High detection rate GaN-based Schottky ultraviolet detector using graphene

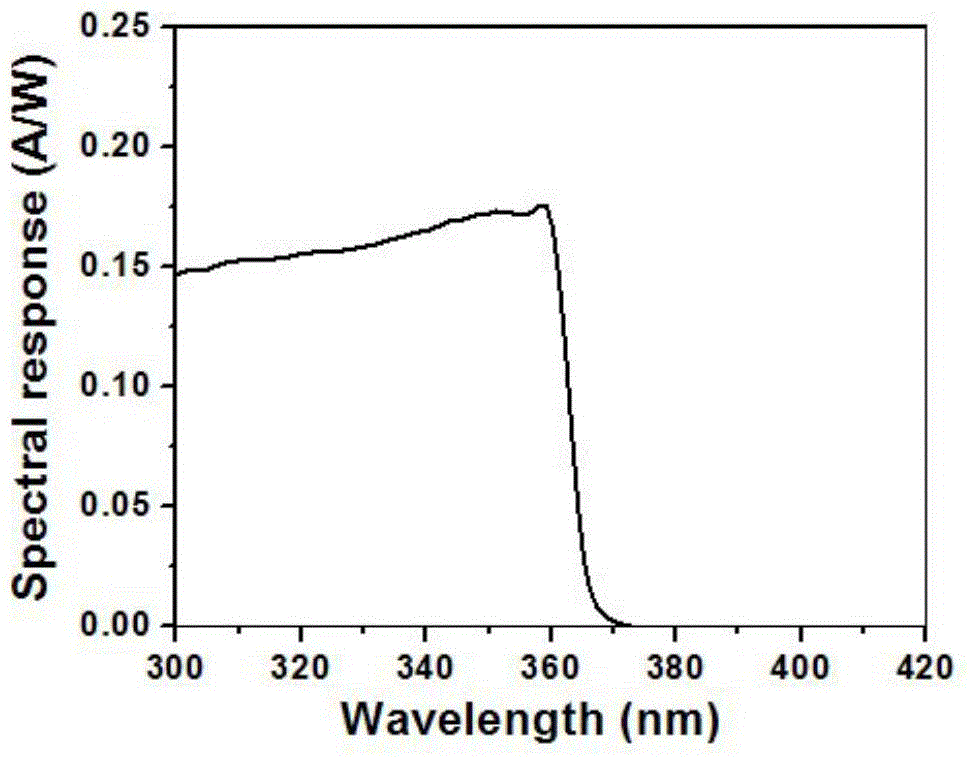

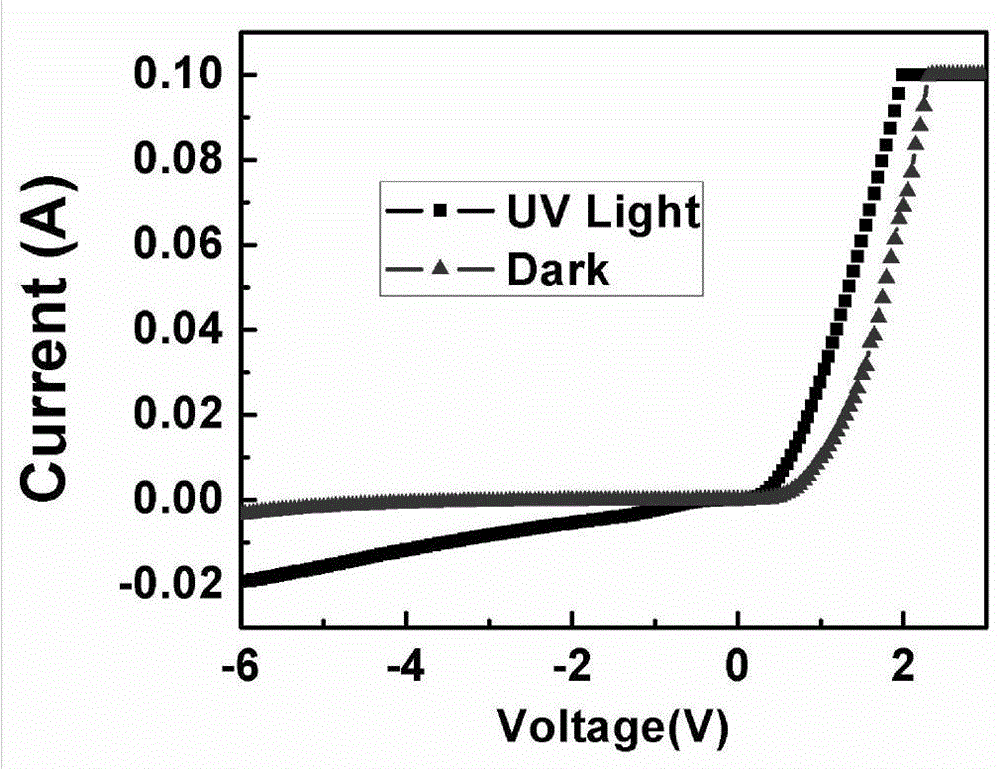

An ultraviolet detector, gallium nitride-based technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of unsatisfactory metal materials, detection rate impact, light transmittance drop, etc., to enhance the built-in electric potential field, The effect of increasing the detection rate and responsivity and increasing the quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

