Metallurgical Process of Tungsten Mineral Raw Materials with Multiple Closed Cycles

A mineral raw material and process technology, applied in the field of tungsten smelting, can solve the problems of no circulation, high production cost, difficult continuous production, etc., and achieve the effects of reducing energy consumption and cost, reducing processing costs, and being easy for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

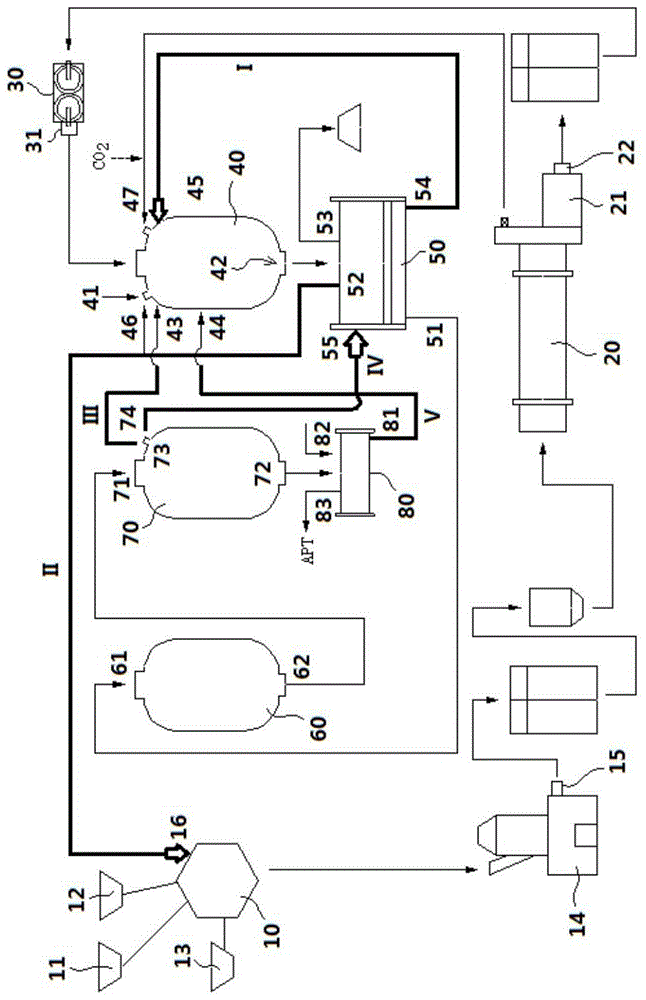

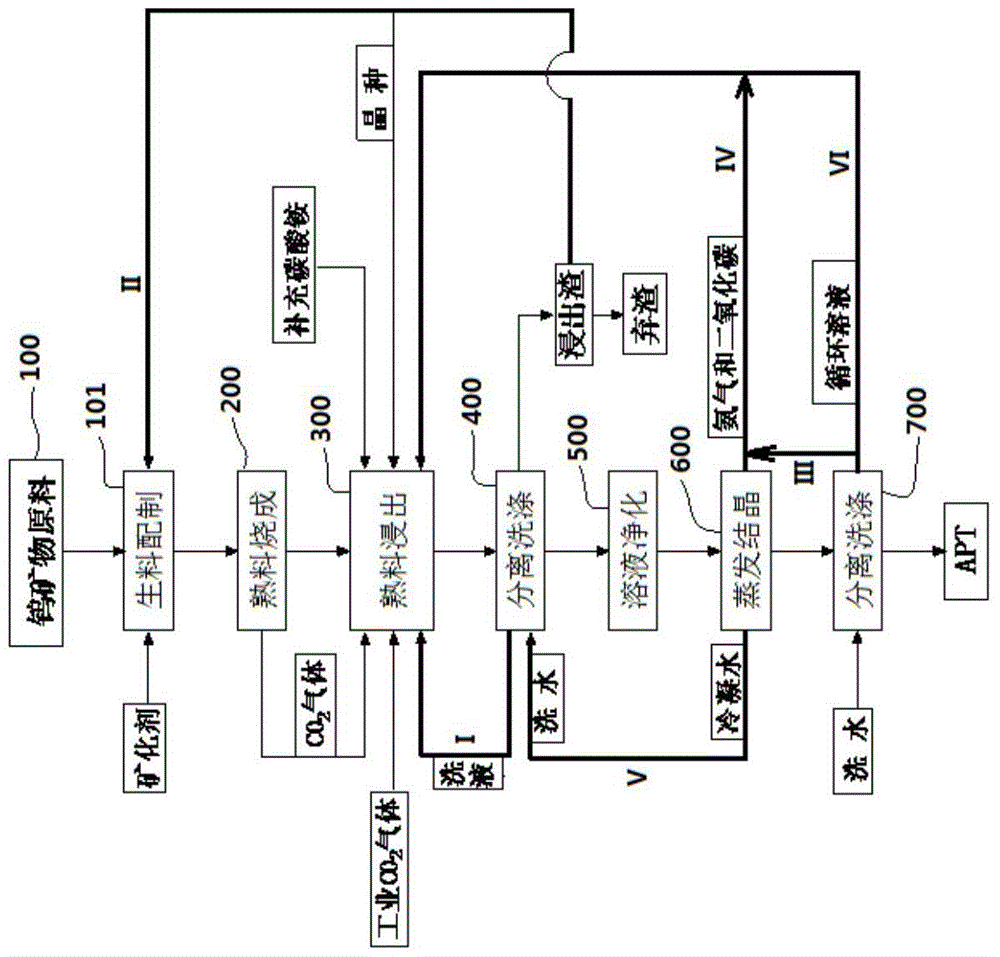

Method used

Image

Examples

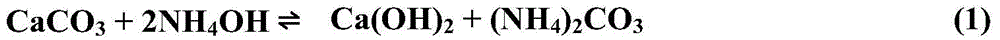

Embodiment 1

[0104] Embodiment 1: by CaO / WO 3 Molecular ratio is 3.3, a certain scheelite (WO 3 The mass percentage content is 49.53%, the Fe mass percentage content is 0.43%) and clinker leaching residue (the main component is CaCO 3 ) and mineralizer calcium fluoride are ground and mixed to obtain the raw meal, the addition of calcium fluoride is 5.2% (mass percentage) of the dry tungsten mineral raw material amount, and the particle size of the raw meal is ≤40 μm. Then, in the roasting furnace In the air atmosphere, the clinker was obtained by roasting at 800°C for 2.0h. After the clinker is cooled to room temperature, it is ground with a vibrating mill, and the clinker particle size is ≤45 μm. Weigh 5.0g of finely ground clinker and add it to the reaction kettle with ventilation and mechanical stirring device, and add 50g-(NH 4 ) 2 CO 3 / 100g-H 2 O ammonium carbonate solution 50mL and sealed, and then into CO 2 gas, control the absolute pressure of the reaction system to 2atm, a...

Embodiment 2

