Coating agent, decorative film and molded body

A coating agent and monomer technology, applied in the field of decorative films, molded bodies, and coating agents, can solve problems such as difficulty in showing adhesion, and achieve excellent adhesion, high adhesion, and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

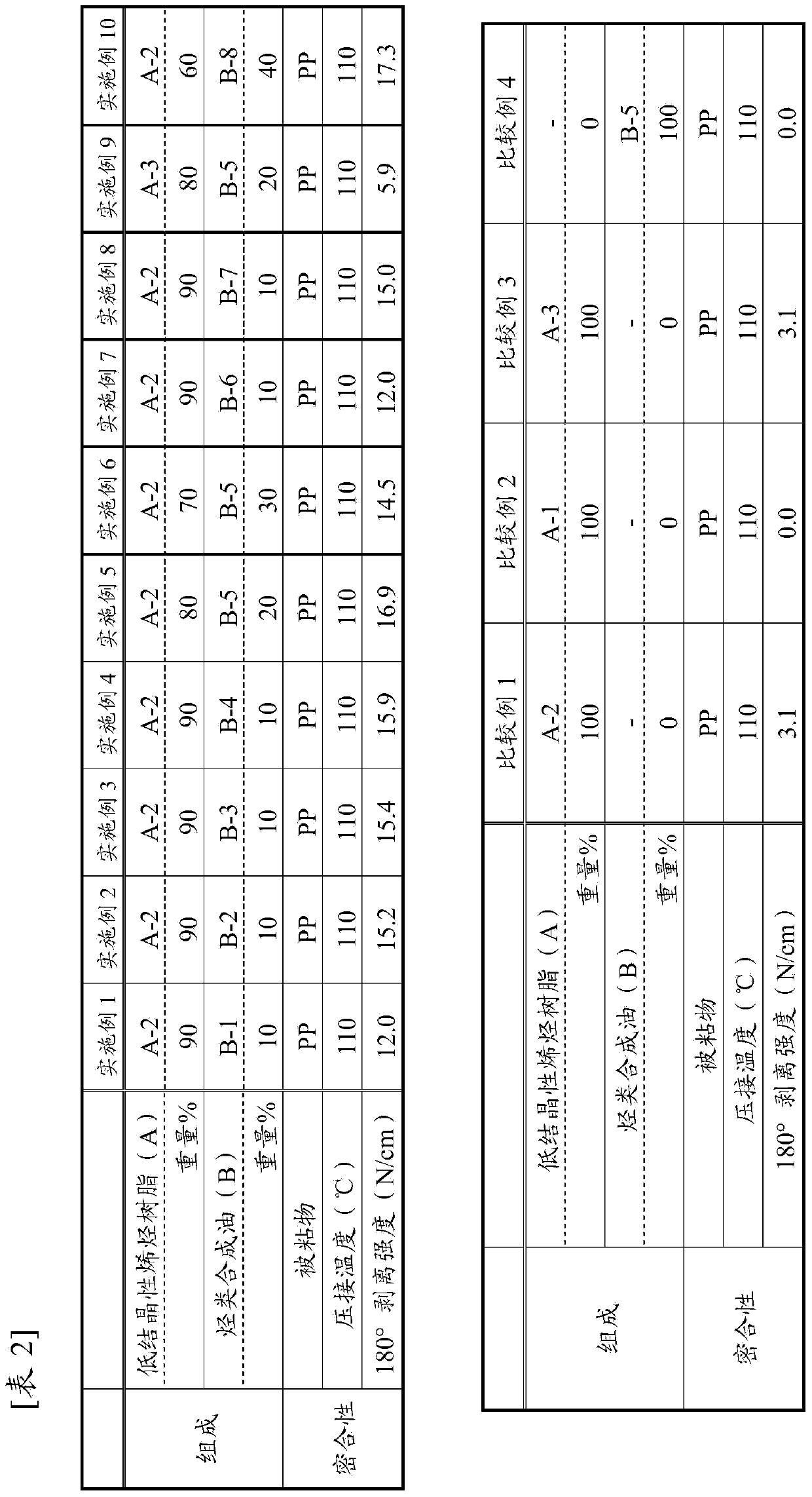

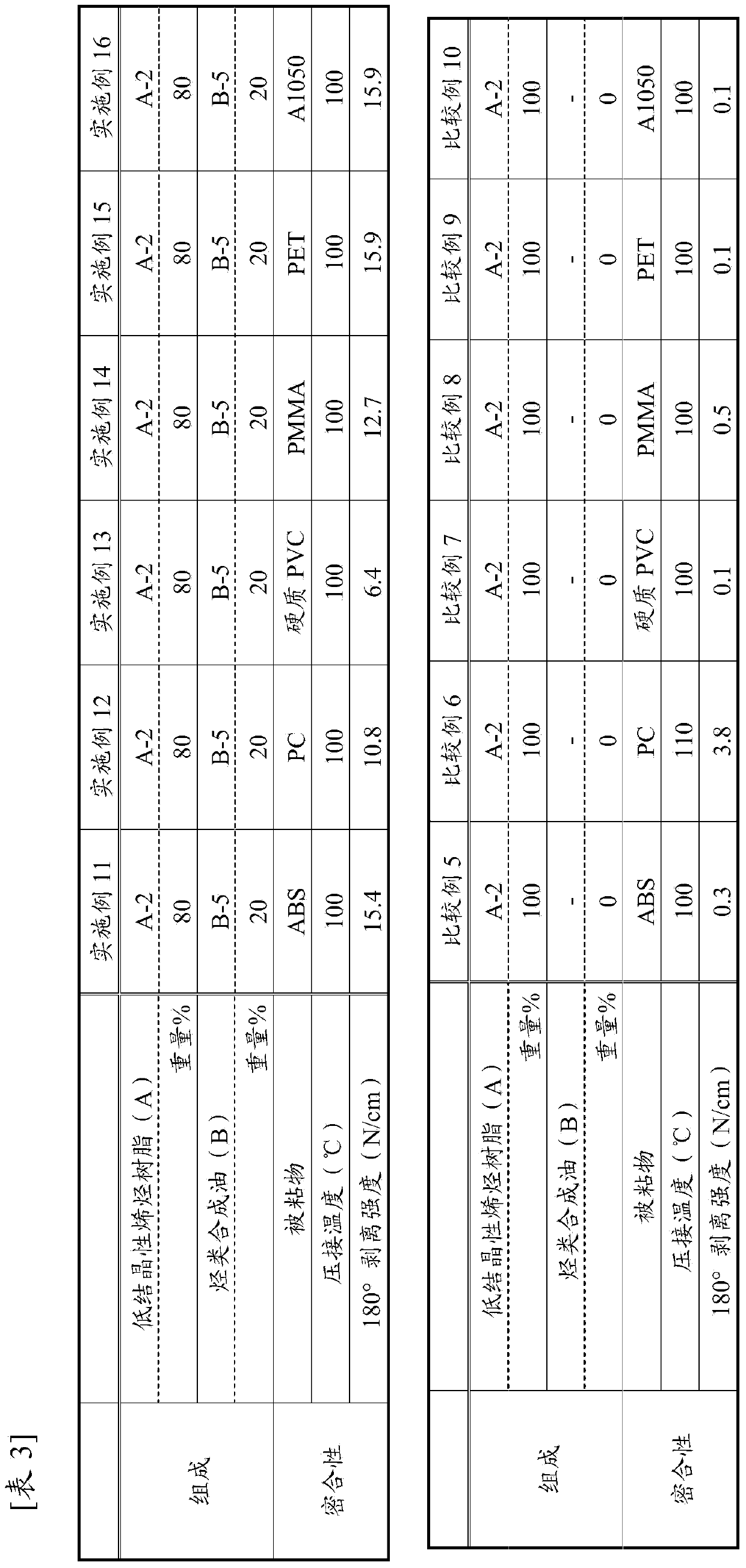

Examples

Embodiment

[0172] (Determination of propylene content and ethylene content)

[0173] use 13 Calculated by C-NMR.

