Method for preparing TiO2/Ta2O5 composite coating with special micro nano structure

A composite coating, micro-nano structure technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of hindering promotion, poor corrosion resistance, lack of biological activity of the coating, etc., to facilitate the promotion. , the process is simple, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

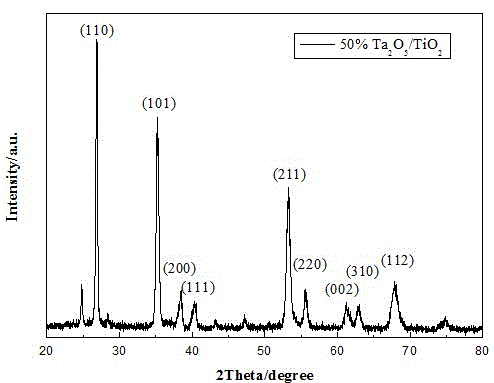

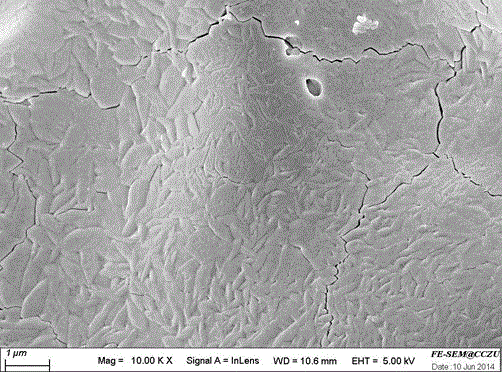

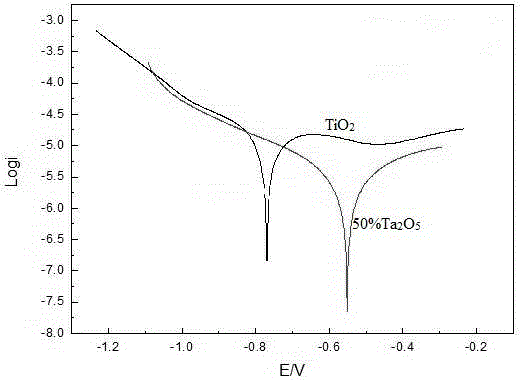

[0026] (1) Preparation of spray powder: TiO by mass ratio 2 Powder 50%, Ta 2 o 5Powder 50%, weighing 200 g, binder polyvinyl alcohol 20 g, using a planetary ball mill, mixing at a speed of 380 r / min for 2 h, then putting the uniformly mixed slurry in an oven at 80 ° C for drying, grinding, Sieve, get the fine powder between 200-300 mesh, set aside.

[0027] (2) Material cleaning and sandblasting: Use a 10 mm×10 mm×1 mm sheet-shaped titanium alloy Ti-6Al-4V substrate, ultrasonically clean it with acetone, ethanol and deionized water, and air-dry; use a particle size of 350 -500 μm brown corundum sand is used to roughen the surface of the substrate by sandblasting to improve the roughness of the substrate surface.

[0028] (3) Plasma spraying: use atmospheric plasma spraying equipment to prepare TiO on the surface of the substrate treated in step 2 2 / 50%Ta 2 o 5 Composite coating, the spraying process is realized by controlling the following parameters: main gas Ar 40 L / m...

Embodiment 2

[0032] (1) Preparation of spray powder: TiO by mass ratio 2 Powder 60%, Ta 2 o 5 Powder 40%, weighing 200 g, binder polyvinyl alcohol 20 g, using a planetary ball mill, mixing at a speed of 380 r / min for 2 h, then putting the uniformly mixed slurry in an oven at 80 ° C for drying, grinding, Sieve, get the fine powder between 200-300 mesh, set aside.

[0033] (2) Material cleaning and sandblasting: Use a 10 mm×10 mm×1 mm sheet-shaped titanium alloy Ti-6Al-4V substrate, ultrasonically clean it with acetone, ethanol and deionized water, and air-dry; use a particle size of 350 -500 μm brown corundum sand is used to roughen the surface of the substrate by sandblasting to improve the roughness of the substrate surface.

[0034] (3) Plasma spraying: use atmospheric plasma spraying equipment to prepare TiO on the surface of the substrate treated in step 2 2 / 40%Ta 2 o 5 Composite coating, the spraying process is realized by controlling the following parameters: main gas Ar 40 L / ...

Embodiment 3

[0038] (1) Preparation of spray powder: TiO by mass ratio 2 Powder 70%, Ta 2 o 5 Powder 30%, weighing 200 g, binder polyvinyl alcohol 20 g, using a planetary ball mill, mixing at a speed of 380 r / min for 2 h, then putting the uniformly mixed slurry in an oven at 80 ° C for drying, grinding, Sieve, get the fine powder between 200-300 mesh, set aside.

[0039] (2) Material cleaning and sandblasting: Use a 10 mm×10 mm×1 mm sheet-shaped titanium alloy Ti-6Al-4V substrate, ultrasonically clean it with acetone, ethanol and deionized water, and air-dry; use a particle size of 350 -500 μm brown corundum sand is used to roughen the surface of the substrate by sandblasting to improve the roughness of the substrate surface.

[0040] (3) Plasma spraying: use atmospheric plasma spraying equipment to prepare TiO on the surface of the substrate treated in step 2 2 / 30%Ta 2 o 5 Composite coating, the spraying process is realized by controlling the following parameters: main gas Ar 40 L / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com