Dihalopyrazole amide and chlorfenapyr compound insecticidal composition

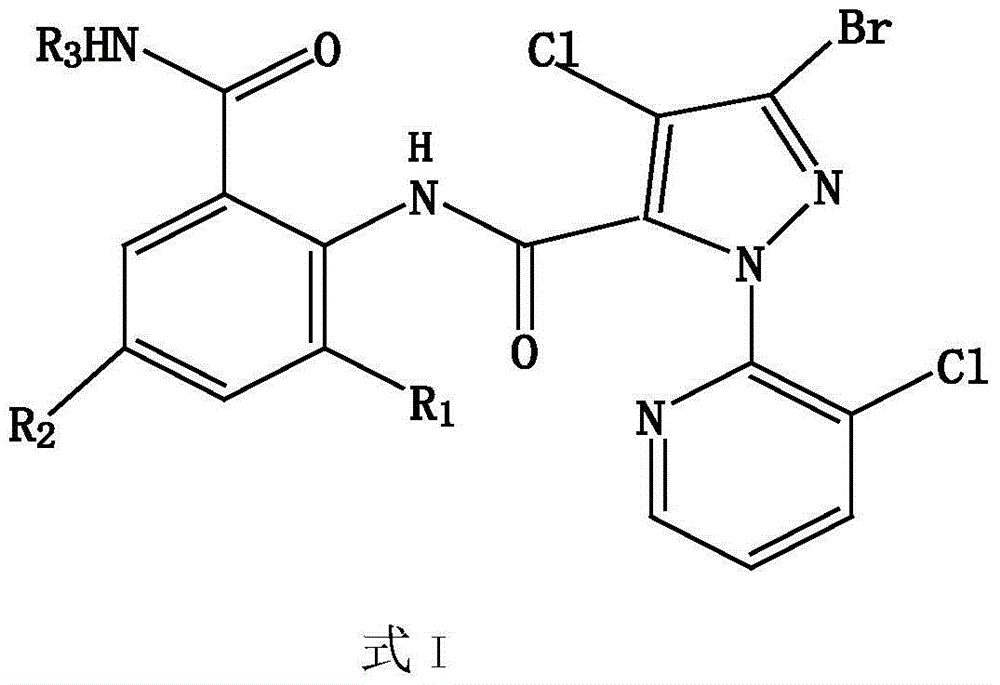

The technology of a dihalogenated pyrazole amide and an insecticidal composition is applied in the field of compound insecticidal compositions of dihalogenated pyrazole amide and chlorfenapyr, which can solve problems such as the generation of pest resistance, achieve improved efficacy, The effect of increasing the site of action and reducing the risk of phytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

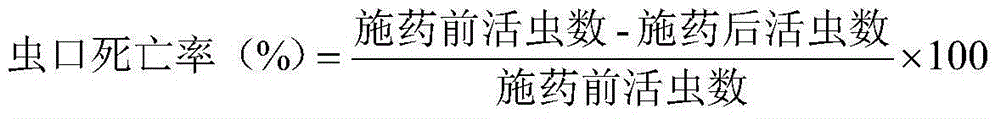

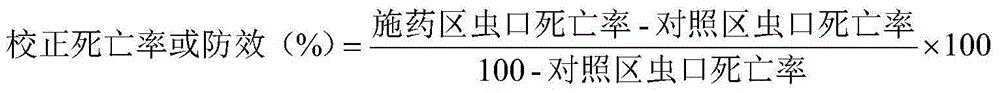

Examples

Embodiment 1

[0092] Example 1: (40% Dihalogenated Pyrazolamide · Chlorfenapyr Water Suspension Concentrate) 1:3

[0093] Components and content: dihalogenated pyrazole amide, 10%; chlorfenapyr, 30%; emulsifier Nongru NP, 10, 2%; dispersant polycarboxylate, 3%; thickener selected xanthan gum and magnesium aluminum silicate, the dosages are 0.1% and 1% respectively; antifreeze ethylene glycol, 3%; defoamer silicone compounds, 0.2%; water, the balance.

[0094] The preparation method of the above example 1 is: according to the components and weight percentages provided in the example, place dihalogenated pyrazole amide, chlorfenapyr, surfactant and other functional additives in the reaction kettle in sequence, add water Mix evenly, undergo high-speed shearing, wet sanding, and finally filter homogeneously to obtain the water-suspending agent. The main equipment is batching kettle, colloid mill or homogeneous mixer, sand mill.

Embodiment 2

[0095] Example 2: (50% dihalogenated pyrazole amide Chlorfenapyr water dispersible granule) 1:4

[0096] Components and content: dihalogenated pyrazole amide, 10%; chlorfenapyr, 40%; wetting agent sodium dodecyl sulfate, 4%; dispersant, alkylnaphthalene sulfonate formaldehyde condensate, 7%; filler Attapulgite, balance.

[0097] The preparation method of the above-mentioned Example 2 is: according to the components and their weight percentages provided in the example, the dihalogenated pyrazole amide, chlorfenapyr, dispersant, wetting agent and filler are mixed evenly, and after being pulverized by a jet mill Add 10-25% of water, knead, extrude, granulate, and dry to obtain water-dispersible granules. Or spray the pulverized powder with water in a boiling granulator, granulate, dry, and then sieve to obtain water-dispersible granules. The main equipments are mixer, jet mill, kneader, extrusion granulator, drying room or fluidized bed drying, or boiling granulator, screening ...

Embodiment 3

[0098] Example 3: (30% Dihalogenated Pyrazolamide Chlorfenapyr Oil Suspension Concentrate) 1:2

[0099] Components and content: dihalogenated pyrazole amide, 10%; chlorfenapyr, 20%; emulsifier Nongru BY-125, 7%; nonylphenol polyoxyethylene ether phosphate 8%; thickener selected organic Bentonite, the dosage is 1.3%; methyl oleate, the balance.

[0100] The preparation method of the above example 3 is as follows: according to the components and weight percentages provided in the example, place dihalogenated pyrazole amide, chlorfenapyr, surfactant and other functional additives in the reaction kettle in sequence, add oil The methyl ester is mixed evenly, subjected to high-speed shearing, wet sanding, and finally homogeneously filtered to obtain the oil suspending agent. The main equipment is batching kettle, colloid mill or homogeneous mixer, sand mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com