Method for preparing light thermal-insulating wall material by virtue of coal gangue

A technology of thermal insulation walls and coal gangue, applied in the field of building materials, can solve the problems of complex wall structure, easy shrinkage and cracking, waste of resources, etc., to achieve environmental protection and improvement, saving natural mineral resources, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

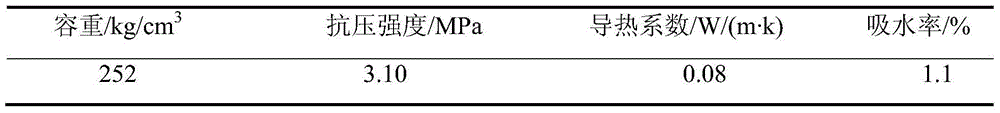

Embodiment 1

[0030] A method for preparing light-weight thermal insulation wall materials by using coal gangue. The raw materials and their mass percentages are: 88% coal gangue, 3.8% dolomite, 7% cullet, 1.2% foaming agent, and the coal gangue It is clay rock gangue, and the foaming agent is a mixture of silicon carbide and calcium sulfate, wherein the mass ratio of silicon carbide and calcium sulfate is 1:1, and its preparation method comprises the following steps:

[0031] 1) Put the weighed various raw materials into the ball mill together, and carry out dry grinding. In order to reduce the agglomeration of the powder in the grinding process and improve the homogenization effect, triethanolamine is added in a proportion of 0.2‰ of the mass of the solid raw material as Dispersant, ground to a fineness of ≤50 μm to obtain a mixed powder;

[0032] 2) The obtained mixed powder is made into a granular powder of 0.5 to 10 mm by a granulator;

[0033] 3) Gained granular powder is directly lo...

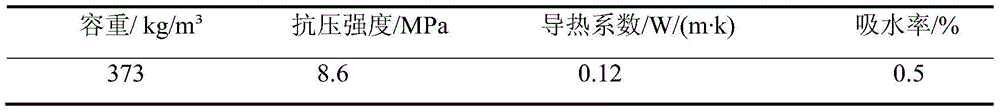

Embodiment 2

[0040] A method for preparing light-weight thermal insulation wall materials by using coal gangue. The raw materials and their mass percentages are coal gangue 71%, albite 18%, magnesite 8.5%, foaming agent 2.5%, foaming agent Be the mixture of silicon carbide and iron oxide, wherein the mass ratio of silicon carbide and iron oxide is 0.5:2, and its preparation method comprises the following steps:

[0041] 1) Put all the weighed raw materials into the ball mill together, and carry out dry grinding. In order to reduce the agglomeration of the powder during the grinding process and improve the homogenization effect, add diethylene glycol at a ratio of 0.3‰ of the solid raw material mass Alcohol is used as a dispersant, and ground to a fineness of ≤50 μm to obtain a mixed powder;

[0042] 2) The obtained mixed powder is made into a granular powder of 0.5-10mm through a granulator; the obtained granular powder is directly put into an assembled refractory mold coated with alumina ...

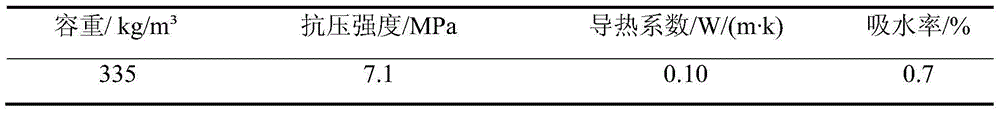

Embodiment 3

[0049] A method for preparing light-weight thermal insulation wall materials by using coal gangue. The composition mass percentage of each raw material is: 82% coal gangue, 6% potassium feldspar, 4% iron tailings, 6.4% magnesite, and 1.6% foaming agent , described coal gangue is that described blowing agent is the mixture of silicon carbide and calcium sulfate, and wherein the mass ratio of silicon carbide and calcium sulfate is 0.6:1, and its preparation method comprises the following steps:

[0050] 1) Put all the weighed raw materials into the ball mill together, and carry out dry grinding. In order to reduce the agglomeration of the powder during the grinding process and improve the homogenization effect, add diethylene glycol at a ratio of 0.3‰ of the solid raw material mass Alcohol is used as a dispersant, and ground to a fineness of ≤50 μm to obtain a mixed powder;

[0051] 2) The obtained mixed powder is made into a granular powder of 0.5-10mm through a granulator; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com