Industrial organic waste gas treatment and cleaning process

A technology of organic waste gas and organic gas, which is applied in the field of activated carbon steam desorption cleaning process, can solve the problems of increasing the load of the adsorption tower and heating air energy consumption, unused latent heat of steam, and increasing the load of the adsorption tower, etc., to meet the requirements of clean production , Improve the efficiency of oil-water separation and reduce the solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

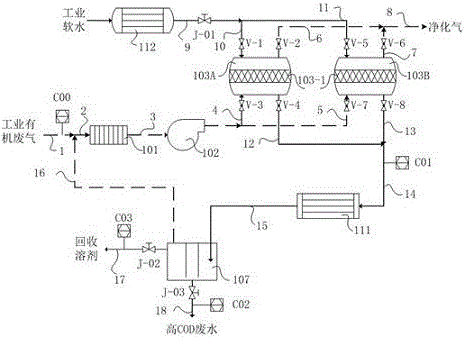

Image

Examples

Embodiment 1

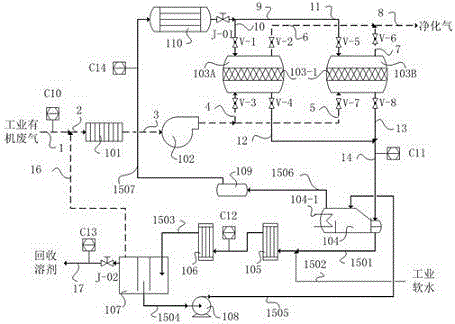

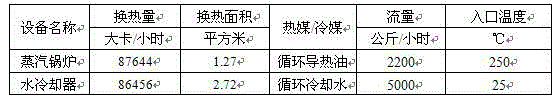

[0077] The source, composition and process parameters of industrial organic waste gas are the same as in Comparative Example 1, and its flow rate and stream composition are shown in Table 11-1C10. Adopt cleaning process of the present invention to handle (see figure 2), the organic waste gas from the main pipe 1 and the non-condensable gas from the discharge pipeline 16 of the oil-water separator (107) is mixed in the pipeline 2, connected to the surface cooler (101) for cooling, cooled to below 40°C, filtered, and blown by the fan (102) Boost the pressure and send it to the adsorption tower A (103A). The VOCs in the gas are adsorbed and purified by the activated carbon layer (103-1). The designed adsorption efficiency is not less than 98%, and the purified gas is discharged up to the standard. Each adsorption tower is filled with columnar granular activated carbon, and is equipped with a water cooling coil to remove the heat of adsorption, prevent the activated carbon layer ...

Embodiment 2

[0087] The source, composition and process parameters of industrial organic waste gas are the same as in Comparative Example 2, and its flow rate and stream composition are shown in Table 12-1C10. Adopt cleaning process of the present invention to handle (see figure 2 ), the specific process and operation are the same as in Example 1.

[0088] Table 12-1 Simulation calculation results of electrostatic spray painting organic waste gas cleaning treatment process in machinery industry#

[0089]

[0090] #: The desorption solvent recovery rate of the cleaning process (%) = the sum of the organic matter flow rate of "C11" × 100 / the sum of the organic matter flow rate of "C13", and the calculation result is 84.75%.

Embodiment 3

[0095] The source, composition and process parameters of industrial organic waste gas are the same as in Comparative Example 3, and the flow rate and stream composition are shown in Table 13-1C10. Adopt cleaning process of the present invention to handle (see figure 2 ), except that the adsorption tower is filled with honeycomb activated carbon, other specific processes and operations are the same as in Example 1.

[0096] Table 13-1 Simulation calculation results of organic waste gas cleaning treatment process from semiconductor integrated circuit production#

[0097]

[0098] #: The desorption solvent recovery rate of the cleaning process (%) = the sum of the organic matter flow rate of "C11" × 100 / the sum of the organic matter flow rate of "C13", and the calculation result is 92.83%.

[0099] Compared with Comparative Example 3, the heat used for desorption steam heating is reduced from 3857 kcal / hour to 403 kcal / hour, saving energy consumption by 89.25% (calculation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com