A kind of bath for electroplating nano-pearl zinc and preparation method thereof

A technology of nano pearls and pearl zinc, applied in the fields of nanotechnology, nanotechnology and nanotechnology for material and surface science, can solve the problems of process pollutants exceeding the requirements of environmental protection, poor chemical polishing, and large environmental pollution, etc. Achieve the effect of small voids, easy diffuse reflection and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method based on a plating solution for electroplating nano-pearl zinc, comprising the following steps:

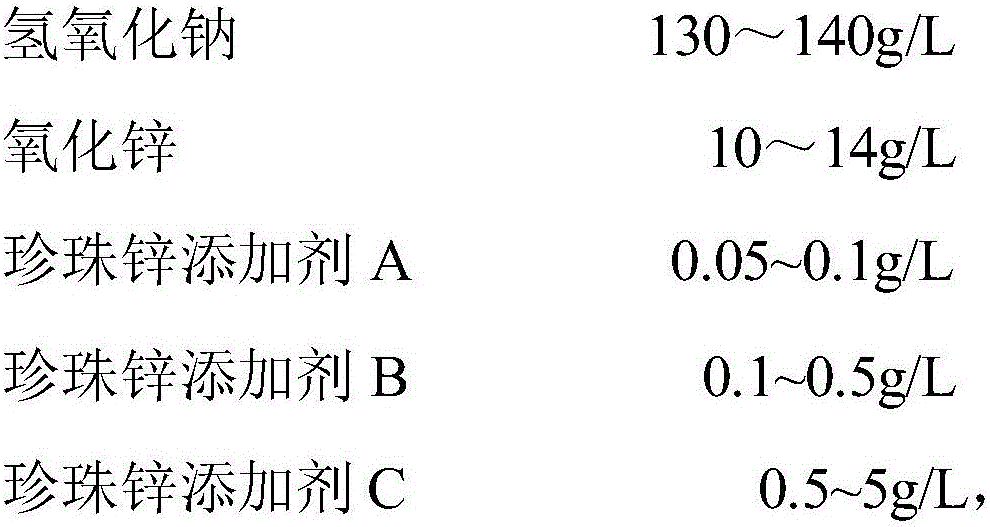

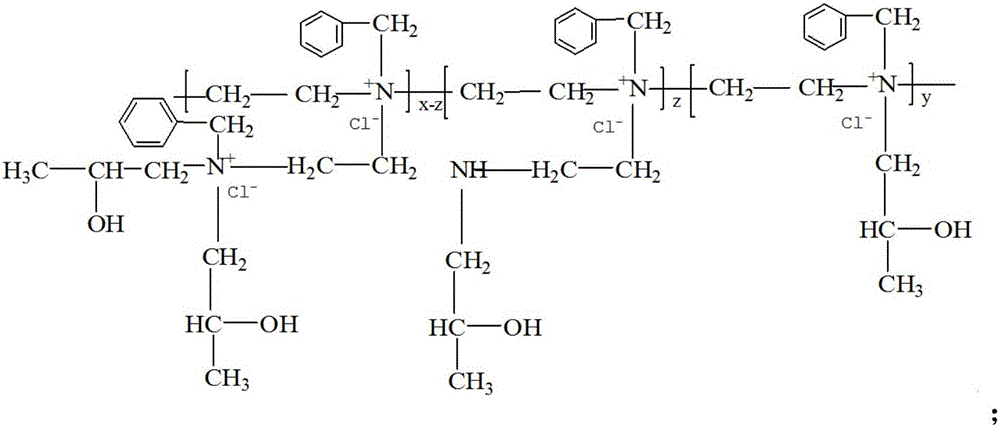

[0046] S1. Prepare quaternized polyethyleneimine, 2-[(aminoiminomethyl)thio]nicotinic acid and alkylpolyethylenepolyamine, and weigh 0.05~0.1 parts of quaternized polyethyleneimine respectively according to mass ratio , 0.1 to 0.5 parts of 2-[(aminoiminomethyl)thio]nicotinic acid, 0.5 to 5 alkylpolyethylene polyamines, and sequentially configured into quaternized polyethyleneimine solution, 2-[(aminoimino Methyl) sulfur] nicotinic acid solution and alkyl polyethylene polyamine solution, by volume ratio, quaternized polyethyleneimine solution: 2-[(aminoiminomethyl) sulfur] nicotinic acid solution: alkyl poly Ethylene polyamine solution = 1:5:10.

[0047] S2. Weigh 130-140 parts of solid sodium hydroxide and 10-14 parts of zinc oxide according to the mass ratio, add them into the plating tank, and stir evenly.

[0048] S3. Add 250 parts of water and kee...

Embodiment 1

[0074] A plating solution for electroplating nano-pearl zinc, the components include 1000g water, 130g sodium hydroxide, 12g zinc oxide, 0.05g quaternized polyethyleneimine, 0.1g2-[(aminoiminomethyl)sulfur] Niacin, 0.5g alkyl polyethylene polyamine.

[0075] The preparation process is: first prepare quaternized polyethyleneimine, 2-[(aminoiminomethyl)thio]nicotinic acid and alkylpolyethylene polyamine according to the above method, and weigh 0.05g of quaternized polyethyleneimine Amine, 0.1g 2-[(aminoiminomethyl)sulfur]nicotinic acid, 0.5g alkylpolyethylene polyamine, sequentially configured into quaternized polyethyleneimine solution, 2-[(aminoiminomethyl)sulfur ] nicotinic acid solution and alkylpolyethylene polyamine solution; then take by weighing 130g sodium hydroxide and 12g zinc oxide and add in the plating tank, and stir evenly; Add 250g water, stir constantly, make above-mentioned solid dissolve completely; Add 250g water and mix Stir fully to form a liquid; after co...

Embodiment 2

[0077] A plating solution for electroplating nano-pearl zinc, the components include 1000g water, 130g sodium hydroxide, 12g zinc oxide, 0.075g quaternized polyethyleneimine, 0.25g2-[(aminoiminomethyl)sulfur] Niacin, 2.5g alkylpolyethylenepolyamine.

[0078]The preparation process is as follows: first prepare quaternized polyethyleneimine, 2-[(aminoiminomethyl)thio]nicotinic acid and alkylpolyethylene polyamine according to the above method, and weigh 0.075g of quaternized polyethyleneimine . ] nicotinic acid solution and alkylpolyethylene polyamine solution; then take by weighing 130g sodium hydroxide and 12g zinc oxide and add in the plating tank, and stir evenly; Add 250g water, stir constantly, make above-mentioned solid dissolve completely; Add 250g water and mix Stir fully to form a liquid; after cooling, add 1g of impurity remover to the above liquid, stir fully for 0.5-1h, and filter after standing still for 2-3h; add the above-mentioned quaternized polyethyleneimine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com