Preparation method of 3, 5-dimethylphenol

A technology of dimethylphenol and isophorone, which is applied in the field of preparation of 3,5-dimethylphenol, can solve the problem of short life, unmentioned chromium-nickel alloy steel catalyst preparation method, tubular reactor material and tube diameter and other parameters, low yield and other problems, to achieve the effect of short reaction time, easy processing and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

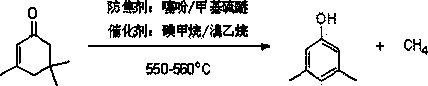

[0017] A kind of preparation method of 3,5-xylenol, adopts stainless steel tubular reactor, with isophorone as raw material, with halogenated aliphatic hydrocarbon as homogeneous catalyst, thiophene or dimethyl sulfide or its mixture is Anti-coking agent. The halogenated aliphatic hydrocarbon contains 1 to 6 carbon atoms, and the halogen can be iodine, chlorine and bromine. such as methyl iodide (CH 3 I), ethyl iodide (C 2 h 5 I) carbon tetrachloride (CCl 4 ), 1-bromobutane (CH 3 -CH 2 -CH 2 -CH 2 -Br), allyl bromide (CH 2 =CH-CH 2 Br), ethyl bromide (CH 3 -CH 2 Br) and dibromoethane (CH 2 Br-CH 2 Br) etc. The present invention preferably uses methyl iodide and ethyl bromide.

[0018] The aromatization dehydrogenation reaction of the isophorone of the present invention is carried out in a stainless steel tubular reactor with a total length of 80m and a DN32mm. The specific operation is as follows: add a certain amount of catalysts methyl iodide and ethyl bromid...

Embodiment 1

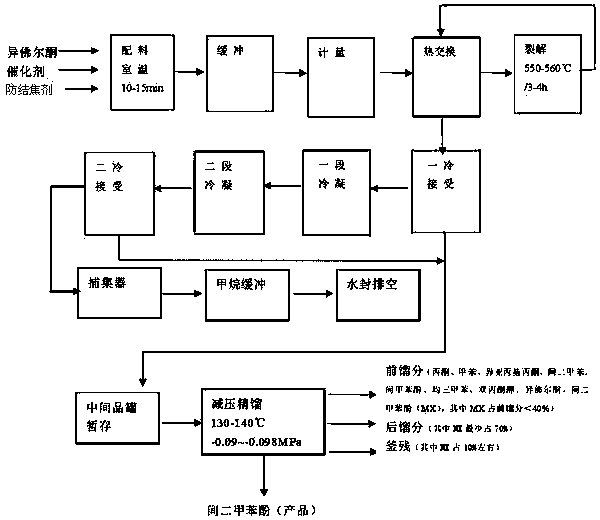

[0027] Example 1: Press figure 1 The route diagram for the preparation of 3,5-dimethylphenol (MX) is shown. Add 600 kg (4.35 kmol) of isophorone and 6 kg of homogeneous catalyst to the batching kettle, including 2 kg of methyl iodide, 4 kg of ethyl bromide, 3 kg of anti-coking agent dimethyl sulfide, mix and stir at room temperature for 10-15 min, the mixture flows into the stainless steel tubular reactor according to the feed flow rate of 150~200L / h, and is catalytically cracked at 550~560 ℃ for 3~4 hours. Under reduced pressure, 400 kg of the product was obtained by rectification under reduced pressure, the yield of 3,5-dimethylphenol (MX) was 75.6%, the conversion rate of isophorone was 98%, the selectivity of MX was 83.8%, and the content of MX was 98.5%.

Embodiment 2

[0028] Example 2: Proceed as shown in the roadmap for producing MX, add 600 kg (4.35 kmol) of isophorone (4.35 kmol) homogeneous catalyst 9 kg to the batching tank, including 3 kg of methyl iodide, 6 kg of ethyl bromide, and 3 kg of anti-coking agent thiophene kg, stirred at room temperature for 10-15 min, the mixture flowed into a stainless steel tubular reactor at a feed rate of 150-200 L / h, and was catalytically cracked at 550-560 °C for 3-4 h. Under the vacuum degree of -0.09~-0.098MPa, 420 kg of the product was obtained by rectification under reduced pressure, the yield of MX was 79.4%, the conversion rate of isophorone was 99%, the selectivity of MX was 85.3%, and the content of MX was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com