Method for electric field-induced conversion of water and CO2 to organic polymer

An electric field induction, polymer technology, applied in the field of electrochemistry and artificial photosynthesis, achieves huge development potential, avoids enzyme-catalyzed reactions, and improves efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

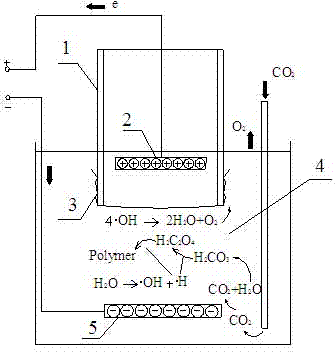

[0042] Assembling an electric field induction reactor such as figure 1 As shown: an anode plate 2 is installed in the anode chamber 1, a cathode plate 5 is installed in the cathode chamber 4, and a diaphragm 3 is used to isolate the anode chamber 1 and the cathode chamber 4. The anode plate 2 is a titanium metal electrode, the cathode plate 5 is a nickel-iron-chromium alloy electrode, and the diaphragm is a cation exchange membrane. Add water to the cathode chamber 4, and adjust the pH value to 7.5 with sodium carbonate, add nickel nitrate as a catalyst; open the cathode chamber 4, and allow the aqueous solution to automatically absorb CO in the atmosphere under normal temperature and pressure conditions. 2 . Insert the anode chamber 1 into the cathode chamber 4, and inject an appropriate amount of sodium carbonate aqueous solution into the anode chamber 4. Through the wire DC power supply, after checking the circuit, select the output voltage to be 5.0V, and control the cur...

Embodiment 2

[0044] Assembling an electric field induction reactor such as figure 1 As shown: an anode plate 2 is installed in the anode chamber 1, a cathode plate 5 is installed in the cathode chamber 4, and a diaphragm 3 is used to isolate the anode chamber 1 and the cathode chamber 4. The anode plate 2 is a graphite electrode, the cathode plate 5 is a nickel electrode, and the diaphragm is a microfiltration membrane. Add water to the cathode chamber 4, and adjust the pH value to 7.2 with sodium hydroxide, add chromium nitrate as a catalyst; open the cathode chamber 4, and allow the aqueous solution to automatically absorb CO in the atmosphere under normal temperature and pressure conditions. 2 . Insert the anode chamber 1 into the cathode chamber 4, and inject an appropriate amount of sodium hydroxide aqueous solution into the anode chamber 4. Through the wire DC power supply, after checking the circuit, select the output voltage as 2.0V, and control the current density to be less tha...

Embodiment 3

[0046] Assembling an electric field induction reactor such as figure 1 As shown: an anode plate 2 is installed in the anode chamber 1, a cathode plate 5 is installed in the cathode chamber 4, and a diaphragm 3 is used to isolate the anode chamber 1 and the cathode chamber 4. The anode plate 2 is a ruthenium oxide electrode, the cathode plate 5 is a nickel-chromium alloy electrode, and the diaphragm is a nanofiltration membrane. Add water to the cathode chamber 4, and adjust the pH value to 8.0 with sodium hydroxide, add ferric nitrate as a catalyst; open the cathode chamber 4, and allow the aqueous solution to automatically absorb CO in the atmosphere under normal temperature and pressure conditions. 2 . Insert the anode chamber 1 into the cathode chamber 4, and inject an appropriate amount of sodium hydroxide aqueous solution into the anode chamber 4. Through the wire DC power supply, after checking the circuit, select the output voltage as 12.0V, and control the current de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com