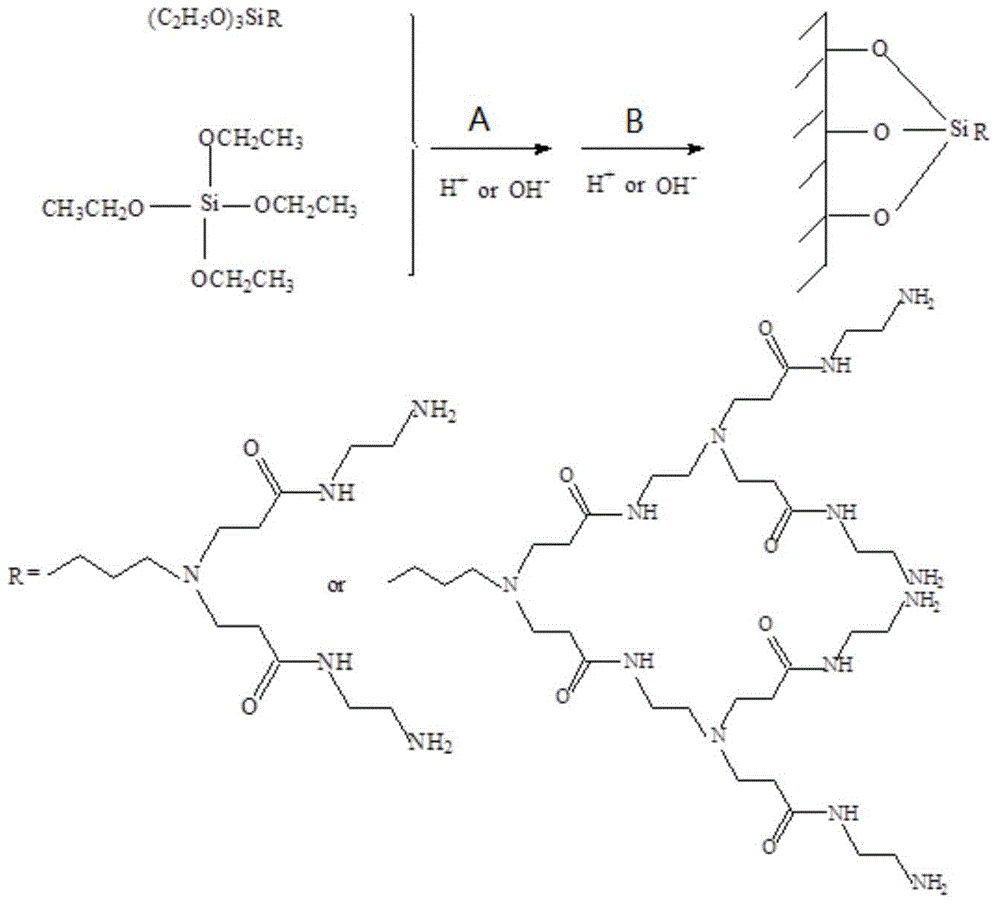

Preparation method of silica gel-bonded polyamidoamine (PAMAM) dendrimer adsorbent

A dendrimer-loaded polyamide technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as low metal ion adsorption and steric hindrance can reduce reaction cost, improve porosity and increase crosslinking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve 38 mL of redistilled methyl acrylate in 40 mL of methanol, and 35 mL of 3-aminopropyltriethoxysilane in 40 mL of methanol. Among them, the molar ratio of ester group to amine group is 5:2. At 0°C, under the protection of nitrogen, with magnetic stirring, slowly drop the methanol solution of aminopropyltrimethoxysilane into the methanol solution of methyl acrylate for about 2 hours After the dropwise addition was completed. Subsequently, at 0° C., the reaction was stirred for 0.5 hours, and then stirred and reacted at room temperature for 24 hours under nitrogen protection. After the reaction, the mixture was evaporated with a rotary evaporator at 40° C. to remove the solvent and excess methyl acrylate, and the final product was a G0.5PAMAM dendrimer. Dissolve 115mL of ethylenediamine in 120mL of methanol, and 25g of G0.5PAMAM dendrimer in 30mL of methanol. The molar ratio of amine groups to ester groups is about 25:1. 0°C, under nitrogen protection, magnet...

Embodiment 2

[0028] (1) Same as step (1) in Example 1 to obtain a G1.0 PAMAM dendrimer.

