Method for producing nanometer particles through nanometer emulsification technology

A nano-particle and nano-technology, applied in the field of nano-particle preparation, can solve the problems of insolubility of curcumin in water, low absorption rate and narrow application range, and achieve the effects of improving bioavailability, low production cost and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

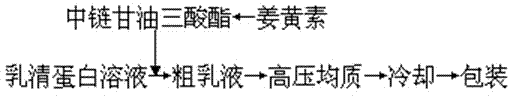

[0018] Specific implementation mode one: as figure 1 As shown, this embodiment provides a method for producing nanoparticles using nanoemulsion technology, and the production steps are as follows:

[0019] (1) Dissolve whey protein isolate (protein content ≥90%) in 0.05 M, pH=7 phosphate buffer solution, stir for 2 h, and prepare 1.25 g / 100 mL whey protein solution.

[0020] (2) Heat medium-chain triglycerides to 110°C, then add curcumin into the hot medium-chain triglycerides, and make it fully dissolve to prepare 0.1 g / 100 mL curcumin oil solution.

[0021] (3) Mix curcumin medium-chain triglyceride oil solution cooled to room temperature with whey protein aqueous solution, and use a high-shear emulsifier to stir at 11,000 rpm / min for 5 minutes to prepare a coarse emulsion. The oil phase (medium chain triglycerides) in the emulsion is 5% (v / v), and the water phase (whey protein solution) is 95% (v / v).

[0022] (4) The coarse emulsion was circulated and homogenized three ti...

specific Embodiment approach 2

[0023] Specific embodiment two: This embodiment provides a method for producing nanoparticles using nanoemulsification technology, and its production steps are as follows:

[0024] (1) Dissolve whey protein isolate (protein content ≥90%) in 0.05M, pH=7 phosphate buffer solution, stir for 3 hours, and prepare 2.5 g / 100 mL whey protein solution.

[0025] (2) Heat medium-chain triglycerides to 120°C, then add curcumin into the hot medium-chain triglycerides and dissolve them fully to prepare a 0.5 g / 100 mL curcumin oil solution.

[0026] (3) Mix curcumin medium-chain triglyceride oil solution cooled to room temperature with whey protein aqueous solution, and use a high-shear emulsifier to stir at 12000 rpm / min for 6 minutes to prepare a coarse emulsion. The oil phase (medium chain triglycerides) in the emulsion accounts for 10% (v / v), and the water phase (whey protein solution) accounts for 90% (v / v).

[0027] (4) The coarse emulsion was circulated and homogenized three times un...

specific Embodiment approach 3

[0028] Specific Embodiment Three: This embodiment provides a method for producing nanoparticles using nanoemulsification technology, and its production steps are as follows:

[0029] (1) Dissolve whey protein isolate (protein content ≥90%) in 0.05M, pH=7 phosphate buffer solution, stir for 5 hours, and prepare 7 g / 100 mL whey protein solution.

[0030] (2) Heat medium-chain triglycerides to 140°C, then add curcumin into the hot medium-chain triglycerides and dissolve them fully to prepare a 1 g / 100 mL curcumin oil solution.

[0031] (3) Mix curcumin medium-chain triglyceride oil solution cooled to room temperature with whey protein aqueous solution, and use a high-shear emulsifier to stir at 13,000 rpm / min for 10 minutes to prepare a coarse emulsion. The oil phase (medium chain triglycerides) in the emulsion accounts for 30% (v / v), and the water phase (whey protein solution) accounts for 70% (v / v).

[0032] (4) The coarse emulsion was circulated and homogenized three times un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com