Preparation method of polymethyl methacrylate macroporous microsphere adsorbent

A polymethyl methacrylate, macroporous microsphere technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve epilepsy, disturbance of consciousness, endocrine disruption, etc. problem, to achieve the effect of high specific surface area and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

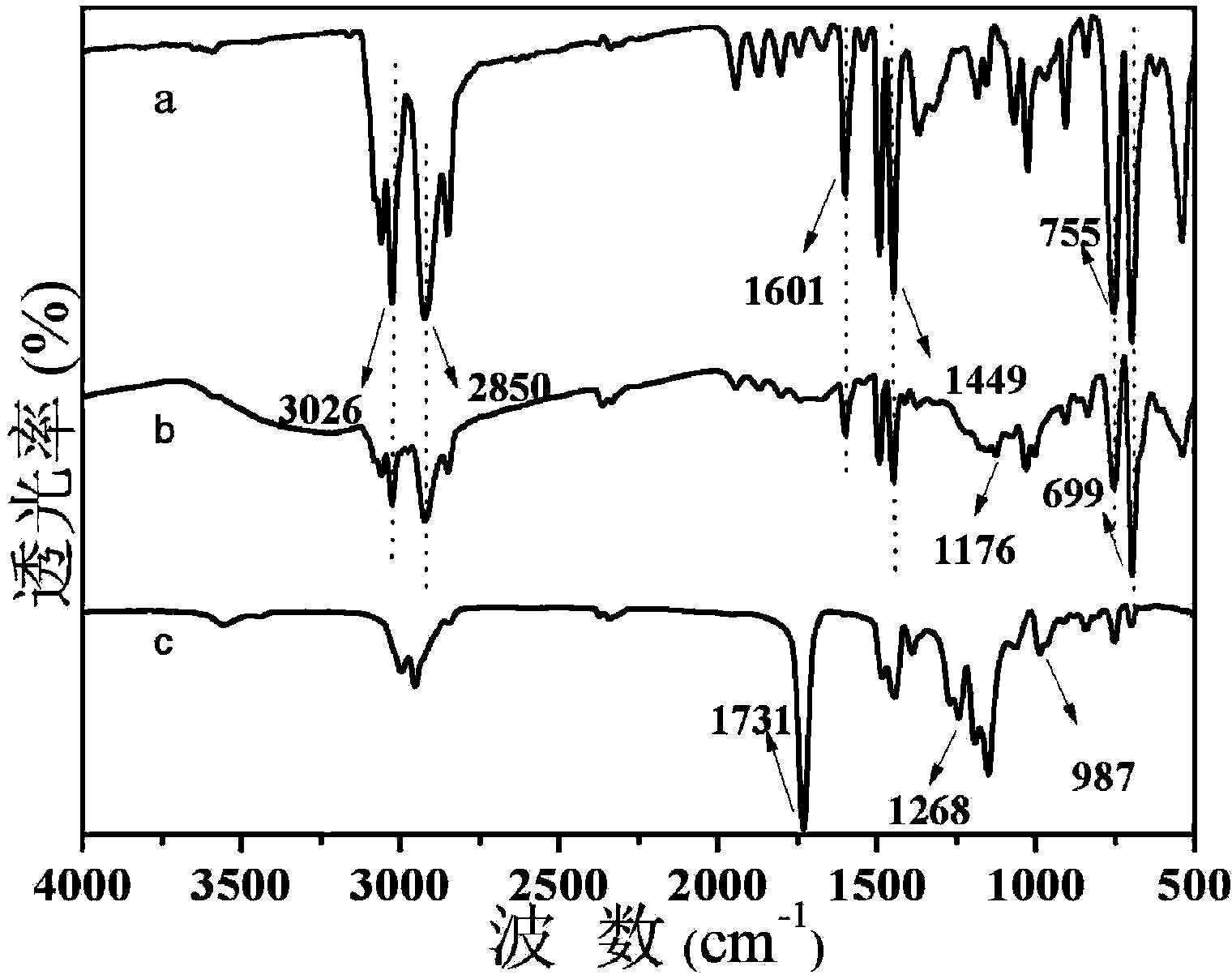

[0038] 1. A method for preparing macroporous polymethyl methacrylate microsphere adsorbent by polymerization, the steps are:

