Cationic starch and its preparation method and application

A cationic starch, starch technology, applied in textiles and papermaking, water repellent addition, coating and other directions, can solve the problems of short stability time, uneven reaction, low electric double layer charge of AKD emulsion, and achieve good emulsion stabilization effect , to ensure the reaction efficiency and reduce the effect of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

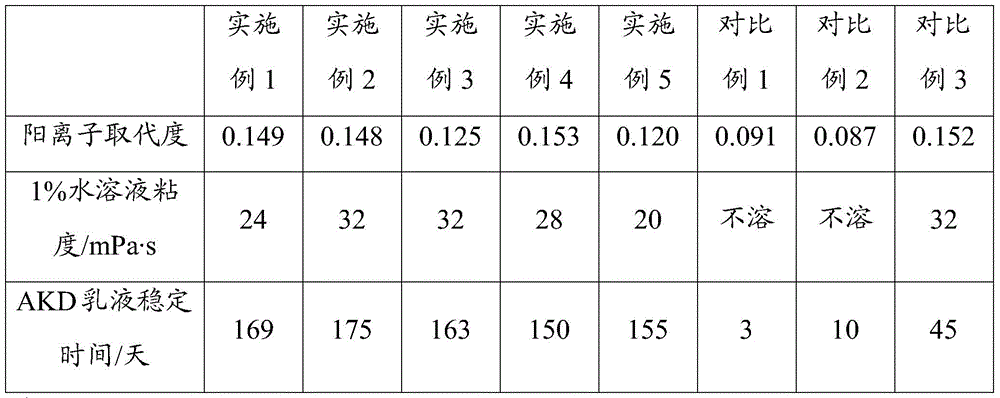

Examples

Embodiment 1

[0034] A kind of preparation method of cationic starch of the present embodiment, comprises the steps:

[0035] (1) 100g of corn starch and 300g of 75% ethanol aqueous solution are mixed and placed in a reaction vessel, and stirred for 30min;

[0036] (2) Add 7g of sodium hydroxide, stir and heat up to 55°C;

[0037] (3) Add 25g of 2,3-epoxypropyltrimethylammonium chloride etherification agent, and react for 5h;

[0038] (4) Add 3g hydrogen peroxide and react for 30min;

[0039] (5) adding glacial acetic acid to the pH value of the reaction system is 4-7;

[0040] (6) Vacuum-dry directly in a reaction vessel at a temperature of 60° C. and a vacuum degree of 0.09 MPa, pulverize and sieve to obtain the cationic starch.

Embodiment 2

[0042] A kind of preparation method of cationic starch of the present embodiment, comprises the steps:

[0043] (1) 100g tapioca starch is mixed with 250g mass percentage content of 70% ethanol aqueous solution and then placed in a reaction vessel and stirred for 30min;

[0044] (2) Add 8g of potassium hydroxide, stir and heat up to 60°C;

[0045] (3) Add 25g of 2,3-epoxypropyltrimethylammonium chloride etherification agent, and react for 4h;

[0046] (4) Add 4g hydrogen peroxide, react for 30min;

[0047] (5) adding hydrochloric acid to the pH value of the reaction system is 4-7;

[0048] (6) Vacuum dry directly in a reaction vessel at a temperature of 70° C. and a vacuum degree of 0.09 MPa, pulverize and sieve to obtain the cationic starch.

Embodiment 3

[0050] A kind of preparation method of cationic starch of the present embodiment, comprises the steps:

[0051] (1) 100g of wheat starch and 200g of 80% ethanol aqueous solution are mixed and then placed in a reaction vessel and stirred for 30 minutes;

[0052] (2) Add 10g of potassium hydroxide, stir and heat up to 65°C;

[0053] (3) Add 30g of 3-chloro-2-hydroxypropyl-trimethylammonium chloride etherifying agent and react for 3h;

[0054] (4) Add 5g hydrogen peroxide and react for 30min;

[0055] (5) adding citric acid to the pH value of the reaction system is 4-7;

[0056] (6) Vacuum dry directly in a reaction vessel at a temperature of 75° C. and a vacuum of 0.085 MPa, pulverize and sieve to obtain the cationic starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com