Packaging lead wire material structure and processing method thereof

A wire material and processing method technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of poor yield, slow speed, complex circuits, etc., and improve the ability of electron transmission , Reduce the amount of gold used, the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

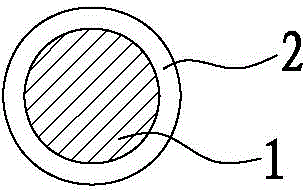

[0020] Such as figure 1 As shown, the structure of a package wire material disclosed by the present invention is composed of an intermediate core 1 and a surface coating 2, the intermediate core 1 is a tungsten wire, the diameter of the tungsten wire is preferably 12.7 microns, the surface coating 2 is gold, and the surface coating The thickness is preferably 2 microns, thereby forming a structure of tungsten inside and gold outside.

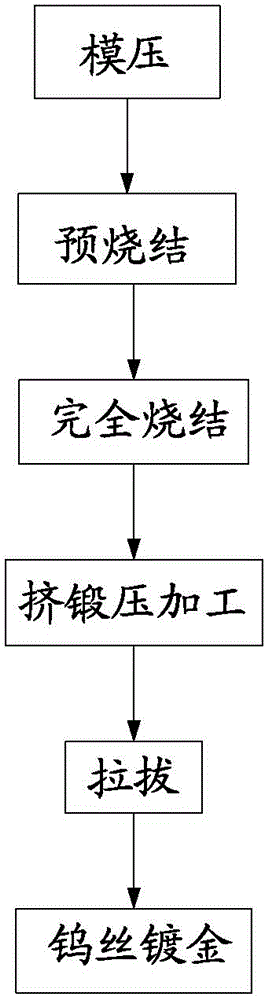

[0021] Such as figure 2 As shown, a packaging wire material disclosed in the present invention is processed according to the following steps.

[0022] The first step, molding.

[0023] Put a fixed weight of tungsten powder into a stainless steel mold and extrude it into a whole rod.

[0024] The second step is pre-sintering.

[0025] Place the fragile rod in the first step in a refractory metal vessel and put it into a hydrogen sintering furnace at a high temperature of 1200-1600°C to continuously agglomerate the metal particles; during thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com