Preparation method of high-performance nitrogen-doped carbon-coated lithium titanate composite anode material of lithium ion battery

A nitrogen-doped carbon, ion battery technology, applied in battery electrodes, titanates, titanium compounds, etc., can solve the problems of rapid specific capacity decay and poor conductivity of lithium titanate, and achieve excellent conductivity, low price, enhanced Effects of Conductivity and Electrochemical Reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

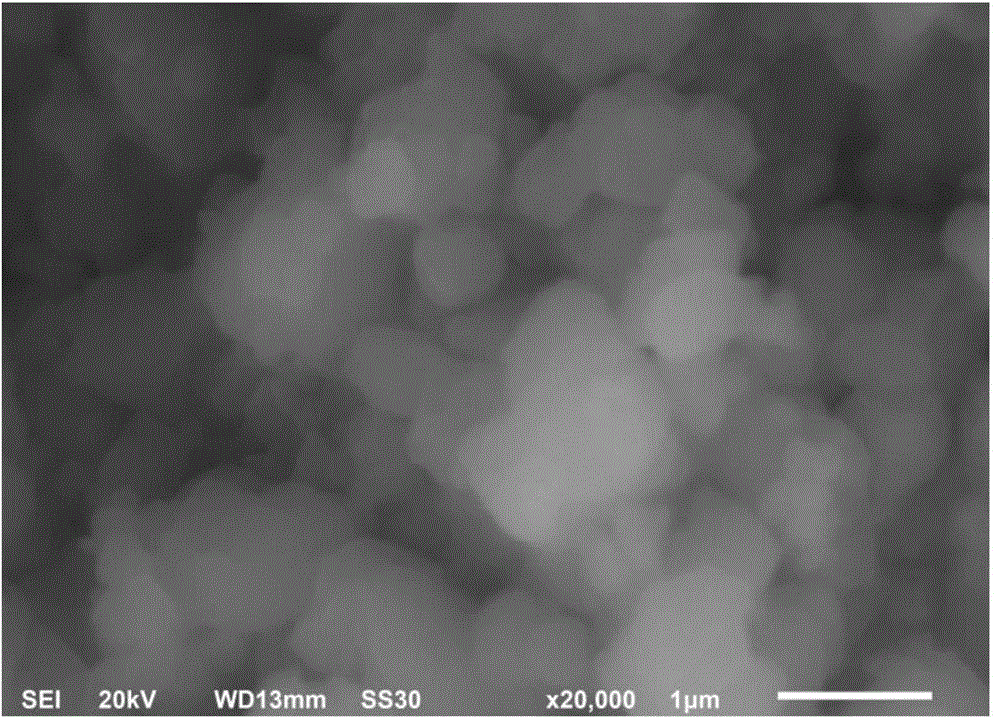

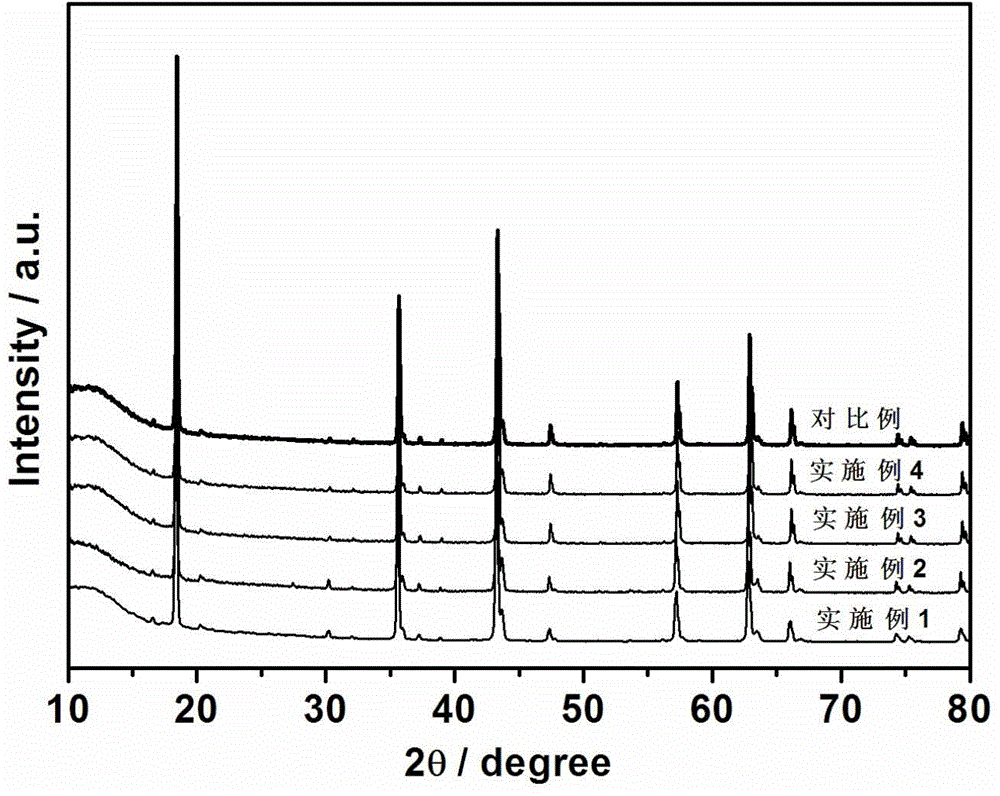

[0027] A preparation method of a high-performance nitrogen-doped carbon-coated lithium titanate composite lithium-ion battery negative electrode material, the steps are as follows:

[0028] Lithium hydroxide, nano-titanium dioxide and melamine are added to the ball mill (the speed of the ball mill is 2000 rpm), and anhydrous ethanol is used as the medium for ball milling for 1 hour (the speed of the ball mill is 2000 rpm), wherein lithium hydroxide and nano The mass ratio of titanium dioxide is 1:1, and the mass of melamine is 2.5% of the sum of the mass of lithium hydroxide and nano titanium dioxide. The slurry obtained after ball milling is spray-dried to obtain a powder mixture material. The obtained powder mixture was calcined in a nitrogen atmosphere from room temperature to 700°C at a rate of 3°C / min, kept at this temperature for 3 hours, and cooled to obtain the primary product of nitrogen-doped carbon-coated lithium titanate composite material. The initial product was...

Embodiment 2

[0030] A preparation method of a high-performance nitrogen-doped carbon-coated lithium titanate composite lithium-ion battery negative electrode material, the steps are as follows:

