a wallboard

A technology of wall panels and metal panels, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of easy corrosion of exterior wall decorative panels, easy water seepage in joint gaps, poor radiation resistance, etc. The preparation process is simple and feasible, the compatibility is reasonable, and the effect of water and moisture resistance is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

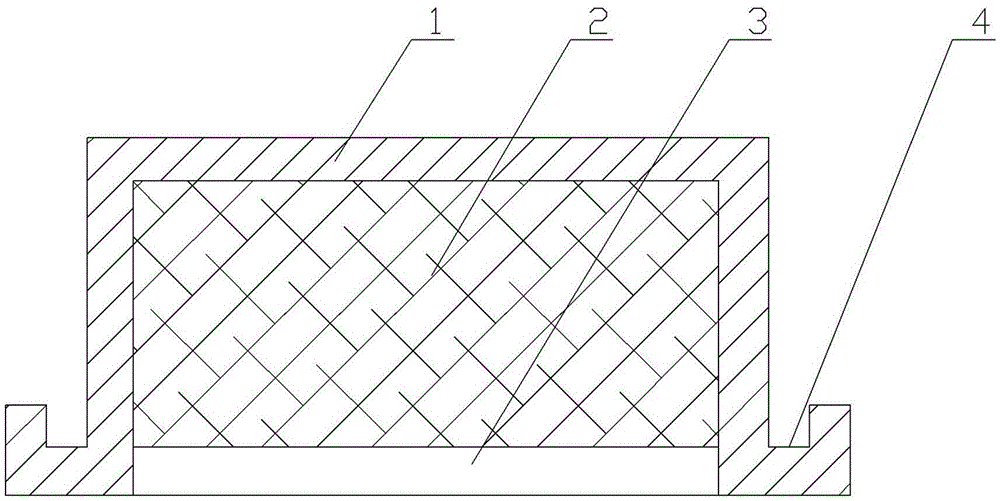

[0023] A kind of wallboard, it comprises gypsum core material layer 2, is provided with veneer layer 3 below described gypsum core material layer 2; The metal plate layer 1 of the metal thread layer, the underside of the metal plate layer 1 on the two sides is provided with a gutter 4 that facilitates the flow of rainwater;

[0024] The gypsum core material layer is prepared from the following raw materials in parts by weight:

[0025] 70 parts of water, 2 parts of ordinary Portland cement, 3 parts of diatomite, 3 parts of lithium bentonite, 5 parts of polylactic acid, 5 parts of starch ether, 5 parts of slaked lime, 6 parts of borax, 6 parts of dolomite, hydroxymethyl 10 parts of cellulose, 15 parts of egg shells, 15 parts of straw, 20 parts of fly ash, and 50 parts of gypsum powder.

[0026] The preparation method of above-mentioned gypsum core material layer comprises the steps:

[0027] Step 1): Weighing each raw material according to the weight part for subsequent use; ...

Embodiment 2

[0036] A kind of wallboard, it comprises gypsum core material layer, the underside of described gypsum core material layer is provided with veneer layer; The top and both sides of described gypsum core material layer are covered with antistatic paint and wire thread layer The metal plate layer, the bottom of the metal plate layer on the two sides is provided with a water tank to facilitate the flow of rainwater;

[0037] The gypsum core material layer is prepared from the following raw materials in parts by weight:

[0038] 80 parts of water, 3 parts of ordinary portland cement, 4 parts of diatomite, 5 parts of lithium bentonite, 7 parts of polylactic acid, 7 parts of starch ether, 7 parts of slaked lime, 9 parts of borax, 9 parts of dolomite, hydroxymethyl 12 parts of cellulose, 18 parts of egg shells, 18 parts of straw, 30 parts of fly ash, and 60 parts of gypsum powder.

[0039] The preparation method of above-mentioned gypsum core material layer comprises the steps:

[0...

Embodiment 3

[0049] The performance parameter test of the gypsum core material layer prepared in Example 1 and Example 2 of the present invention: the specific test results are shown in Table 1, and the Saint-Gobain formaldehyde-purified gypsum core material layer commonly used in the market is used as a comparison.

[0050] Table 1

[0051] group

[0052] After testing, the gypsum core layer prepared in Example 2 of the present invention can remove more than 59% of free formaldehyde in the living room (39% for the control group), and more than 38% of benzene. It can be seen that the gypsum core material layer prepared by the present invention has good waterproof and moisture resistance, is environmentally friendly and pollution-free, and can effectively remove harmful gases such as formaldehyde and benzene; performance parameters such as compressive strength, thermal conductivity and 2h water absorption thickness expansion rate are all equal. It has been greatly improved and has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com