[0105] Embodiment 2: by (CaO+FeO) / WO 3 Molecular ratio is 4.5, a black and white tungsten mixed ore (WO 3 The mass percent content is 63.75%, the Fe mass percent content is 5.90%) and the clinker leaching slag are ground and mixed to obtain raw meal, the raw meal particle size is ≤45μm, and then, in the shaft furnace, the weak reducing atmosphere At 950°C for 3.0 hours, clinker was obtained. After the clinker is cooled to room temperature, it is ground with a ball mill, and the particle size of the clinker is ≤45 μm. Take by weighing 20.0g clinker and join in the reaction kettle of band ventilation and mechanical stirring device, add 35g-(NH 4 ) 2 CO 3 / 100g-H 2 O ammonium carbonate solution 100mL and sealed, and then into CO 2 Gas, control the absolute pressure of the reaction system to 2atm, and react at 70°C for 4h. After the reaction, the leached pulp is vacuum filtered, and the filter cake is washed three times with pure water. The leaching rate of tungsten in cli...

Embodiment 3

[0106] Embodiment 3: press (CaO+FeO+MnO) / WO 3 Molecular ratio is 3.4, a wolframite (WO 3 The mass percentage content is 62.40%, the Fe mass percentage content is 14.08%, the Mn mass percentage content is 2.25%) and the clinker leaching residue and calcium fluoride are ground and mixed to obtain the raw meal, and the calcium fluoride The amount of addition is 7% (mass percentage) of the dry tungsten mineral raw material, and the particle size of the raw material is ≤40 μm. Then, in a tubular roaster, under a neutral atmosphere, roast at 800°C for 6.0 hours to obtain clinker, and the clinker is cooled After reaching room temperature, use a rod mill to grind finely, the clinker particle size is ≤45μm; the leaching equipment selects a ball mill leaching device with a built-in ammonium carbonate saturated solution, and adds ammonium bicarbonate according to 1.0 times the theoretical amount; put the clinker into the leaching equipment, Reaction at 80°C for 4h. After the reaction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com