Method for synthesizing trehalose under catalysis of co-immobilized double enzymes

A technology of trehalose and trehalose synthase, which is applied in the fields of immobilization on/in organic carriers, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of low utilization rate and high price of catalytic raw materials and substrates, and achieve The effect of reducing raw material costs, shortening production cycle, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

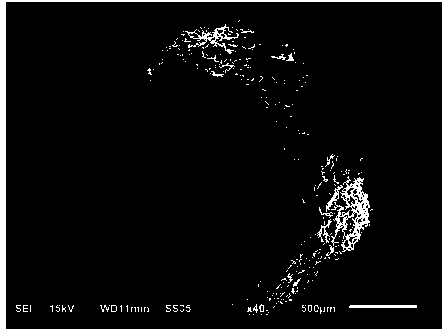

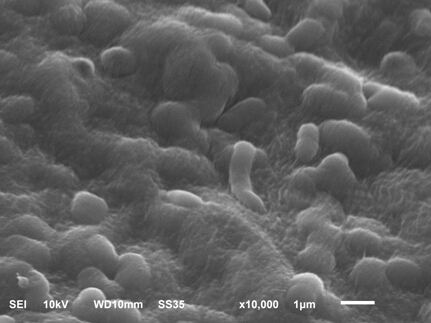

Image

Examples

Embodiment 1

[0038] This example illustrates the source of strains.

[0039] The strain used in this patent is Escherichia coli derived from the trehalose synthase gene of Thermus thermophilus ATCC 33923 (Gene Bank: AQOS01000003) saline-alkali soil metagenomes (Saline-Alkali Soil Metagenomes). Using the document "Ling Jiang, Ming Lin, Yang Zhang et al. Identification and Characterization of a Novel Trehalose Synthase Gene Derived from Saline-Alkali Soil Metagenomes. Pols One 8(10): e77437. doi previously published by the inventor of the present application : 10.1371 / journal.pone.0077437." The method described in, the bacterial strain number that component obtains is BL21-treS.

[0040] At the same time, the applicant hereby declares that within 20 years from the date of patent application, the starting bacterial strain described in the present invention will be provided free of charge to the public.

Embodiment 2

[0042] This example illustrates the specific synthesis steps and synthesis effects of catalytic synthesis of trehalose.

[0043] The BL21-treS strain obtained in Example 1 was used for trehalose synthesis catalysis.

[0044] The high-temperature resistant α-amylase and β-amylase used in this example were all purchased from Aladdin Company with a purity of 93%-96%.

[0045] Firstly, the genetic engineering bacteria of Escherichia coli were cultivated on the solid LB medium with ampicillin by streaking method to obtain single colonies of Escherichia coli. The formula of the solid medium with ampicillin was: peptone 10 g / L, yeast powder 5 g / L, sodium chloride 10 g / L, ampicillin antibiotic 0.1 g / L, agar 20 g / L. The specific operation process is to prepare the medium according to the requirements, sterilize the prepared culture at 121°C for 30 minutes, pour it on the plate after cooling, inoculate with the streaking method, and culture in a constant temperature incubator to obtain...

Embodiment 3

[0060] This example illustrates the effect of using pullulanase instead of β-amylase to catalyze the synthesis of trehalose from starch hydrolyzate after dual enzyme immobilization.

[0061] The pullulanase used in this example was purchased from Aladdin with a purity of 93%-96%.

[0062] According to the method described in Example 2, the method for synthesizing trehalose by co-immobilization of double enzymes to catalyze starch hydrolyzate is different in that:

[0063] Its step (6) replaces β-amylase with pullulanase to catalyze the synthesis of trehalose from starch hydrolyzate after double-enzyme immobilization

[0064] After testing, the initial conversion rate was 64.9%, the conversion rate was 63.2% after the dual-enzyme-immobilized microspheres were reused 8 times, and the conversion rate was 60% after the dual-enzyme-immobilized microspheres were reused 16 times, with an average conversion time of 23h, and the process of repeated production 16 times was not contamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com