[0031] Lithium carbonate, nano-titanium dioxide and melamine are joined in the ball mill (the rotating speed of ball mill is 2000 revs / min), and with dehydrated alcohol as medium ball milling 1 hour (the rotating speed of ball mill is 2000 revs / min), wherein lithium carbonate and nano-titanium dioxide The ratio of the amount of substances is 0.5:1, and the mass of melamine is 7.5% of the sum of the mass of lithium carbonate and nano titanium dioxide. The slurry obtained after ball milling is spray-dried to obtain a powder mixture material. The resulting powder mixture was calcined in an argon atmosphere from room temperature to 700°C at a rate of 3°C / min, and kept at a temperature of 3 hours. After cooling, the primary product of nitrogen-doped carbon-coated lithium titanate composite material was...

Embodiment 3

[0033] A preparation method of a high-performance nitrogen-doped carbon-coated lithium titanate composite lithium-ion battery negative electrode material, the steps are as follows:

[0034] Lithium hydroxide, nano-titanium dioxide and melamine are added to the ball mill (the speed of the ball mill is 2000 rpm), and anhydrous ethanol is used as the medium for ball milling for 1 hour (the speed of the ball mill is 2000 rpm), wherein lithium hydroxide and nano The mass ratio of titanium dioxide is 1:1, and the mass of melamine is 5% of the sum of the mass of lithium hydroxide and nano titanium dioxide. The slurry obtained after ball milling is spray-dried to obtain a powder mixture material. The obtained powder mixture was calcined in a nitrogen atmosphere from room temperature to 700°C at a rate of 3°C / min, kept at this temperature for 3 hours, and cooled to obtain the primary product of nitrogen-doped carbon-coated lithium titanate composite material. The initial product was m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com