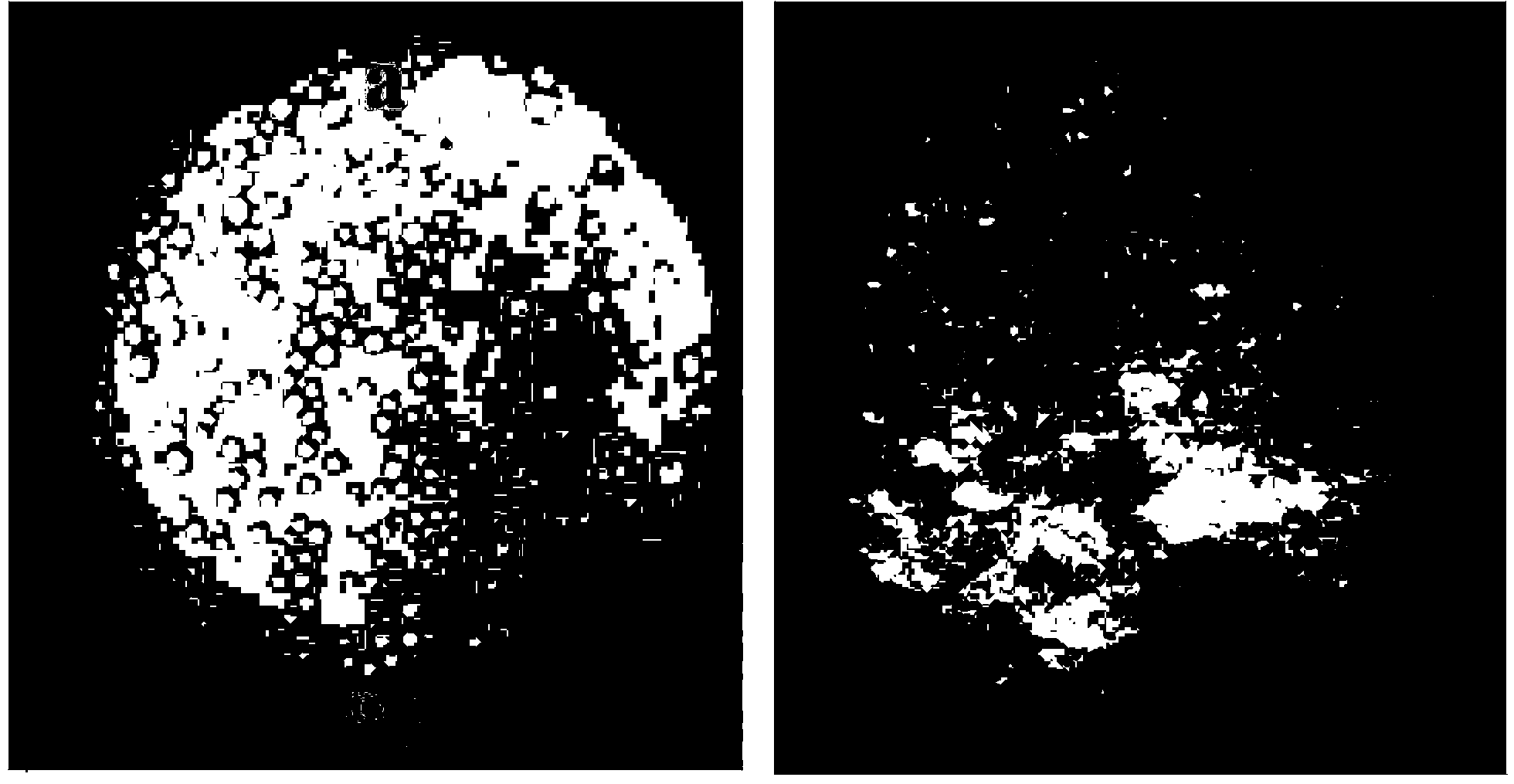

[0039] (1) Preparation of monodisperse non-crosslinked polystyrene microspheres

[0040] 1.5g of polyvinylpyrrolidone powder was dissolved in the mixed solution of 95ml of absolute ethanol and 5ml of deionized water, and after being ultrasonically dispersed for 10 minutes, it was put into a three-necked flask equipped with nitrogen, a stirrer, and a condenser tube, and then mechanically Nitrogen was blown under stirring for half an hour. After fully removing the dissolved oxygen therein, add 25ml of styrene monomer dissolved in 0.2g of azobisisobutyronitrile under mechanical stirring, then react in a water bath at 70°C for 24 hours, and centrifuge to collect polystyrene particles after the reaction is complete. ball. The polystyrene microspheres were washed several times with a 1:3 solution of absolute ethanol and deionized water, and the prepared po...

Embodiment 2

[0060] 1. A method for preparing macroporous polymethyl methacrylate microsphere adsorbent by polymerization, characterized in that it is carried out according to the following steps:

[0061] (1) Preparation of monodisperse non-crosslinked polystyrene microspheres

[0062] 1.5g of polyvinylpyrrolidone powder was dissolved in the mixed solution of 95ml of absolute ethanol and 3ml of deionized water, and after being ultrasonically dispersed for 10 minutes, it was put into a three-necked flask equipped with nitrogen, a stirrer, and a condenser tube, and then mechanically Nitrogen was blown under stirring for half an hour. After fully removing the dissolved oxygen therein, add 25ml of styrene monomer dissolved in 0.2g of azobisisobutyronitrile under mechanical stirring, then react in a water bath at 70°C for 24 hours, and centrifuge to collect polystyrene particles after the reaction is complete. ball. The polystyrene microspheres were washed several times with a 1:3 solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com