Production method for preparing hydrolyzed wheat proteins by fermentation method

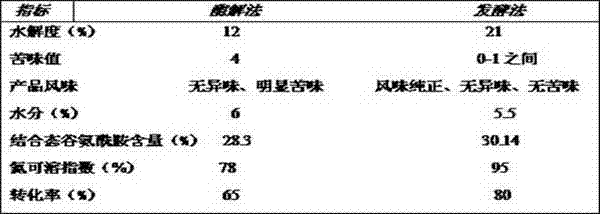

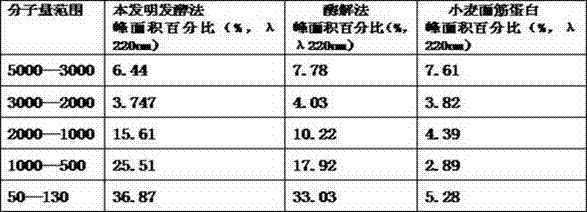

A technology of wheat hydrolyzed protein and production method, which is applied in the field of preparing wheat hydrolyzed protein by fermentation method, can solve the problems of affecting the taste and flavor of products, popularization and application, easy damage of amino acids, unstable product quality, etc., and achieves significant social and economic benefits and economical benefits. Significant social benefits and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Transfer the activated Aspergillus oryzae strain (Aspergillu) into the liquid seed medium, culture it at 33°C, 200r / min for 36 hours, and use it for fermentation when a uniform small hyphae ball is formed; at the same time, the activated Bacillus subtilis The bacterial strain (Bacillus subtilis) was inoculated in the seed medium, and cultured with shaking at 37°C and 120r / min for about 24h, so that the bacterial cell concentration reached 10 6 -10 8 CFU / mL for use. Take wheat gluten protein powder, add wheat gluten protein powder and water in fermenter and be configured to be 6% by weight percentage concentration, add relative to the growth nutrition bag of wheat gluten protein quality 0.2%, control glucose, sodium chloride in the nutrition bag , potassium dihydrogen phosphate, and dipotassium hydrogen phosphate in a weight ratio of 100:1:1:0.5, adjust the pH to 6.0, then sterilize and cool down to 33°C, and insert the above-mentioned cultivated mature Bacillus subtili...

Embodiment 2

[0025] Transfer the activated Aspergillus oryzae strain (Aspergillu) into the liquid seed medium, culture it at 33°C, 200r / min for 36 hours, and use it for fermentation when a uniform small hyphae ball is formed; at the same time, the activated Bacillus subtilis The bacterial strain (Bacillus subtilis) was inoculated in the seed medium, and cultured with shaking at 37°C and 120r / min for about 24h, so that the bacterial cell concentration reached 10 6 -10 8 CFU / mL for use. Take wheat gluten protein powder, add wheat gluten protein powder and water in fermenter and be configured to be 7% by weight percentage concentration, add relative to the growth nutrition bag of wheat gluten protein quality 0.2%, control glucose, sodium chloride in the nutrition bag , potassium dihydrogen phosphate, and dipotassium hydrogen phosphate in a weight ratio of 100:1.5:1.5:0.6, adjust the pH to 6.5, then sterilize and cool down to 34°C, insert the above-mentioned cultivated mature Bacillus subtili...

Embodiment 3

[0027] Transfer the activated Aspergillus oryzae strain (Aspergillu) into the liquid seed medium, culture it at 33°C, 200r / min for 36 hours, and use it for fermentation when a uniform small hyphae ball is formed; at the same time, the activated Bacillus subtilis The bacterial strain (Bacillus subtilis) was inoculated in the seed medium, and cultured with shaking at 37°C and 120r / min for about 24h, so that the bacterial cell concentration reached 10 6 -10 8 CFU / mL for use. Take wheat gluten protein powder, add wheat gluten protein powder and water in fermenter and be configured to be 8% by weight percentage concentration, add relative to the growth nutrition bag of wheat gluten protein quality 0.2%, control glucose, sodium chloride in the nutrition bag , potassium dihydrogen phosphate, and dipotassium hydrogen phosphate in a weight ratio of 100:2:1:0.3, adjust the pH to 7.0, then sterilize and cool down to 35°C, and insert the above-mentioned cultivated mature Bacillus subtili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com