Preparation method of two-dimensional inorganic layered compound/graphene composite material

A technology of layered compounds and composite materials, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, electrical components, etc., can solve the problem of high equipment requirements, achieve low equipment requirements, prevent agglomeration, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

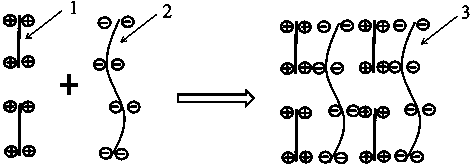

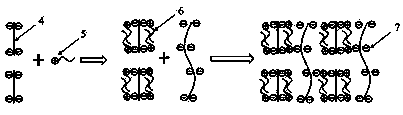

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 2.617g of analytically pure nickel nitrate and 1.125g of analytically pure aluminum nitrate in 50ml of deionized water, dissolve 2.4g of urea in 50ml of deionized water, mix the two solutions evenly, and transfer them to a high-pressure reactor at 100°C React for 24 hours, filter, wash, and vacuum-dry at 60°C to obtain nickel-aluminum double metal hydroxide. Add 1g of nickel-aluminum double hydroxide to 1000ml solution containing 1.5M sodium nitrate and 0.005M nitric acid, and blow nitrogen into the solution for 15min to drive off carbon dioxide. The above solution was shaken at room temperature for 1 day, and the obtained product was filtered, washed, and vacuum-dried at 60° C. to obtain an anion-exchanged nickel-aluminum double metal hydroxide. Mix the anion-exchanged nickel-aluminum double metal hydroxide and formamide solution at a mass ratio of 1:1, shake for 1 day, centrifuge at 2000rpm to take the supernatant, and obtain the stripped positively charged l...

Embodiment 2

[0023] Dissolve 1.746g of analytically pure nickel nitrate and 1.125g of analytically pure aluminum nitrate in 50ml of deionized water, dissolve 1.8g of urea in 50ml of deionized water, mix the two solutions evenly, and transfer them to an autoclave at 100°C React for 24 hours, filter, wash, and vacuum-dry at 60°C to obtain nickel-aluminum double metal hydroxide. Add 1g of nickel-aluminum double hydroxide to 1000ml solution containing 1.5M sodium nitrate and 0.005M nitric acid, and blow nitrogen into the solution for 15min to drive off carbon dioxide. The above solution was shaken at room temperature for 1 day, and the obtained product was filtered, washed, and vacuum-dried at 60° C. to obtain an anion-exchanged nickel-aluminum double metal hydroxide. Mix the anion-exchanged nickel-aluminum double metal hydroxide and formamide solution at a mass ratio of 1:1, shake for 1 day, centrifuge at 2000rpm to take the supernatant, and obtain the stripped positively charged layered nick...

Embodiment 3

[0025] Dissolve 2.619g of analytically pure cobalt nitrate and 1.125g of analytically pure aluminum nitrate in 50ml of deionized water, dissolve 2.4g of urea in 50ml of deionized water, mix the two solutions evenly, and transfer them to an autoclave at 120°C React for 24 hours, filter, wash, and vacuum dry at 60°C to obtain a cobalt-aluminum double metal hydroxide. Add 1g of cobalt-aluminum double metal hydroxide to 1000ml solution containing 1.5M sodium nitrate and 0.005M nitric acid, and blow nitrogen into the solution for 15 minutes to drive off carbon dioxide. The above solution was shaken at room temperature for 1 day, and the obtained product was filtered, washed, and vacuum-dried at 60° C. to obtain an anion-exchanged cobalt-aluminum double metal hydroxide. Mix the anion-exchanged cobalt-aluminum double hydroxide and formamide solution at a mass ratio of 1:5, shake for 1 day, centrifuge at 2000rpm to take the supernatant, and obtain the exfoliated layered cobalt-aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com