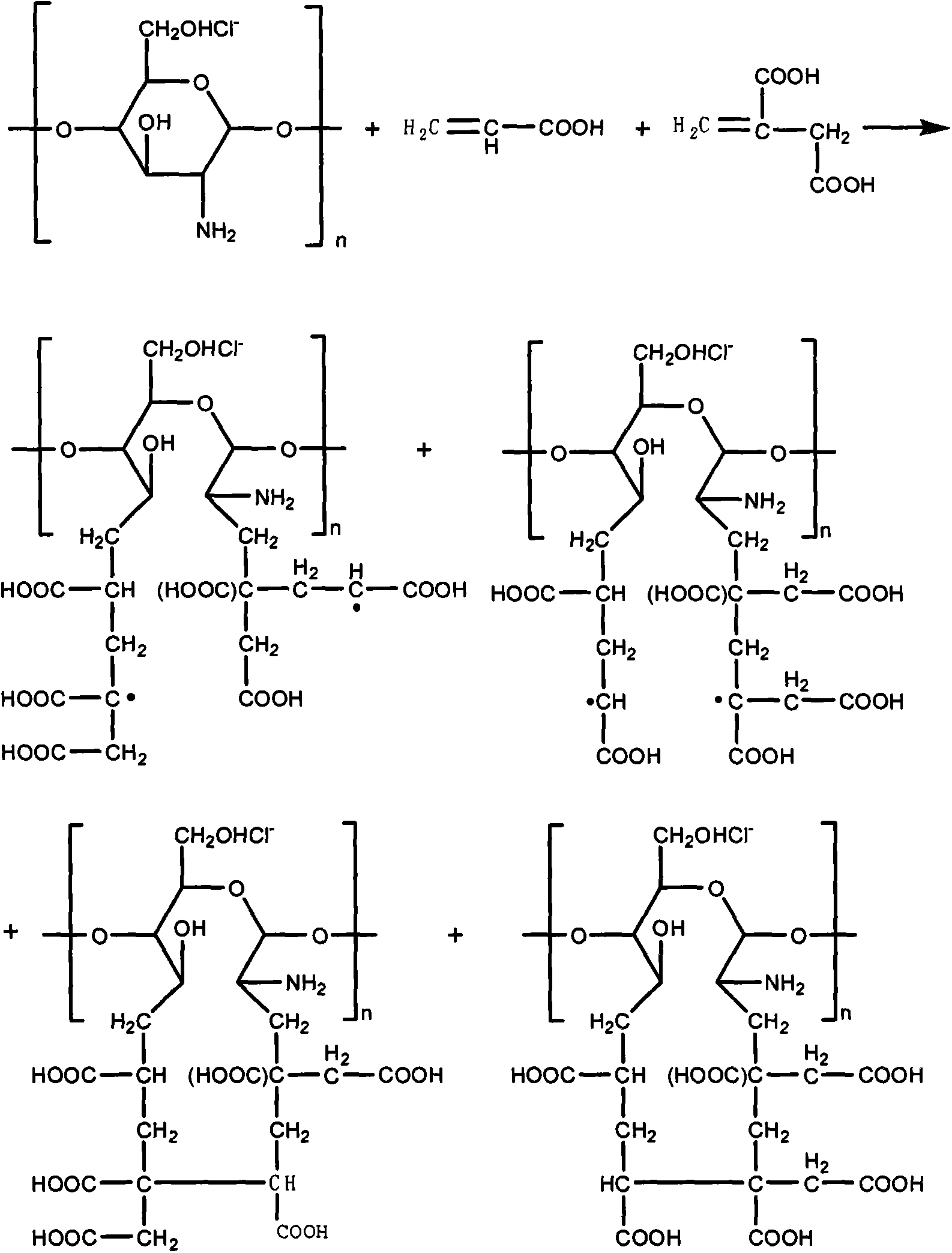

Embodiment 1

[0034] Chitosan hydrochloride 10g, itaconic acid 7g, stirred and dissolved in 80mL distilled water, after reaching 40°C, three kinds of initiators, ammonium persulfate-sodium bisulfite, ammonium persulfate and cerium ammonium nitrate were added respectively, and parallel Test, the concentration is 15%. Under nitrogen protection, 20 mL of acrylic acid cross-linking agent with a concentration of 15% was added through a dropping funnel, and reacted for 6 h. The yield of ammonium persulfate-sodium bisulfite was 87.6%, the yield of ammonium persulfate was 49.6%, and the yield of ammonium cerium nitrate was 9.6%.

Embodiment 2

[0036] Ammonium persulfate-sodium bisulfite is selected as the initiator, the preferred concentration range is 1%-18%, and other conditions are as in Example 1. The product yield increases gradually. When the concentration is 1-5%, there is almost no reaction between the monomers. When the concentration is 10%, the reaction yield is 55.3%. When the concentration is 15%, it reaches the maximum value of 87.6%. The concentration is At 18%, the yield did not change significantly.

Embodiment 3

[0038] The concentration of ammonium persulfate-sodium bisulfite is 15%, and other conditions are as in Example 1. The optimal reaction temperature is 30, 40, 50, 60, 70, 80°C. When the temperature is 30°C, it can be seen from the experimental phenomenon that it is in a translucent state, the polymerization efficiency is poor, and the yield of the product is also low, only 25.6%. When the temperature is 40°C, the yield reaches a maximum of 89.6%. The temperature continued to rise, and the yield decreased, reaching 44.3% at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com