Compound metal oxide water oxidation catalyst and electrostatic spinning preparation method thereof

A composite oxide, electrospinning technology, applied in the preparation of electrospinning technology, amorphous composite metal oxide water oxidation catalyst field, can solve the problem of low abundance, unstable catalytic activity, and limit the practical application of water oxidation catalyst and other problems, to achieve the effects of stable catalytic activity, excellent electrocatalytic water oxidation activity, and simple and easy technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

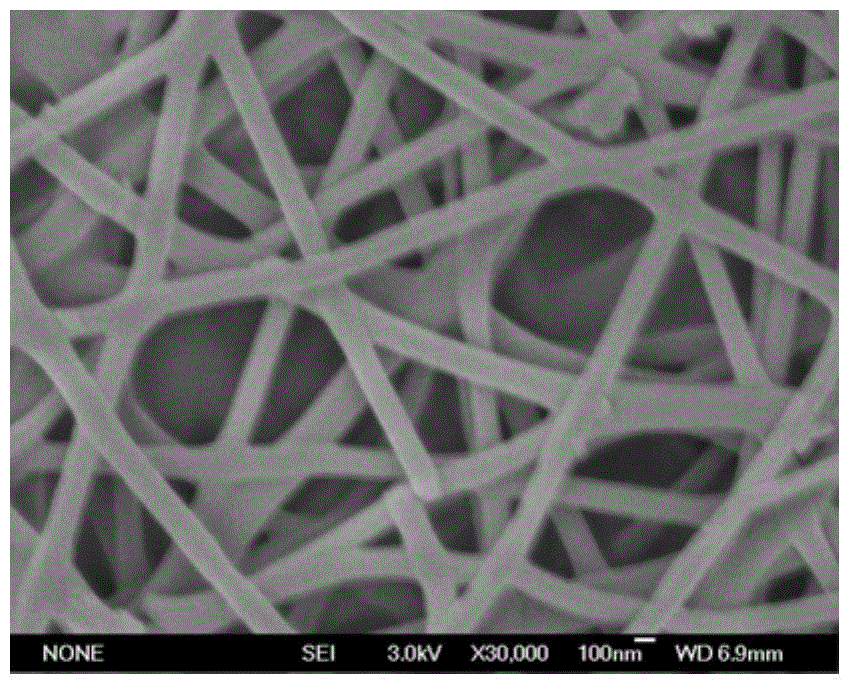

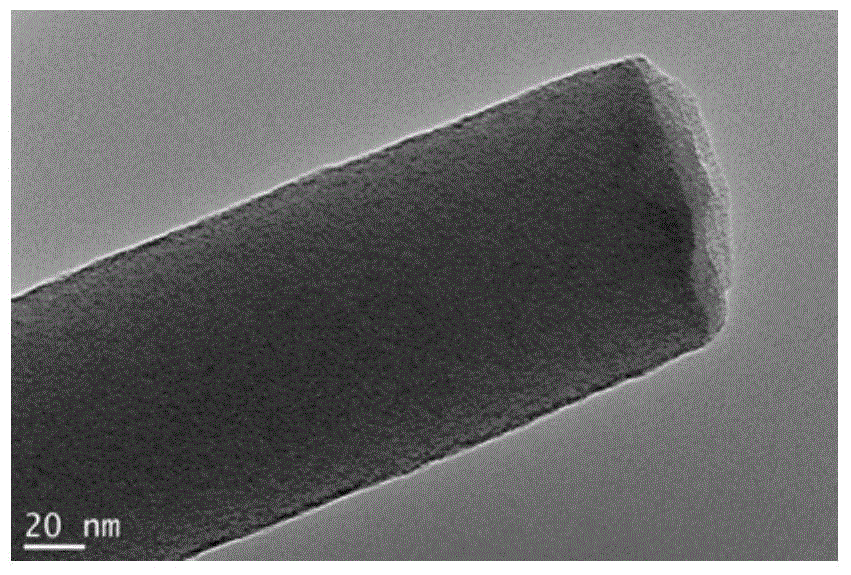

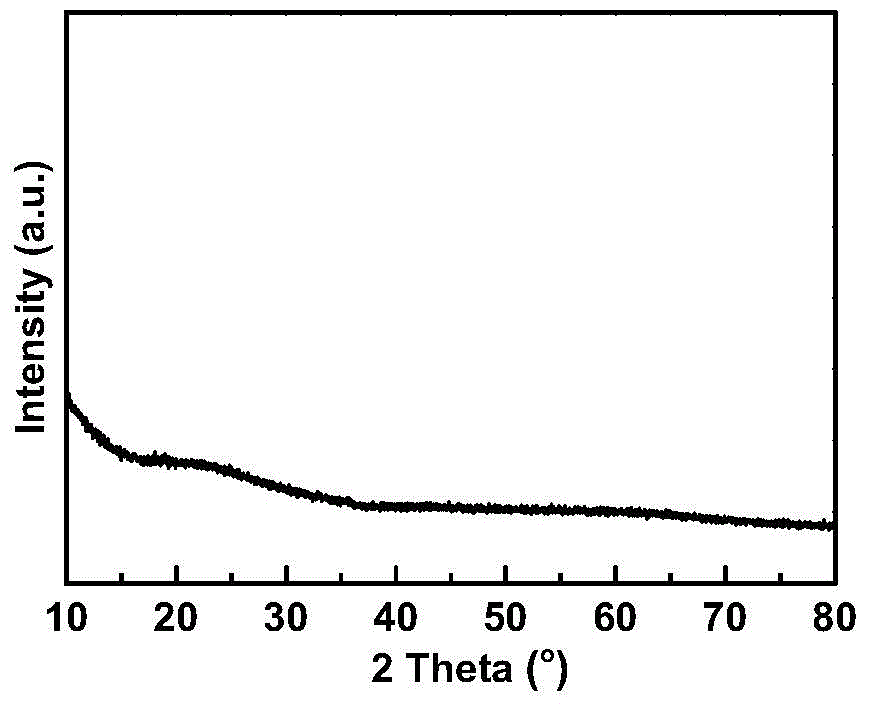

[0026] Add 1 g of polyvinylpyrrolidone (PVP) into 10 mL of ethanol and 3 mL of DMF mixed solvent, and stir at room temperature for 30 min until the PVP is completely dissolved and becomes a colorless transparent solution. Under stirring, 0.5 mmol of nickel nitrate hexahydrate and 1 mmol of iron acetylacetonate were sequentially added, and stirred at room temperature for 12 hours to obtain a uniform solution. Pour the solution into a 5mL syringe, the inner diameter of the needle is 0.41mm, the aluminum foil is used as the cathode receiving plate, and the nanofiber product is collected, the distance between the aluminum foil and the two pole plates of the needle is 22cm, the applied voltage is 23kV, the temperature is 25°C, and the humidity is 20% , followed by electrospinning, and nanofiber precursors were obtained on the receiving plate after 25 h. The nanofiber precursor was dried at 70° C. for 24 hours, and the obtained dry nanofiber precursor was calcined at 250° C. for 3 h...

Embodiment 2

[0030] Same as Example 1, just change the quality of iron acetylacetonate into 0.5mmol. The electrocatalytic performance of the obtained sample: under alkaline conditions, the current density of the electrode made of this material reaches 10mA / cm 2 , its overpotential is 341mV.

Embodiment 3

[0032] Same as Example 1, just change the quality of iron acetylacetonate into 0.25mmol. The electrocatalytic performance of the obtained sample: under alkaline conditions, the current density of the electrode made of this material reaches 10mA / cm 2 , its overpotential is 373mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com