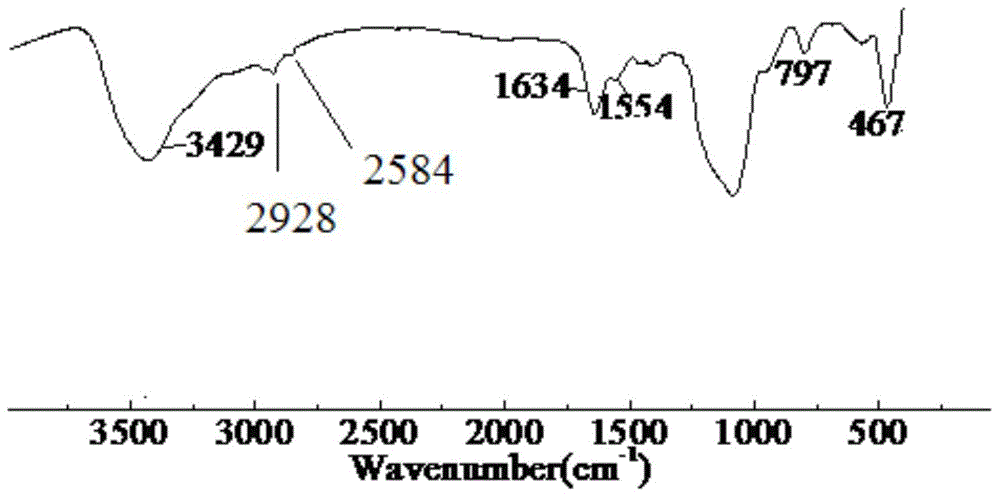

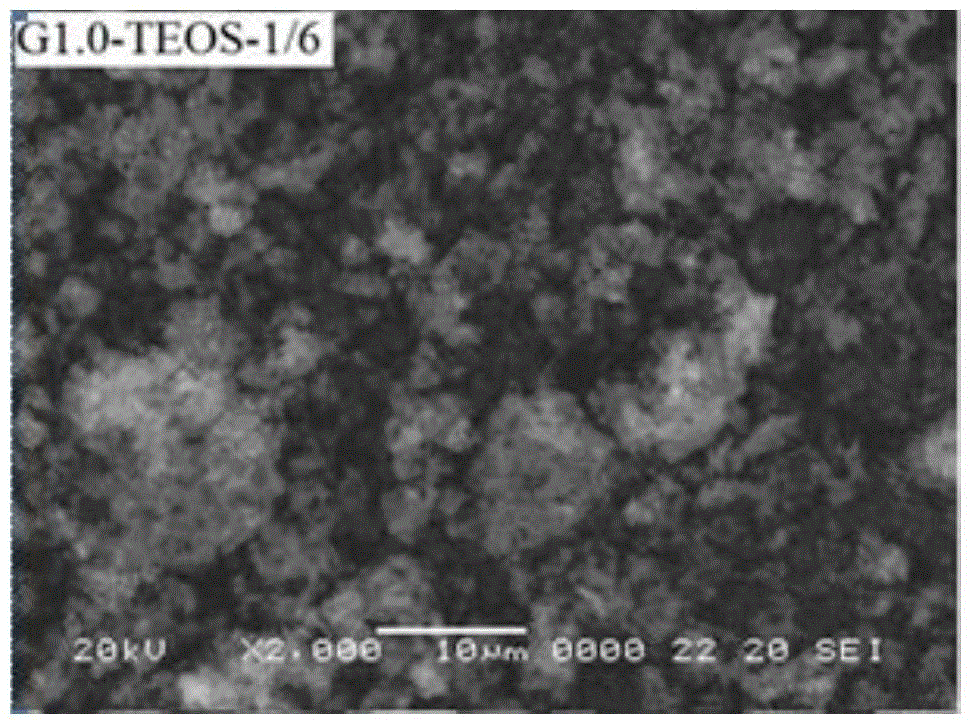

[0029] (2) Put 0.3620g of cetyltrimethylammonium bromide and 0.05g of sodium hydroxide into a three-necked bottle filled with 20ml of warm water, stir until it becomes clear, and then add G1.0 PAMAM dendrimers Bulk and tetraethoxysilane were added to the above clear liquid in a molar ratio of 1:6. At room temperature (25° C.), the stirring was continued, and the stirring reaction was continued for 24 hours after a white gel was formed. Subsequently, the above-mentioned white precipitated gel was transferred to a polypropylene bottle, heated at 70°C for 2h, then aged at 85°C for 4 days, filtered with suction, washed with water (washed with water until there was only a small amount of foam), and dried at room temperature. The obtained sample was transferred to a Soxhlet extractor, using absolute ethanol (210 mL) and hydrochloric acid (10 ml, 37 wt %) as solvents, and extracted under reflux for 72 h. T...

Embodiment 3

[0031] (1) Same as step (1) in Example 1 to obtain G2.0 PAMAM dendrimers.

[0032] (2) At 25°C, mix the G2.0 PAMAM-type dendrimer monomer and tetraethoxysilane at a molar ratio of 1:10, stir mechanically for 2 hours, then add 7ml of water, and dropwise add 4.5ml of NH 4 Solution F (0.014g / mL), continue to react for 24h after forming a white gel. After the reaction, the sample was aged at 40° C. for 48 h, filtered with suction, and dried at room temperature. Transfer the dried sample to a Soxhlet extractor and extract it with absolute ethanol for 48 hours, and dry the sample in a vacuum oven at 60°C for 48 hours, and the obtained product is marked as G2.0-TEOS-1 / 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com