Titanate nanosheet photocatalytic membrane material, as well as preparation method and application thereof

A photocatalytic film and nanosheet technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of a wide range of applications, high transparency, good recycling performance and reuse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 3.22g of anhydrous potassium carbonate (commercially available), 0.55g of anhydrous lithium carbonate (commercially available), and 7.68g of titanium oxide (commercially available) and mix and grind for 1 hour, then calcinate at 1000°C for 20 hours to obtain a 10g alkali metal layer Titanate K 0.8 Ti 1.73 Li 0.27 o 4 ;

[0028] Weigh 2.3g of the above-mentioned alkali metal layered titanate K 0.8 Ti 1.73 Li 0.27 o 4 , impregnated in 200mL with a concentration of 1mol L -1 Hydrochloric acid aqueous solution, replace the aqueous hydrochloric acid solution once a day, filter and wash after three days, and obtain 2 g of layered protonated titanate H after drying at 25 ° C 1.07 Ti 1.73 o 4 ·H 2 O;

[0029] Weigh 1 g of the above layered protonated titanate H 1.07 Ti 1.73 o 4 ·H 2 O, immersed in 250 mL of water, adding 0.6 mL of commercially available ethylamine aqueous solution containing 0.408 g of ethylamine, and mechanically shaking for 24 hours to o...

Embodiment 2

[0031] (1) The sol containing 40 mg titanate nanosheets prepared in Example 1 is added to a filter equipped with a microporous membrane (5 cm in diameter, and the pore size of the microporous membrane is 0.45 micron);

[0032] (2) Under reduced pressure, the titanate nanosheets are suction-filtered to form a titanate nanosheet film;

[0033] (3) Soak the titanate nanosheet membrane obtained in step (2) with 0.1mol / L hydrochloric acid aqueous solution, wash with deionized water, dry at room temperature 25°C for 24 hours, and finally remove it from the microporous membrane to obtain a transparent , flexible, unsupported photocatalytic film, that is, titanate nanosheet photocatalytic film material.

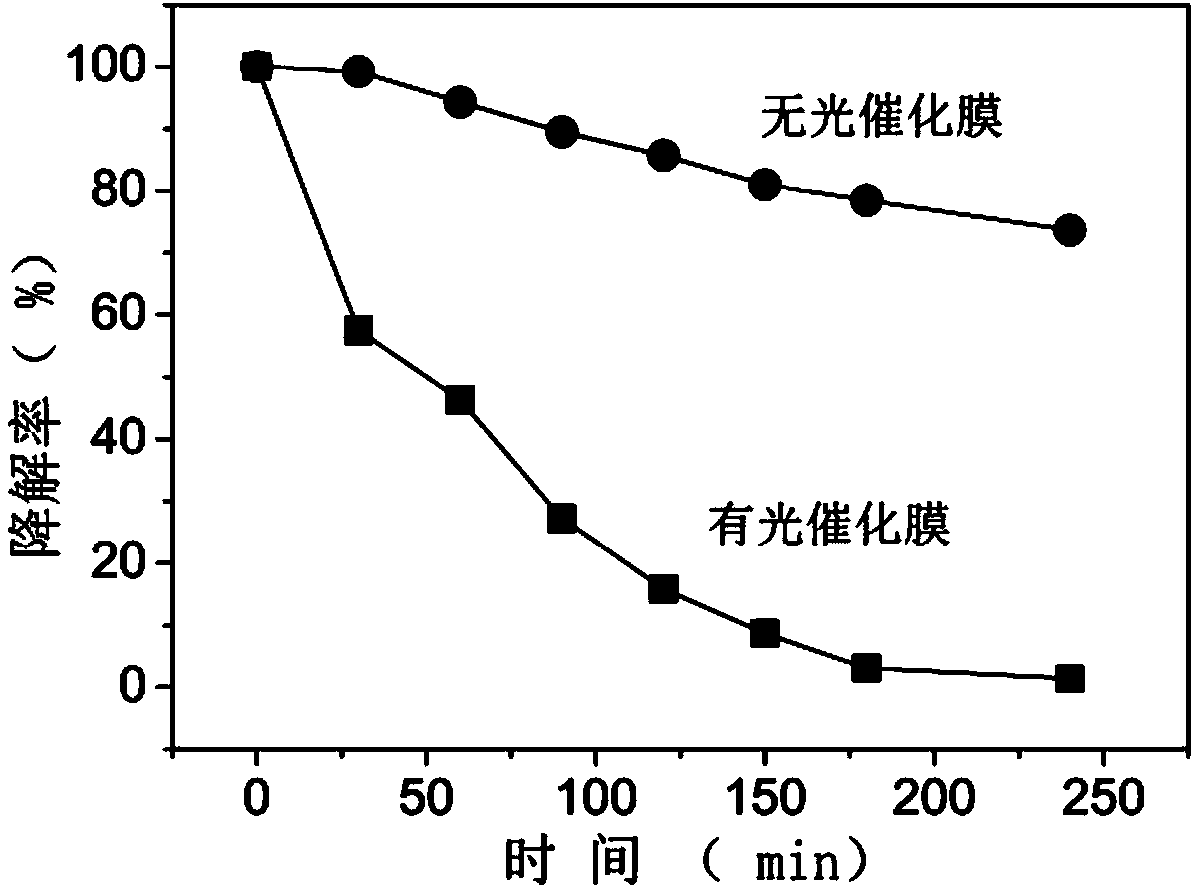

[0034] Such as figure 1 Shown is the titanate nanosheet photocatalytic film material prepared in Example 2, which is a transparent, flexible, unsupported photocatalytic film.

Embodiment 3

[0036] (1) Add the sol containing 40mg titanate nanosheets prepared in Example 1 into a petri dish (5 cm in diameter);

[0037] (2) Carry out solvent evaporation at room temperature 25 ℃, form titanate nanosheet film;

[0038](3) Soak the titanate nanosheet film obtained in step (2) with 0.1mol / L hydrochloric acid aqueous solution, wash with deionized water, dry at room temperature 25°C for 24 hours, and finally peel off from the petri dish to obtain a transparent, The flexible, unsupported photocatalytic membrane is a titanate nanosheet photocatalytic membrane material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com