Method for deeply treating sewage by using calcined pyrite as filtering material

An advanced treatment, pyrite technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of low concentration of anaerobic denitrification microorganisms, low treatment efficiency, poor treatment effect, etc., and achieve simultaneous denitrification and phosphorus removal to reduce organic pollutants effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Non-limiting examples of the present invention are as follows:

[0039] Hand-selected ore from pyrite mines, the mass percentage of pyrite is 95%, and a small amount of impurities is quartz. Crushing and screening to obtain pyrite particles with a particle size in the range of 0.2-0.6mm;

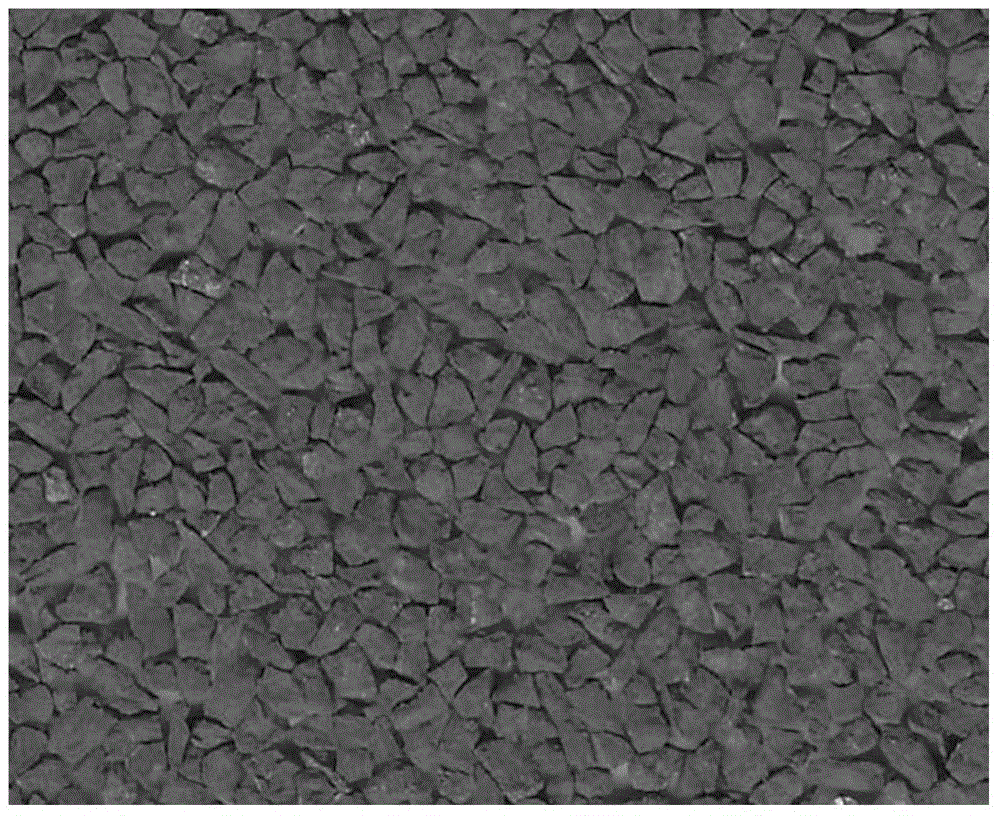

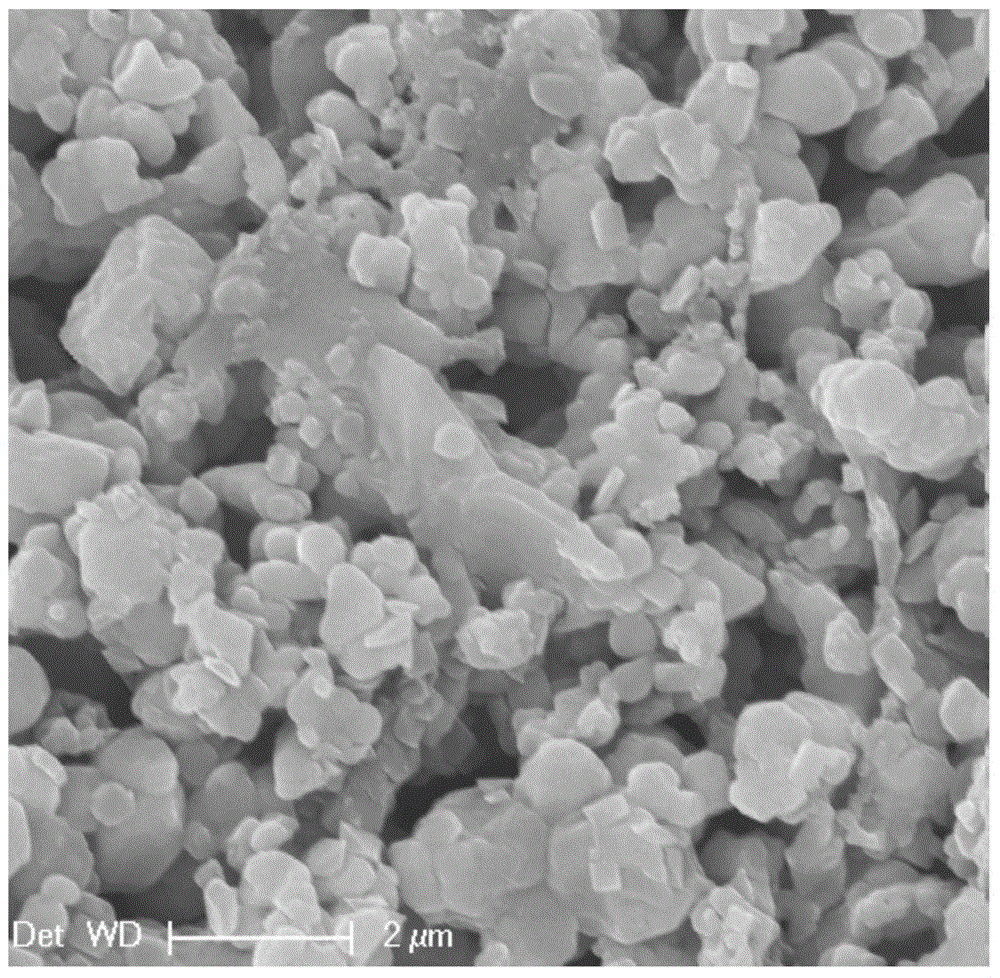

[0040] The pyrite particles are calcined in a boiling furnace at 750°C under a protective atmosphere, so that the pyrite can be completely and quickly converted into pyrrhotite to obtain calcined pyrite; figure 1 This is a photo of the filter material in the filter tank prepared by the present invention. figure 2 It is a field emission scanning electron microscope image of calcined pyrite. It can be seen that the calcined pyrite has a porous structure.

[0041] Use PVC pipes with a diameter of 30 mm and a length of 2000 mm to set up glass pipes with a diameter of 6 mm from bottom to top at 200 mm intervals, which are used as water inlets and outlets and sampling ports along the way to cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com