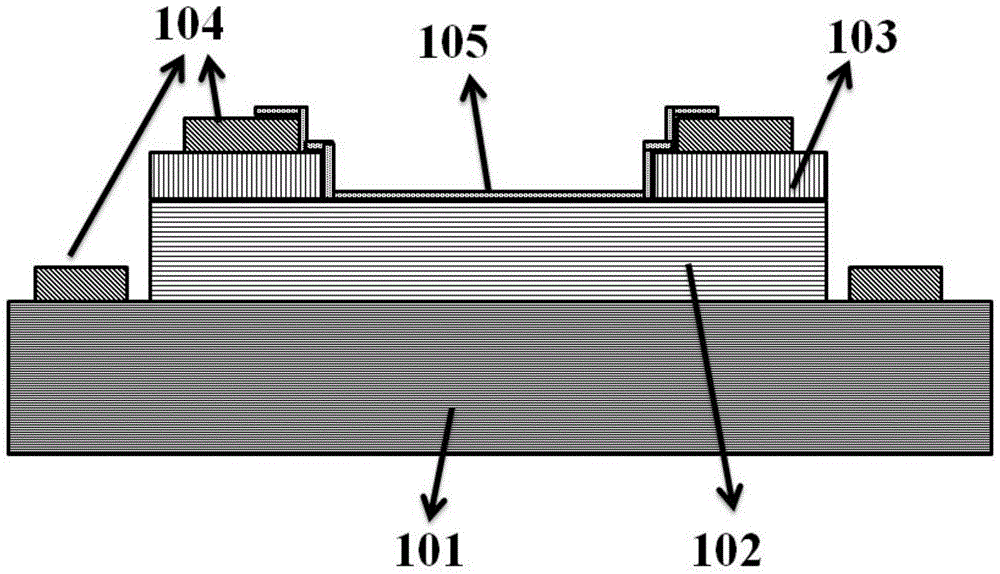

[0029] Step 1. Use metal organic chemical vapor deposition (or molecular beam epitaxy system, liquid phase epitaxy technology, etc.) to sequentially produce heavily doped n-type gallium nitride 101 and lightly doped sapphire (or silicon wafer, silicon carbide, etc.) Hetero n-type gallium nitride 102.

[0030] Step 2. Cleaning, photolithography, and etching of the epitaxial wafer to form a mesa structure, such as heavily doped n-type gallium nitride 101 and lightly doped n-type gallium nitride 102.

[0031] Step 3: Growing a layer of silicon dioxide, and performing photolithography and etching to form a silicon dioxide insulating layer 103.

[0032] Step 4. Photoetch the electrode pattern, sputter or evaporate to produce the metal electrode 104.

[0033] Step 5: Transfer graphene to the surface of the device, photoetch the graphene pattern, and plasma etch the graphene to form a graphene film 105. The plasma etching gas is oxygen, the flow rate is 10-70L / min, the power is 50-100W, and...

Embodiment 2

[0038] Step 1. Use metal organic chemical vapor deposition (or molecular beam epitaxy system, liquid phase epitaxy technology, etc.) to sequentially fabricate heavily doped n-type gallium nitride 101 on sapphire (or silicon wafer, silicon carbide, etc.), lightly doped Hetero n-type gallium nitride 102.

[0039] Step 2. Use inductively coupled plasma to etch the surface of the epitaxial wafer to an etching depth of 10-50 nm to increase the surface defect density of the epitaxial wafer.

[0040] Step 3. Cleaning, photolithography, and etching of the epitaxial wafer to form a mesa structure, such as heavily doped n-type gallium nitride 101 and lightly doped n-type gallium nitride 102.

[0041] Step 4. Grow a layer of silicon dioxide, and perform photolithography and etching to form a silicon dioxide insulating layer 103.

[0042] Step 5. Photoetch the electrode pattern, sputter or evaporate to produce the metal electrode 104.

[0043] Step 6, transferring graphene to the surface of the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com