Biofilter suitable for sewage treatment of water-network type village ditches

A biological filter and filter technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as easy breeding of mosquitoes and flies, complex operation and management, and achieve structural Simple, low investment and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

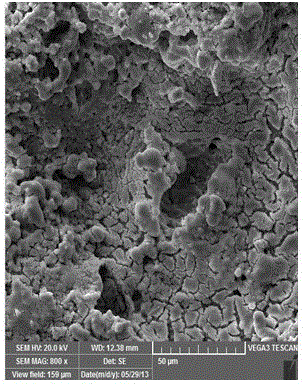

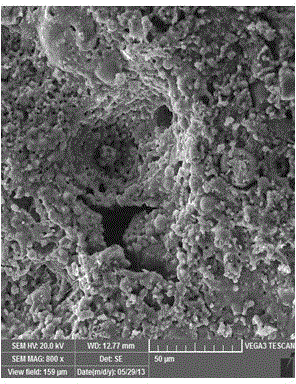

[0044] Embodiment 1, the development of filter material

[0045] 1. Preparation steps of filter material

[0046] 1) Dry and crush the fly ash, clay and coal powder of the power plant, pass through a 200-mesh standard sieve, mix them evenly according to the ratio of 7:2:1, add water to plasticize them into balls, and place them in an oven at 180°C for 3 hours. After cooling, place it in a muffle furnace for temperature programming, control the preheating temperature to 500°C, preheating time for 25 minutes, and then raise the temperature to 1050°C for sintering for 20 minutes to complete the entire preparation process. After cooling, take it out to get a particle size of 5-8mm, a moisture content of 22.5%, and a bulk density of 788kg / m 3 , the true density is 1.82g / m 3 , cylinder compressive strength is 5.2MPa, specific surface area is 5.28m 2 / g water treatment ceramsite filter material.

[0047] 2) Use the above ceramsite filter material with 1mol / L FeCl 3 The solution ...

Embodiment 2

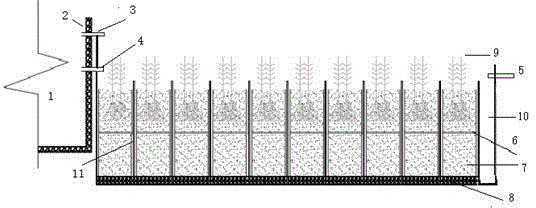

[0054] Embodiment 2, biofilter design and operation

[0055] The setting of the water inlet of the biological filter is to make full use of the terrain of the water network and the gravity of the water. The sewage naturally falls from the dam to the front of the filter through the water inlet pipe. During the falling process, the sewage carries a large amount of oxygen in the air, making the filter An aerobic zone is formed at the front end and the upper end to provide an environment suitable for the survival and growth of aerobic microorganisms; since the water level of the upstream pond and ditch changes with the seasons, the inlet pipe of the filter is designed to be two upper and lower pipes to adapt to this reality. Then the sewage flows along the length of the pool through the baffle plate, passing through each cell, and the cell is filled with a self-made filter material with the function of synchronous denitrification and phosphorus removal. Microorganisms growing on t...

Embodiment 3

[0059] Embodiment 3, the reuse of ceramsite filter material after sewage treatment

[0060] When the adsorption of the filter material reaches saturation, the filter material in the filter material basket can be taken out for reuse. In the process of sewage treatment, the filter material adsorbs nutrients such as organic matter, nitrogen and phosphorus, and the K contained in its main component fly ash 2 O,Na 2 O, MgO, CaO, Fe 2 o 3 ,Al 2 o 3 , SiO 2 And phosphorus, copper, zinc, manganese and other rich minerals and trace elements are indispensable elements in the process of plant growth. It can be mixed with soil according to a certain mass fraction, and used as an organic fertilizer for non-edible plants such as flowers, grasslands, gardens, etc., to achieve the purpose of resource utilization. Because of concerns that the use of saturated fly ash filter material as fertilizer will cause soil compaction and excessive heavy metals, a heavy metal dissolution test was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com