Method for manufacturing asymmetric super capacitor

A technology for supercapacitors and manufacturing methods, which is applied in the manufacture of hybrid/electric double-layer capacitors, double-layer capacitors, electrolytic capacitors, etc., can solve problems such as poor dispersion of defects and poor conductivity, and achieve improved purity and utilization, improved stability, The effect of ultra-high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

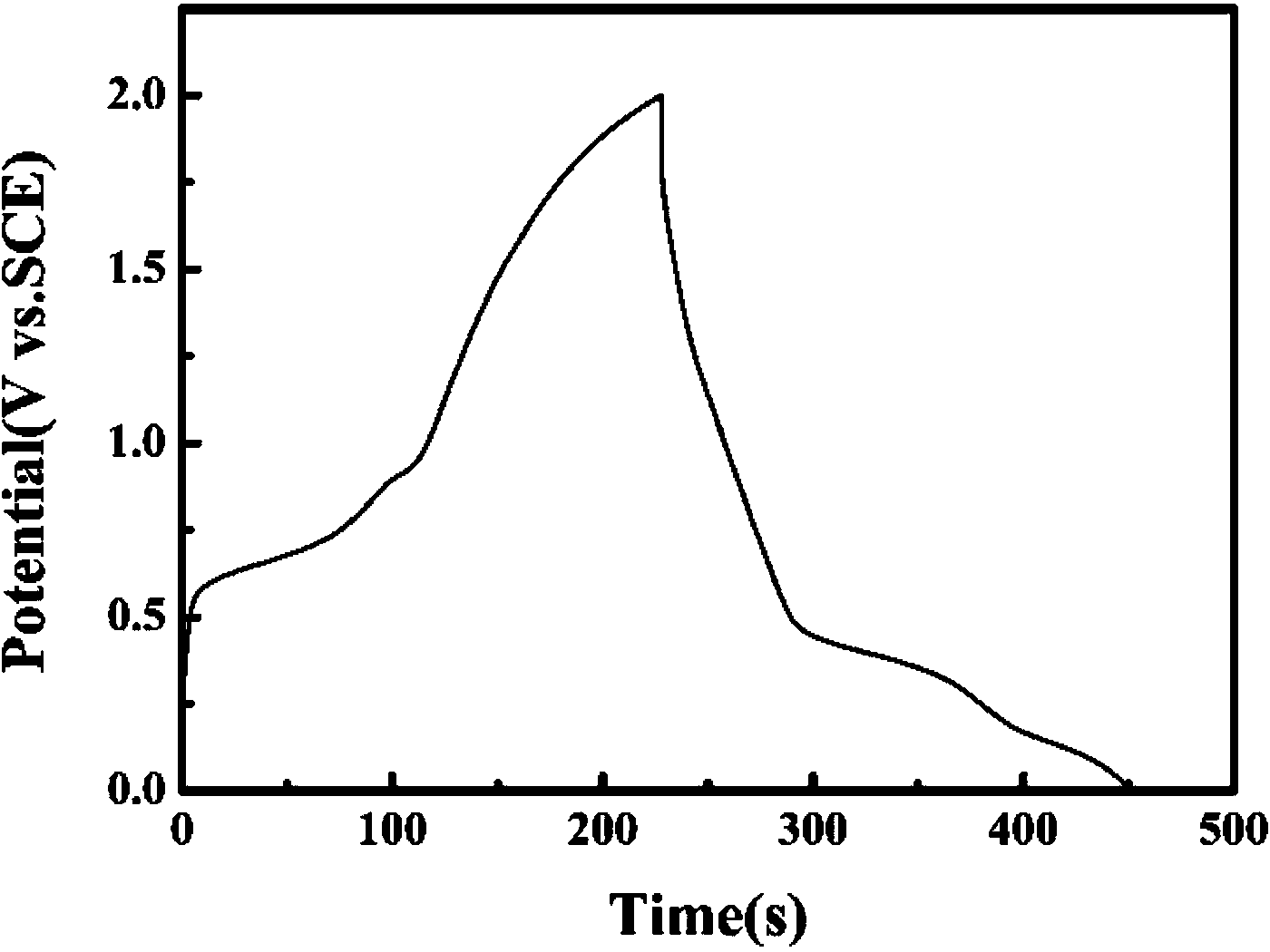

[0044] The invention provides a method for preparing a supercapacitor with high energy density, high power density and long cycle life. First, the electrode material graphene and cobalt hydroxide are compounded by plasma enhanced chemical vapor deposition method and electrochemical deposition method, and cobalt hydroxide / graphene is used as the positive electrode material, potassium hydroxide / potassium ferricyanide mixed aqueous solution The positive electrode system is composed of the positive electrolyte; then the activated carbon electrode is prepared by spraying / scraping method, and the negative electrode is composed of activated carbon / carbon paper as the negative electrode material and potassium hydroxide / p-phenylenediamine mixed aqueous solution as the negative electrolyte system; the two-electrode system is connected through a selectively permeable membrane, so that the two electrodes can function independently, and then electrochemically test the new capacitor, the spe...

Embodiment 1

[0072] 1) Using PECVD equipment, heat up the metal base material in argon, with a flow rate of 20 sccm, a pressure of 200 Pa, a deposition temperature of 800° C., and a heating rate of 20° C. / min.

[0073] 2) When the temperature reaches the reaction temperature of 800°C, methane gas is introduced, and the gas ratio is CH 4 / Ar=20 / 80, the gas pressure is 400Pa.

[0074] 3) Turn on the RF power supply, the RF power is 200W, and the ionization time is 30min.

[0075] 4) After the reaction is over, continue to pass argon to room temperature, and take it out for use in the next step.

[0076] 5) The constant temperature water bath is maintained at a constant temperature of 45°C. Adjust the deposition potential to -0.9V, and perform electrochemical deposition in the three-electrode system according to the predetermined deposition amount in the experiment; after the electrolysis, turn off the constant voltage and constant current power supply, take out the working electrode, wash ...

Embodiment 2

[0082] Change the new mixed electrolyte in step 7) of Example 1 to the traditional potassium hydroxide electrolyte (that is, without the addition of potassium ferricyanide and p-phenylenediamine). Under constant current charge and discharge at a current density of 2A / g, the specific capacitance of the capacitor is 54.0F / g, the highest energy density is 16.9Wh / kg, and the corresponding power density is 1500W / kg.

[0083] According to the example of the above-mentioned invention, high-performance positive electrode system with cobalt hydroxide / graphene-potassium hydroxide / potassium ferricyanide and negative electrode system with activated carbon / carbon paper-potassium hydroxide / p-phenylenediamine can be prepared. A new type of asymmetric capacitor with an electrode system, the new type of asymmetric capacitor has the following characteristics:

[0084] 1) Graphene provides high specific surface area and high electrical conductivity, good stability, favorable electron transport, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com