NaX zeolite molecular sieve and preparation method thereof

A technology of zeolite molecular sieve and dispersant, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

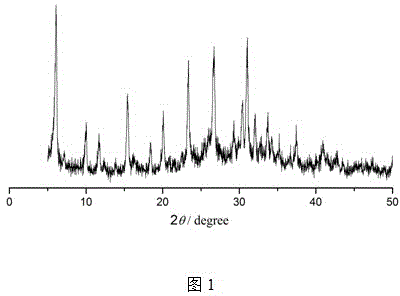

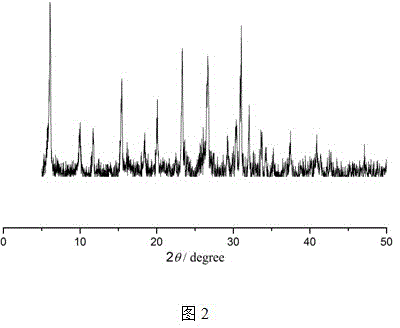

Image

Examples

Embodiment 1

[0028] (1) Add 1771 g spent catalyst fine powder, 276 g diatomaceous earth, 206 ml water glass, and 40 g sodium hydroxide, add water and stir evenly to make a slurry with a solid content of 50% by weight, and spray it to make a particle size concentrated in Microspheres of 0-150 μm were calcined at 1000 °C for 0.5 hours to obtain calcined microspheres;

[0029] (2) Add water to the roasted material obtained in step (1) and stir evenly to make a slurry, adjust the final pH value of the slurry to 3.0 with a mixture of 8 wt% tartaric acid and citric acid, raise the temperature to 90 °C, and react for 10 minutes. Afterwards, the mother liquor is removed by filtration, and the modified material is obtained by washing and filtering;

[0030] (3) Put 234 ml of sodium hydroxide, 53 ml of water glass water, 159 ml of water glass, and 200 g of modified materials into a stainless steel crystallization reaction kettle in a stirring state, raise the temperature to 120 ℃, and crystallize at...

Embodiment 2

[0033] (1) Add 852 g of spent catalyst, 497 g of diatomaceous earth, 48 g of sodium cellulose, 36 g of sodium carbonate, 125 ml of water glass, add water, grind in a ball mill for 2 h, and press into tablets on a tablet machine. The material is put into a muffle furnace and roasted at 700° C. for 10 hours to obtain a roasted material;

[0034] (2) Add water to the roasted material obtained in step (1), adjust the pH value of the end point of the system to 5.0 with 10% by weight tartaric acid, raise the temperature to 30 ° C, and react for 60 minutes. After the reaction is completed, filter to remove the mother liquor, wash and filter to obtain the modified material ;

[0035] (3) Put 417 ml of sodium hydroxide, 163 ml of water, and 100 g of modified materials into a stainless steel crystallization reaction kettle in turn under stirring, raise the temperature to 50 °C, and crystallize at a constant temperature for 40 hours. After the crystallization is completed, the mother li...

Embodiment 3

[0038] (1) Add water to 2438 g of spent catalyst, 621 g of diatomite, 217 ml of water glass, 90 g of potassium hydroxide, and 60 g of polyacrylamide, grind them in a ball mill for 2 hours, and extrude the strips on the extruder. Put the pellets into a muffle furnace, and roast them at 800°C for 4.5 hours to obtain a strip-shaped roasted material;

[0039] (2) Add water to the calcined material obtained in step (1), adjust the pH value of the end point of the system to 4.0 with 15 wt% nitric acid, raise the temperature to 60 °C, and react for 30 min. After the reaction is completed, filter to remove the mother liquor, wash and filter to obtain modified materials;

[0040] (3) Put 1522 ml of sodium hydroxide, 197 ml of water glass, 705 ml of water, and 500 g of modified materials into a stainless steel crystallization reaction kettle in turn under stirring, raise the temperature to 90 ℃, and crystallize at constant temperature for 10 hours. After the crystallization is completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com