Preparation method of diosmin

A technology of diosmin and hesperidin, which is applied in the field of pharmaceutical preparation, can solve the problems of serious environmental pollution, complicated reaction, difficult product-related impurities, etc., and achieves the effects of serious environmental pollution, high product purity and great cost advantage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

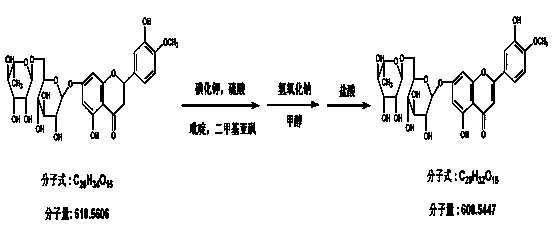

Method used

Image

Examples

Embodiment 1

[0023] Add 200 milliliters of pyridine and 200 milliliters of dimethyl sulfoxide into the reflux reactor, add 100 grams of hesperidin after mixing, then add 0.3 grams of potassium iodide and 5 milliliters of sulfuric acid, heat and reflux for 6 hours, recover the organic solvent under reduced pressure, and concentrate to Thick paste, then add 500 ml of 50% (volume percentage) methanol solution containing 1.2 mol / L sodium hydroxide, heat to 50 ° C, stir to dissolve completely, filter with filter paper to remove insoluble impurities, and add hydrochloric acid to the filtrate to acidify The pH value was 5, and the crystallization was allowed to stand for 3 hours. The crystals were collected, washed with water and dried to obtain 87 g of diosmin.

Embodiment 2

[0025] Add 200 milliliters of pyridine and 200 milliliters of dimethyl sulfoxide into the reflux reaction kettle, add 100 grams of hesperidin after mixing, then add 0.5 grams of potassium iodide, 5 milliliters of sulfuric acid, heat and reflux for 5 hours, recover the solvent under reduced pressure, concentrate to thick paste, then add 500 ml of 50% methanol solution containing sodium hydroxide 1.2mol / L, heat to 50°C, stir to dissolve completely, filter with filter paper to remove insoluble impurities, add hydrochloric acid to the filtrate to acidify to pH 5, and let it stand After crystallization for 3 hours, the crystals were collected, washed with water and dried to obtain 88 g of diosmin.

Embodiment 3

[0027] Add 250 milliliters of pyridine and 250 milliliters of dimethyl sulfoxide in the reflux reactor, add 100 grams of hesperidin after mixing, then add 0.8 grams of potassium iodide, 5 milliliters of sulfuric acid, heat and reflux for 4 hours, recover the organic solvent under reduced pressure, and concentrate to Thick cream, then add 500 ml of 60% methanol solution containing sodium hydroxide 1.2mol / L, heat to 50°C, stir to dissolve completely, filter with filter paper to remove insoluble impurities, add hydrochloric acid to the filtrate to pH 6, static The crystallization was carried out for 3 hours, the crystals were collected, washed with water and dried to obtain 90 g of diosmin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com