[0174] (Measurement of melting point and enthalpy of fusion)

[0175] The melting point and the melting enthalpy were determined using a differential scanning calorimeter (manufactured by TA Instruments; DSC-Q1000). During the process of raising the temperature from 30°C to 180°C at 10°C / min, then cooling down to 0°C at 10°C / min, and then raising the temperature to 150°C at 10°C / min, use the thermogram during the second heating , according to JIS K 7122, the melting point and melting enthalpy were obtained.

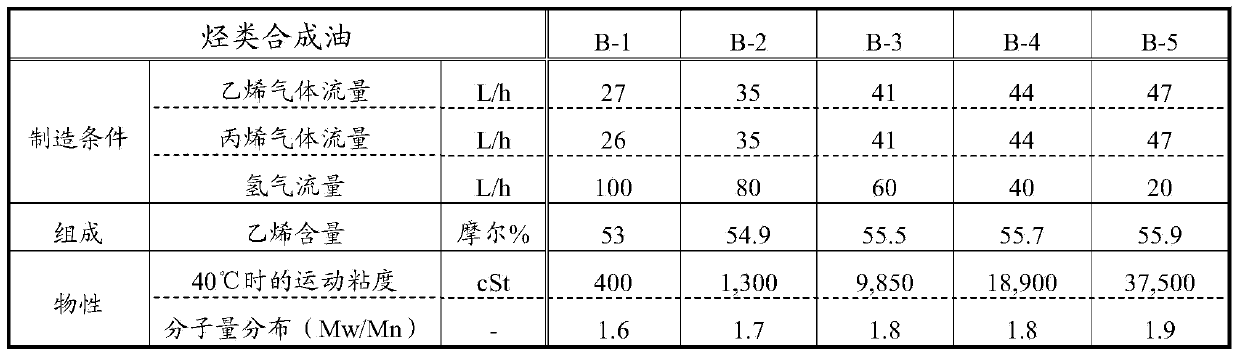

[0176] (Measurement of Kinematic Viscosity at 40°C)

[0177] Measured based on ASTM D 445.

[0178] (Measurement of weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn))

[0179] Using gel permeation chromatography (manufactured by Shimadzu Corporation; LC-10 series), the molecular weight and molecular weight distribution of the olefin-base...

manufacture example 1-1

[0195] [Production Example 1-1: Synthesis of Propylene / 1-Butene Copolymer]

[0196] Into a 2-liter autoclave fully replaced with nitrogen, 900 ml of hexane and 90 g of 1-butene were charged, 1 mmol of triisobutylaluminum was added, the temperature was raised to 70° C., and then propylene was supplied so that the total pressure was 7kg / cm 2 G, add 0.30 mmol of methyl aluminoxane, and add racemic-dimethylsilylene-bis{1-(2-methyl-4-phenyl) in an amount of 0.001 mmol converted to Zr atoms Indenyl)} zirconium dichloride, continuously supplying propylene while keeping the total pressure at 7kg / cm 2 G side was polymerized for 30 minutes. After the polymerization, degassing was performed, and the polymer was recovered in a large amount of methanol, and dried under reduced pressure at 110° C. for 12 hours. The obtained propylene / 1-butene copolymer (low crystalline olefin resin A-1) had a melting point of 78.3° C., a melting enthalpy of 29.2 J / g, a Mw of 330,000, and a propylene cont...

manufacture example 1-2

[0197] [Production Example 1-2: Synthesis of maleic anhydride-modified propylene / 1-butene copolymer]

[0198] 3 kg of the above-mentioned propylene / 1-butene copolymer (low crystalline olefin resin A-1) was added to 10 L of toluene, and the temperature was raised to 145° C. under a nitrogen atmosphere, and the copolymer was dissolved in toluene. Furthermore, 382 g of maleic anhydride and 175 g of di-tert-butyl peroxide were supplied to the system over 4 hours with stirring, followed by stirring at 145° C. for 2 hours. After cooling, a large amount of acetone was added to precipitate the modified copolymer, which was filtered, washed with acetone, and vacuum-dried.

[0199] The obtained maleic anhydride-modified propylene / 1-butene copolymer (low crystalline olefin resin A-2) had a melting point of 75.8°C, a melting enthalpy of 28.6 J / g, and a Mw of 110,000. The grafting of maleic anhydride The amount is 1 part by weight with respect to 100 parts by weight of the modified copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com