High-strength polyethylene cable jacket material and preparation method thereof

A technology of high-strength polyethylene and cable sheathing material, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem that the mechanical strength cannot meet the market demand, etc., and achieve good mechanical properties, high tensile strength, and good fatigue resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

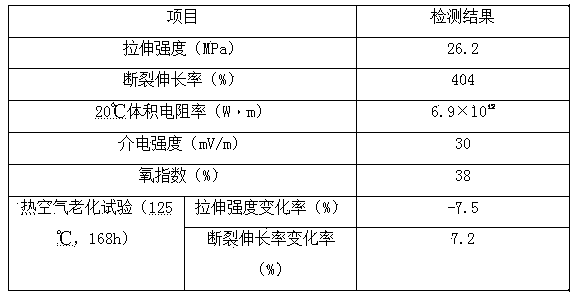

Examples

Embodiment

[0012] A high-strength polyethylene cable sheathing material, made of the following raw materials by weight (kg): linear low-density polyethylene 46, polytrimethylene terephthalate 32, polychlorotrifluoroethylene 22, 2-ethylhexyl Cadmium Acid 2.5, Propylene Glycol Dibenzoate 8, Hydrated Magnesium Silicate Superfine Powder 16, 3,5-Di-tert-butyl-4-Hydroxybenzoic Acid Hexadecyl 1.5, Pentaerythritol Tetrabenzoate 12 , barium laurate 2.5, glyceryl tributyrate 6, potassium titanate whiskers 12, 1,4-dithiothreitol 2.5, vitamin C palmitate 2, butyl methoxydibenzoyl methane 4, inhibitor Combustion agent 16, zirconium dioxide 12, 1,1'-thiobis(2-naphthol) 1.5;

[0013] The preparation method of the flame retardant is as follows: a, weigh boehmite, brucite, and montmorillonite in a ratio of 7:4:3 by mass, mix them evenly, pulverize them, pass through a 150-mesh sieve, and then add water to make an oar Concentration is 55% slurry, then add 4.5% ZnO, 25% NaOH and 20% Na 2 Sn(OH) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com