Dry-wet spinning process for agar fiber

A dry-wet spinning and agarose technology, which is applied in the field of fiber spinning, can solve the problems of low fiber mechanical strength, high workshop requirements, and difficult industrialization, so as to enhance mechanical strength, avoid safety hazards, and protect the environment. The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: dry-wet spinning

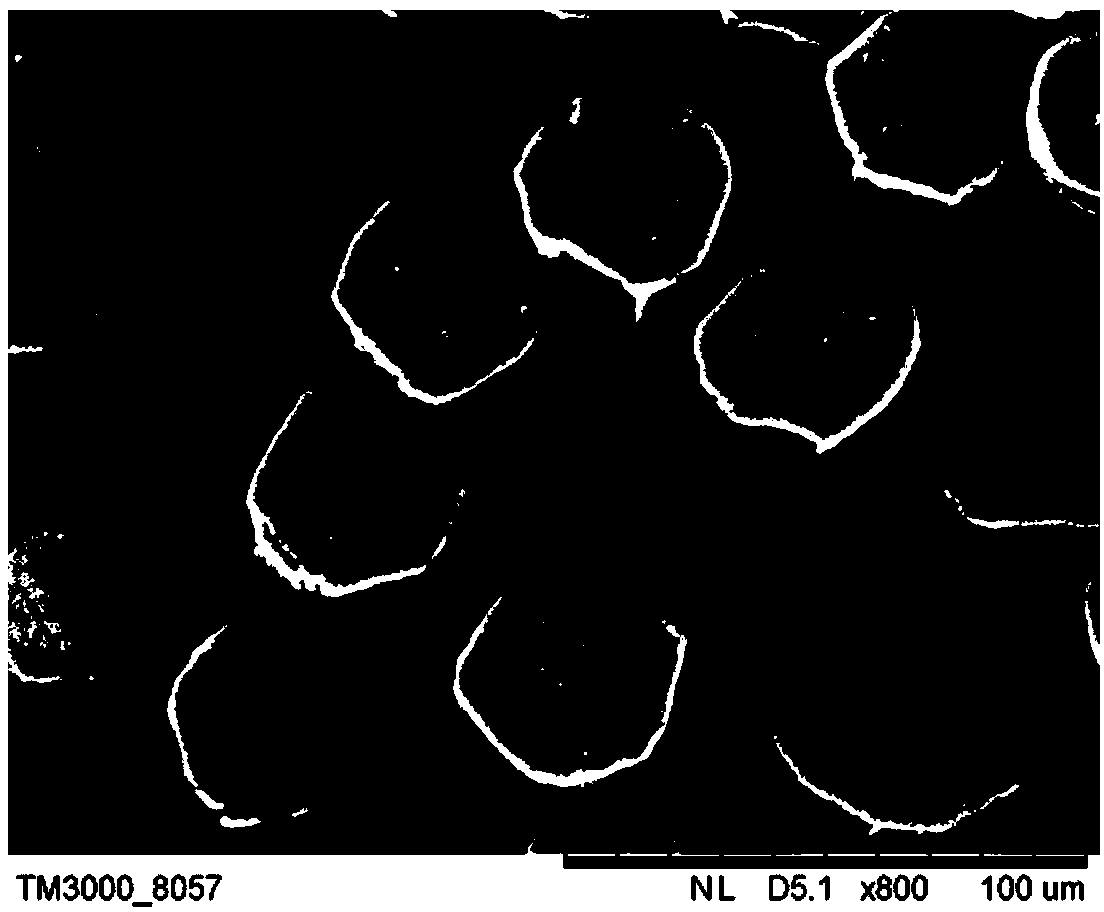

[0028] Add 120 grams of agar to 1080 grams of DMSO, stir and dissolve at 80°C to obtain an agar solution with a content of 10% (mass percentage), filter, defoam and stand for 8 hours to make a spinning solution, and filter the above The degassed spinning solution is gelled through the air layer (the length of the air layer is 5mm) through the dry-wet spinning machine; the gelled stream enters the coagulation bath for coagulation and drawing, the coagulation bath is water, and the coagulation bath temperature At room temperature, the stretching ratio of the fiber is 1.1, the fiber is soaked in oil agent (silicone oil content 0.1% (v / v)) for 4 hours, washed, dehydrated with ethanol, and dried to obtain the fiber material. Its scanning electron microscope picture is as image 3 , 4 As shown, it can be seen from the figure that the dry-wet spun fibers are thinner and the fiber interior is denser.

Embodiment 2

[0029] Embodiment 2: dry-wet spinning

[0030] Add 60 grams of agar to 440 grams of DMF, fully stir and dissolve at 80 ° C to obtain an agar solution with a content of 12% (mass percentage), filter, defoam and stand for 6 hours to make a spinning solution. The spinning solution after filtering and degassing is gelled through the air layer (the length of the air layer is 10mm) through the dry-wet spinning machine; the gelled stream enters the coagulation bath for coagulation and drawing, the coagulation bath is water, The temperature is 30°C, the draft ratio of the fiber is 1.2, the fiber is soaked in oil agent (amino silicone oil content 0.1% (v / v)) for 4 hours, washed, dehydrated with ethanol, washed, and dried to obtain the fiber material.

Embodiment 3

[0031] Embodiment 3: dry-wet spinning

[0032] Add 70 grams of agar gel into 430 grams of DMSO, fully stir and dissolve at 80°C to obtain an agar solution with a content of 14%, filter, defoam and stand for 6 hours to make a spinning solution, and filter and defoam the above The spinning solution is gelled through the air layer (the length of the air layer is 12mm) through the dry-wet spinning machine; the gelled stream enters the coagulation bath for coagulation and drawing, the coagulation bath is water, and the temperature of the coagulation bath is 10°C. The draft ratio of the fiber is 1.2, and the fiber is soaked in an oil agent (0.05% (v / v) of dimethyl silicone oil) for 10 hours, washed, dehydrated with ethanol, washed, and dried to obtain a fiber material.

[0033] Comparative example 1, the agar fiber of embodiment 1,2,3 gained is carried out mechanical property test, and the result shows that the dry breaking strength of agar fiber reaches 1.6cN / dtex and 2.5cN / dtex,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com