A kind of calcium-aluminosilicate glass-based low-temperature co-fired ceramic material and preparation method thereof

A technology of low-temperature co-fired ceramics and calcium-aluminum-silicate glass, which is applied in the field of low-temperature co-fired ceramics and can solve problems such as unfavorable industrial production and low thermal conductivity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the present invention also provides a method for preparing a calcium-aluminosilicate glass-based low-temperature co-fired ceramic material, comprising the following steps:

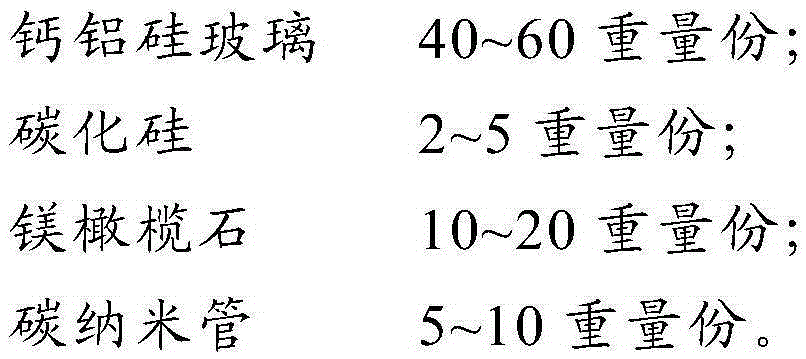

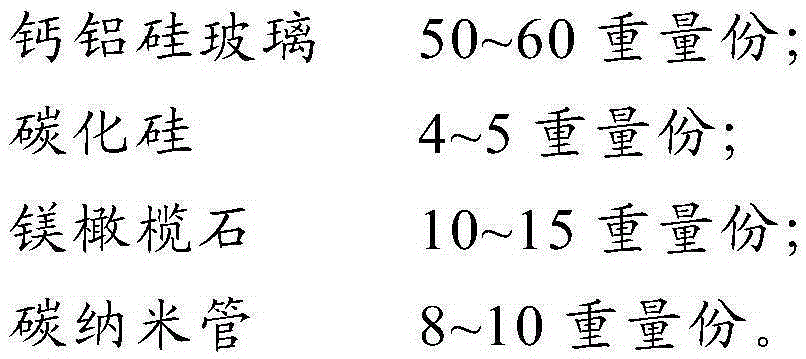

[0034] After mixing 40-60 parts by weight of calcium-aluminosilicate glass, 2-5 parts by weight of silicon carbide, 10-20 parts by weight of forsterite and 5-10 parts by weight of carbon nanotubes, adding ethanol, ball milling and drying to obtain low-temperature co-fired ceramic powder;

[0035] Adding solvent, binder, plasticizer, dispersant and wetting agent to the low-temperature co-fired ceramic powder, mixing uniformly, tape-casting, drying and sintering to obtain low-temperature co-fired ceramic material.

[0036] Wherein, the calcium aluminum silicate glass is made of SiO 2 、Al 2 o 3 and CaO preparation. The present invention uses calcium-aluminosilicate glass as the basic glass, and its main crystal phase is silicate p-wollastonite with a chain structure, which is arran...

Embodiment 1

[0044] Step (1) Weigh 50g of calcium-aluminosilicate glass, 5g of SiC powder, 20g of forsterite and 5g of carbon nanotubes, mix them, add an appropriate amount of ethanol, put them in a planetary ball mill and mix them for 3 hours at 300r / min, and then Dry at 120°C to obtain low temperature co-fired ceramic material powder.

[0045] Step (2) The mass percent of organic matter added to the low-temperature co-fired ceramic material powder is: trichlorethylene 76%, polyvinyl butyral 14%, dibutyl phthalate 3%, triglyceride A solution of 4.8% glyceride and 2.2% polyoxyethylene ester, uniformly mixed, defoamed, cast, dried, heated to 450°C for 2 hours, then heated to 500°C for 5 hours, then heated to 650°C for heat preservation After 2 hours, a lime-aluminosilicate glass-based low-temperature co-fired ceramic material was obtained.

[0046] The lime-aluminosilicate glass-based low-temperature co-fired ceramic material prepared in this example was measured. After testing, the therm...

Embodiment 2

[0048] Step (1) Weigh 40g of calcium-aluminosilicate glass, 5g of SiC powder, 20g of forsterite and 10g of carbon nanotubes, mix them, add an appropriate amount of ethanol, put them in a planetary ball mill and mix them for 3 hours at 300r / min, and then Dry at 120°C to obtain low temperature co-fired ceramic material powder.

[0049] Step (2) The mass percent of organic matter added to the low-temperature co-fired ceramic material powder is: trichlorethylene 76%, polyvinyl butyral 14%, dibutyl phthalate 3%, triglyceride A solution of 4.8% glyceride and 2.2% polyoxyethylene ester, uniformly mixed, defoamed, cast, dried, heated to 450°C for 2 hours, then heated to 500°C for 5 hours, then heated to 650°C for heat preservation After 2 hours, a lime-aluminosilicate glass-based low-temperature co-fired ceramic material was obtained.

[0050] The lime-aluminosilicate glass-based low-temperature co-fired ceramic material prepared in this example was measured. After testing, the ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com