Agaric culture medium

A technology of culture medium and fungus, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of lack of science, increased harm of miscellaneous bacteria pollution, extensive cultivation methods, etc., to improve survival rate, reduce miscellaneous bacteria pollution, fully The effect of using resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

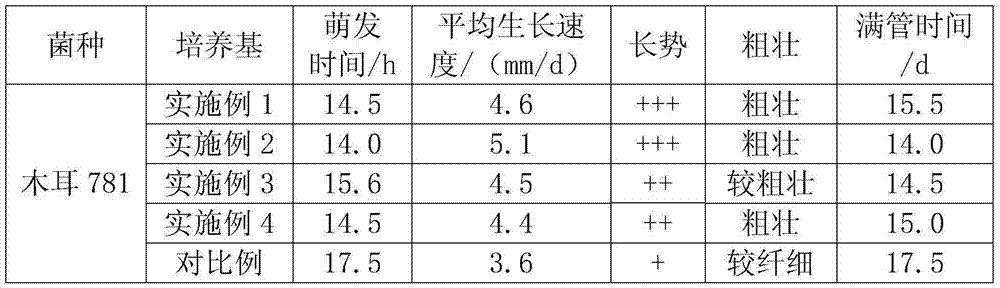

Examples

Embodiment 1

[0022] A fungus culture medium is made of the following raw materials in weight percentage: 55% of paulownia sawdust, 13% of cottonseed hulls, 10% of corn flour, 12% of wheat bran, 6.9% of mangosteen pomace, 1.1% of gypsum, and 2% of sucrose.

[0023] The preparation method of fungus culture medium, comprises the steps:

[0024] (1) paulownia sawdust is crushed into 1mm particles, dried, and Luo Han pomace is crushed into 50 mesh fine powder;

[0025] (2) Mix paulownia wood chips, gypsum, cottonseed hulls, corn flour, wheat bran, and Luo Han pomace fine powder, dissolve sucrose in water and pour into the mixture, spray water while stirring until the moisture content is 55%, and pile up 1 day;

[0026] (3) Put the culture medium into a polyethylene material film barrel bag, bag 250g / bag, and then sterilize it in steam at 110°C for 8 hours, and cool it to 26°C to obtain the fungus culture medium.

Embodiment 2

[0028] A fungus culture medium is made of the following raw materials in weight percentage: 61.5% of poplar wood chips, 15% of corncobs, 5% of cottonseed hulls, 10% of wheat bran, 6% of mangosteen pomace, 1.0% of gypsum, and 1.5% of sucrose.

[0029] The preparation method of fungus culture medium, comprises the steps:

[0030] (1) poplar wood chips are crushed into 1.5mm particles, dried, and the grosvenor pomace is crushed into 80 mesh fine powder;

[0031] (2) Mix poplar wood chips, gypsum, corncobs, cottonseed hulls, wheat bran, and Luo Han fruit pomace powder, dissolve sucrose in water and pour into the mixture, spray water while stirring until the moisture content is 60%, and pile up 1.5 days;

[0032] (3) Put the culture medium into a polyethylene material film barrel bag, bag 250g / bag, and then sterilize in steam at 110°C for 10 hours, and cool to 25°C to obtain the fungus culture medium.

Embodiment 3

[0034] A fungus culture medium is prepared from the following raw materials in weight percentage: 63.2% of linden wood chips, 30% of corn flour, 5% of mangosteen pomace, 0.8% of gypsum, and 1.0% of glucose.

[0035] The preparation method of fungus culture medium, comprises the steps:

[0036] (1) the linden tree chips are crushed into 1.5mm particles, dried, and the grosvenor pomace is crushed into 90 mesh fine powder;

[0037] (2) Mix linden wood chips, corn flour, gypsum, and Luo Han Guo pomace fine powder, dissolve glucose in water and pour into the mixture, spray water while stirring until the water content is 60%, and stack for 1 day;

[0038] (3) Put the culture medium into a polyethylene material film barrel bag, bag 250g / bag, and then sterilize it in steam at 110°C for 11 hours, and cool it to 24°C to obtain the fungus culture medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com